مزايا استخدام ماكينات صنع المسامير عالية السرعة في الإنتاج الضخم

تعزيز القدرات الإنتاجية باستخدام ماكينات المسامير ذات السرعة العالية

سرعة وإنتاجية غير مسبوقة في تصنيع المسامير

شهد قطاع تصنيع المسامير تغيرات كبيرة بفضل ماكينات صنع المسامير عالية السرعة التي توفر مستويات إنتاج مذهلة. تشير التقارير الصناعية إلى أن بعض النماذج قادرة على إنتاج ما يقارب 600 مسمار كل دقيقة، مما يعزز بشكل كبير من القدرات الإنتاجية. ما يجعل هذه الماكينات سريعة بهذا الشكل؟ تلعب الأتمتة دوراً كبيراً في هذا السياق، حيث تقلل من فترات التوقف وتحافظ على سير العمليات بسلاسة معظم الوقت. بالنسبة للمصنعين الذين يتعاملون مع متطلبات سوق متزايدة، فإن هذا النوع من الأداء يمثل أهمية كبيرة. تساهم التكنولوجيا الحديثة المدمجة في هذه الأنظمة في الحفاظ على أوقات الدورة ثابتة، وهو ما يؤثر بشكل مباشر على مدى إنتاجية المصنع. الشركات التي تعتمد هذه التكنولوجيا تحصل على تفوّق واضح في الحفاظ على قدرتها التنافسية مع الوفاء في الوقت نفسه بالمواعيد المطلوبة من العملاء وبشكل منتظم عبر مختلف خطوط الإنتاج.

يشمل قطاع المسامير كل شيء بدءًا من بناء المنازل ووصولاً إلى صناعة الأثاث المخصص، لذا يحتاج المصنعون الذين يرغبون في الحفاظ على قدرتهم التنافسية إلى معدات إنتاج مسامير سريعة. تقلل ماكينات تصنيع المسامير عالية السرعة من العمل اليدوي مع الحفاظ على جودة موحدة عبر الدفعات. كما أنها تساعد أيضًا على تقليل تكاليف الرواتب نظرًا لحاجتها إلى عدد أقل من العمال للتشغيل مقارنة بالطرق التقليدية. بالنسبة للشركات التي تسعى إلى النمو، فإن شراء إحدى هذه الماكينات تعني في كثير من الأحيان الفرق بين المعاناة من أجل الوفاء بالطلبات والتسليم المستمر لما يريده العملاء. وقد أخبرني مؤخرًا صاحب متجر أدوات محلية عن كيفية تمكن متجره من مضاعفة الإنتاج بعد تركيب ماكينة مسامير جديدة في العام الماضي.

الهندسة الدقيقة لتحقيق جودة مستدامة

ما يميز ماكينات صنع المسامير عالية السرعة هو تصميمها الهندسي الدقيق الذي يضمن أن تفي كل مسمار بالمعايير الصارمة للجودة. تحتوي هذه الماكينات على أنظمة متطورة لفحص الجودة مدمجة داخليًا، والتي تكتشف أي عيوب أثناء عملية الإنتاج، مما يمنع مرور المنتجات المعيبة. هذا يؤدي إلى زيادة موثوقية المنتج النهائي. عندما يستثمر المصنعون في أنظمة من هذا النوع، فإنهم يحصلون على مسامير تتميز بجودة ثابتة باستمرار من دفعة إلى أخرى. وباختصار، يُقدّر العملاء هذا الأمر، لأن عددًا أقل من المنتجات المعيبة يعني عددًا أقل من عمليات الإرجاع وعملاء أكثر رضا على المدى الطويل.

إن التكنولوجيا الدقيقة المُدمَجة في هذه الآلات تلعب دوراً أساسياً في الحفاظ على اتساق أحجام المسامير بشكل موحد. بدون هذا المستوى من الدقة، سيواجه المصنعون صعوبات في إنتاج مسامير تتناسب فعلياً مع متطلبات القطاع ومع توقعات العملاء من مشترياتهم في متاجر المعدات. لا تقوم آلة إنتاج المسامير الجيدة بتسريع العملية فحسب، بل تضمن أيضاً أن كل مسمار يخرج من خط الإنتاج يفي باستمرار بمعايير الجودة المطلوبة. وللشركات التي تسعى لبناء الثقة والحفاظ على سمعة راسخة في السوق، فإن الاستثمار في آلات مصممة بهندسة دقيقة لا يُعدّ مجرد خيار ذكي من الناحية التجارية، بل ضرورة مُلِحَّة إذا أرادت الاستمرار في توريد مسامير تؤدي بشكل موثوق يوماً بعد يوم في مواقع العمل في كل مكان.

