Maintenance and care of Ky Nailing equipment

Understanding Ky Nailing Equipment

Ky Nailing Equipment includes all sorts of tools that builders and woodworkers rely on when they need to drive nails into materials. These machines have been designed to work with precision while saving time on the job site. Whether someone is putting together furniture or constructing an entire building, these tools make sure nails go in straight and stay put without damaging surrounding material. The product line ranges from basic staple guns used around the house to heavy duty hydraulic nailers capable of handling thousands of fasteners per day. For contractors working on everything from small repair jobs to large scale manufacturing operations, there's probably a Ky tool that fits their particular requirements.

Tools built for boosting productivity make nailing jobs much easier and more accurate, something that matters a lot when work crews need to keep moving quickly on construction sites or manufacturing floors. These machines take over what used to be tedious handwork, cutting down on fatigue while getting more done in less time. Many modern models come equipped with things like programmable logic controllers (PLCs) that handle complex sequences automatically. Workers no longer have to manually adjust settings between different tasks, which means fewer mistakes and better consistency across projects from start to finish.

Getting familiar with Ky Nailing Equipment matters a lot for anyone working on construction sites, especially those in charge of operations or managing projects. When folks know how these machines actually work day to day, they get much better results while staying safe during operation. Plus, knowing what makes them tick helps when things go wrong or regular maintenance becomes necessary. Proper care extends how long the equipment lasts before needing replacement, plus keeps the final product looking good. Taking time to really understand all the little details about running and keeping up Ky Nailing Gear pays off big time at worksites where productivity counts and deadlines loom large.

Importance of Maintenance for Ky Nailing Equipment

Keeping Ky Nailing Equipment in good shape through regular maintenance makes all the difference for how long it lasts and how well it works. These special tools get used constantly on job sites and in workshops across the country. When people neglect them, parts start breaking down faster than expected. A quick daily check of air pressure settings and occasional oiling of moving components goes a long way toward preventing breakdowns during critical moments. Some industry reports suggest that sticking to a basic maintenance schedule actually doubles the useful life of these machines in real world conditions. That kind of reliability matters when time equals money on any construction project.

When maintenance gets ignored, things tend to go south pretty fast. Equipment breaks down, which means projects get delayed and fixing those problems ends up costing way more money than planned. Take a broken nailer for instance it stops everything dead in its tracks, slows down work进度, and throws off deadlines left right and center. The worst part? Those repair bills pile up faster than anyone expects, eating into budgets meant for other important stuff on site. Regular maintenance isn't just good practice it's practically essential if we want our operations running smoothly without blowing through cash. Lubricating parts when needed, keeping tools clean, and checking them over regularly aren't fancy solutions but they work wonders for keeping Ky Nailing Equipment dependable over time. Most contractors know this from experience after all, nobody wants their crew standing around waiting for repairs during critical phases of construction.

Routine Maintenance Checklist for Ky Nailing Equipment

Keeping Ky Nailing Equipment well maintained makes all the difference when it comes to how long it lasts and how well it performs day after day. A good starting point is daily upkeep routines that keep things running without hiccups. After every job, give the machine a quick wipe down to clear away dust and bits of wood that might get stuck somewhere important. Don't forget to look around for places where parts seem worn out or damaged in some way. Spotting small problems now saves headaches later on when bigger repairs become necessary. And remember to apply lubricant to those moving components from time to time. This helps reduce the grinding between parts which naturally happens over extended use.

Equipment needs regular care every week or so to stay working right. First thing to do is look at those air filters - if they're dirty or blocked, that's going to mess with how well everything breathes and works efficiently. A quick check here goes a long way. Then spend some time testing out where nails go during operation. Run through a couple test shots to see if things are hitting where they should be. While doing this, take a moment to walk around the machine and grab a wrench for any screws or bolts that feel wobbly. Tightening them up keeps everything stable and accurate when it matters most.

Regular monthly checks need to go beyond just looking at individual pieces and instead examine how all the components work together in the full equipment system. Take time during these inspections to spot parts showing signs of wear or stress that might fail soon. Most technicians find recalibration necessary after several months of regular use to keep everything running true. When worn parts get replaced before they actually break down, it saves a lot of headaches later on when production schedules are disrupted. Stick with this kind of maintenance schedule and most machines will last longer while maintaining better performance levels throughout their service life.

Troubleshooting Common Issues in Ky Nailing Equipment

When using Ky Nailing Equipment, operators may encounter common problems such as jamming, inconsistent nail depth, and air leaks. These issues can interrupt workflow and reduce efficiency if not addressed promptly. Regular monitoring can minimize these occurrences and ensure smooth operation.

