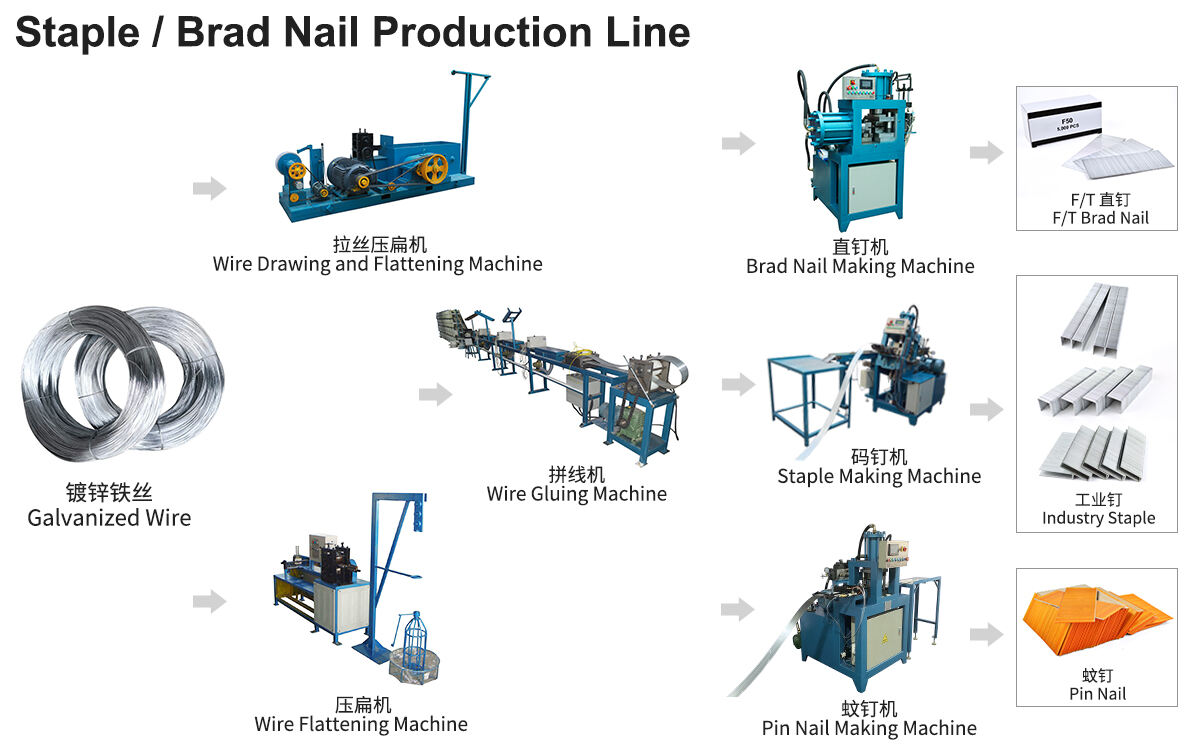

Staple/Brad Nail/ Pin Nail/Hog Ring/High Carbon Steel Staple Fully Automatic Production Line

Production Process

First, flattening the wire into desired diameter by wire flattening machine. Then, gluing the wire into wire band by gluing machine.Finally, forming staple by staple/nail making machine.(We have staple / nail making machine for different series of nail)

Wire Flattening Machine

Flattening is the first step in the whole production process.Flatten the raw material into the appropriate thickness as required.The motor power is 3 kw and the wire thickness can be adjusted arbitrarily. The working speed is 0-300 meters per minute.

Wire Gluing Machine

It also called wire band machine.Gluing the flattening wire into wire band with A glue and B glue.After the glue drying,the wire band can be used to produce staple/nail.

The width of wire band is 150mm.The working speed is 0-20m.The gluing machine covers an area of 21-25 meters, and can also be designed according to the length of the customer's workshop.

Staple / Nail Making Machine

This is the last process in production—— To press and form the wire band to the final product staples/ brad nails. This machine has abandoned the traditional heavy punch press, adopting the hydraulic system as the executive part, utilizing the PLC system, which has the characteristics of safe operation, stable performance, low noise and so on. Compared with the traditional punch machine, the speed is greatly increased. We also can customize the mold according to the customer's demand.

EN

EN

AR

AR

BG

BG

CS

CS

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

LT

LT

SR

SR

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

AZ

AZ

KA

KA

BN

BN

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

KK

KK

UZ

UZ