الكفاءة التكلفة في إنتاج الأظافر بالجملة

تقليل تكاليف العمالة من خلال الأتمتة

من حيث تصنيع المسامير، تؤدي الأتمتة إلى خفض تكاليف العمالة بشكل كبير. تشير التقارير الصناعية إلى أن المدخرات قد تصل إلى نحو 30٪ عند انتقال المصانع إلى أنظمة مُؤتمتة. تأخذ الآلات عالية السرعة على عاتقها معظم العمل، لذا تحتاج المصانع إلى عدد أقل بكثير من العمال في خط الإنتاج. بهذه الطريقة تصبح عملية الإنتاج أكثر سلاسة، مع الحاجة إلى تدخل يدوي أقل من قبل الموظفين. وبعيدًا عن خفض مصروفات الرواتب فقط، تؤدي هذه الآلات أيضًا إلى تقليل الإنفاق على مدفوعات العمل الإضافي وجلسات التدريب المستمرة للموظفين. بالنسبة للشركات التي تحاول تعزيز هوامش ربحها، فإن الاهتمام الجدي بتجهيزات تصنيع المسامير الحديثة يُعد قرارًا ماليًا منطقيًا. لقد وجدت العديد من شركات التصنيع أن ترقية المعدات الخاصة بهم تعطي عوائد مالية وتحسينات في سير العمل بشكل سريع نسبيًا.

تحسين المواد وتقليل الهدر

إن معدات إنتاج المسامير الحديثة تقلل بشكل كبير من هدر المواد، مما يجعل عملية التصنيع أكثر استدامة بشكل عام. أصبحت معظم المصانع الآن مجهزة بأنظمة لجمع بقايا المعادن وصهرها مجددًا لإعادة استخدامها. هذا يعني أن كميات أقل من المواد الخام تذهب إلى مكبات النفايات، وأن الشركات تستفيد أكثر من الموارد التي تمتلكها بالفعل. كما تعتمد الآلات نفسها تقنيات قطع متقدمة تكاد لا تهدر شيئًا أثناء عمليات الإنتاج. أما بالنسبة للمصنعين الذين يسعون إلى خفض التكاليف دون التفريط في الجودة، فإن هذه التحسينات تمثل حالة مربحة للجميع. ومع ازدياد اهتمام المستهلكين بالتأثير البيئي، فإن الشركات التي تتبنى مثل هذه الممارسات تميل إلى التميز في السوق ببساطة لأنها تفعل الأشياء بطريقة مختلفة عن المنافسين الذين لا يزالون ينتجون كميات هائلة من النفايات.

الميزات التكنولوجية المتقدمة لمتطلبات صناعية

أنظمة تحكم PLC لإنتاج قابل للتخصيص

في عالم تصنيع المسامير اليوم، تلعب وحدات التحكم المنطقية القابلة للبرمجة (PLCs) دوراً كبيراً لأنها توفر للمصانع القدرة على تعديل عملياتها بناءً على احتياجات العملاء. الحقيقة هي أن هذه الأنظمة المتقدمة للتحكم تتيح للمصنّعين تغيير طريقة إنتاج المسامير بسهولة كبيرة، والتحول من تصميم إلى آخر دون أن تُفقد الكثير من الوقت على خط الإنتاج. عندما يحدث تغيّر مفاجئ في متطلبات العملاء أو في ظروف السوق، يعني وجود وحدات التحكم المنطقية القابلة للبرمجة أن المصانع قادرة على الاستجابة بشكل أسرع دون حدوث اضطرابات كبيرة. بالنسبة للشركات التي تحاول البقاء في الصدارة في هذه الصناعة السريعة الحركة، تصبح القدرة على التعامل مع الطلبات المخصصة ميزة كبيرة. ولهذا السبب، يواصل العديد من الشركات في القطاع البحث عن معدات لصناعة المسامير مزودة بتقنية وحدات التحكم المنطقية القابلة للبرمجة مدمجة فيها. في النهاية، لا أحد يرغب في البقاء عالقاً في إنتاج المقاسات القياسية بينما يقدّم الجميع تصاميم خاصة هذه الأيام.