Want to tackle these issues? Here are some real world fixes that actually work. When nails get stuck or jammed up, first check if there's anything blocking the path of the nails in the machine. Sometimes just clearing out debris from inside will solve the problem. Dealing with nails going in too deep or not far enough? The air pressure settings probably need tweaking. Start by adjusting it slightly higher or lower until the nails seat correctly in the material. Air leaks can be tricky but worth fixing. Look closely at all the hoses and seals around the tool. Small cracks or worn spots let precious air escape, which affects how well everything works. Replace any damaged parts immediately before they cause bigger problems down the line.

In situations where issues persist despite troubleshooting efforts, seeking professional assistance is prudent. Persistent problems could indicate underlying issues that, if ignored, might cause severe damage to the equipment. A professional can identify the root cause and provide a comprehensive solution, ensuring your equipment returns to full operational capacity.

Products for Optimal Performance of Ky Nailing Equipment

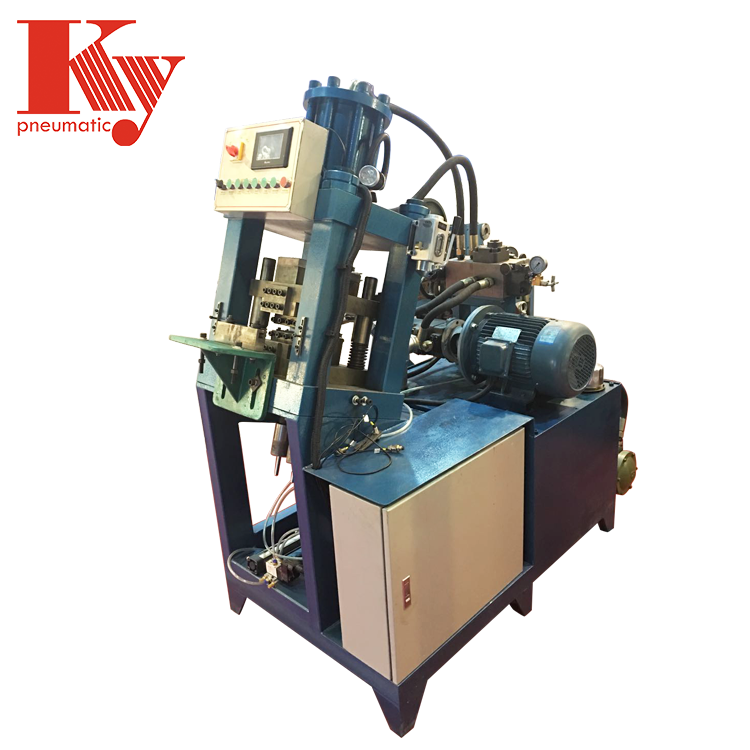

The Auto Pneumatic Brad Nail Making Machine stands out as a game changer for anyone working with Ky Nailing Equipment. What makes this machine so valuable? Well, it cuts down on wasted time and effort across the board. The operator doesn't need to spend hours manually feeding materials anymore since everything flows through automatically. Plus, the dual operation feature means workers can handle multiple tasks at once instead of waiting between cycles. When facing those big construction jobs that require thousands of nails daily, this machine keeps up without breaking a sweat. Contractors who've switched to this system report finishing projects weeks ahead of schedule while maintaining consistent quality throughout their work.

The way this machine is built really boosts how well it works, making sure nails come out just right every time while keeping quality steady throughout production runs. What sets it apart is automation handling so many steps automatically, which cuts down on wait times and practically eliminates mistakes people might make manually. Factories that have added these machines report getting through their orders much faster without compromising on standards. For businesses serious about staying competitive in the fast paced manufacturing world, investing in such technology pays off handsomely over time.

FAQ

What is Ky Nailing Equipment?

Ky Nailing Equipment refers to specialized tools used in construction and woodworking for driving nails precisely and securely into various materials.

Why is maintenance important for Ky Nailing Equipment?

Maintenance is crucial for ensuring the longevity and efficiency of Ky Nailing Equipment. Proper upkeep prevents rapid deterioration, equipment breakdowns, and costly repairs.

What are common issues with Ky Nailing Equipment?

Common issues include jamming, inconsistent nail depth, and air leaks. These can affect operational efficiency and should be addressed promptly.

What products enhance the performance of Ky Nailing Equipment?

The Auto Pneumatic Brad Nail Making Machine is significant for enhancing performance, offering streamlined operations and reducing manual labor in large-scale projects.

EN

EN

AR

AR

BG

BG

CS

CS

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

LT

LT

SR

SR

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

AZ

AZ

KA

KA

BN

BN

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

KK

KK

UZ

UZ