تصاميم القوالب المستدامة ونظم التشحيم

ما الذي يجعل آلات إنتاج المسامير عالية السرعة فعالة إلى هذا الحد؟ يعود الكثير إلى جودة تصنيعها، وخصوصاً متانة قوالبها وجودة أنظمة التزييت الخاصة بها. فتصميم القوالب الجيد يعني أن هذه الآلات تدوم لفترة أطول قبل أن تحتاج إلى إصلاح، مما يقلل من فواتير الصيانة الباهظة ويضمن استمرار الإنتاج دون انقطاع. فالقوالب القوية تتحمل الضغط المستمر خلال دورات التصنيع السريعة. وفي الوقت نفسه، تضمن أنظمة التزييت الذكية حركة سلسة لجميع الأجزاء من خلال تقليل نقاط الاحتكاك الناتجة عن تدليك الأجزاء ببعضها البعض بشكل مفرط. وعندما يعمل هذان العنصران معًا بشكل صحيح، يقل الوقت الذي يُقضى في إصلاح الأعطال، كما يمكن للمصانع زيادة سرعة إنتاج المسامير. بالنسبة للشركات التي تتلقى طلبات كبيرة من مواقع البناء أو متاجر المعدات، فإن هذا النوع من الإعداد له أهمية كبيرة. فمن دون قوالب موثوقة وأنظمة تزييت فعالة، يصبح من شبه المستحيل مواكبة متطلبات الكمية في السوق التنافسية اليوم.

أفضل آلات صنع المسامير ذات السرعة العالية للبيع

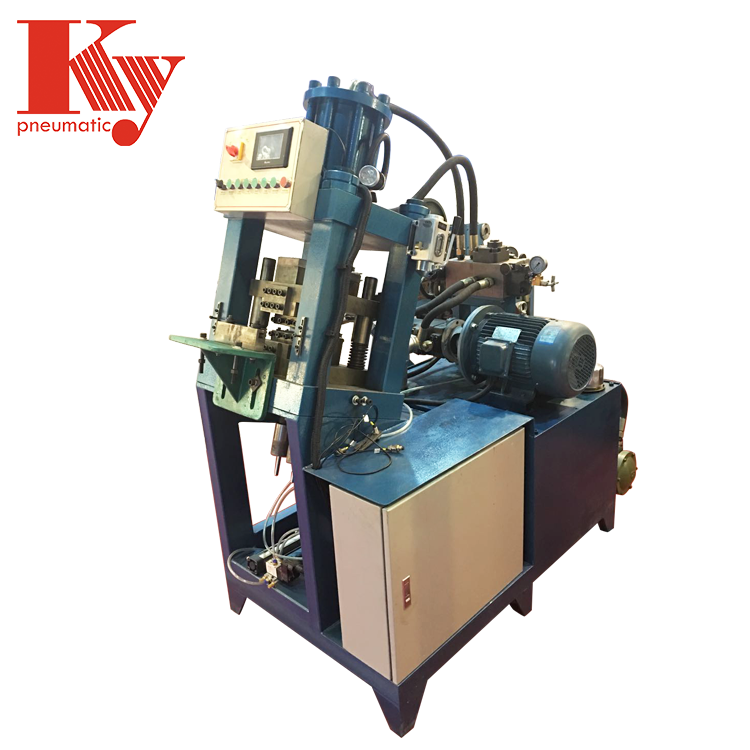

جهاز T Brad Nail Machine: مرونة حلول ثنائية

ما الذي يجعل آلة المسامير T Brad خاصةً إلى هذا الحد؟ لقد جعلتها مرونتها المزدوجة خيارًا مثاليًا للعديد من الشركات المصنعة التي تحتاج إلى تنوع في إنتاج المسامير. تكمن الميزة الحقيقية في القدرة على التبديل بين أحجام مختلفة من المسامير دون عناء يذكر. وهذا يقلل من أوقات الإعداد المحبطة عند تغيير الإعدادات. بالنسبة للشركات التي ترغب في تقديم منتجات أكثر دون التأثير على سلاسة العمليات، فإن هذه الآلة تحقق التوازن الأمثل. فقط تخيل إمكانات النمو التجاري التي تفتحها إمكانية إنتاج أحجام متعددة مع الحفاظ على سرعات إنتاج جيدة.

ماكينة مسمار F Brad: إنتاج سريع للأحجام الدقيقة

تتميز ماكينة المسامير F Brad حقًا بإنتاجها مسامير رفيعة جدًا بسرعة كبيرة. لا يمكن لهذه الأسواق التي تحتاج إلى مقاسات دقيقة ونهايات عالية الجودة أن تستغني عنها في يومنا هذا. ما يميز هذه الماكينة هو قدرتها على العمل بسرعة جنونية مع الحفاظ على معايير جودة المسامير. وقد لاحظ المصنعون زيادة في الطلب على هذه المنتجات ذات المقاس الدقيق في مجالات البناء والتطبيقات المتخصصة. ولأصحاب الورش الراغبين في توسيع نطاق إمكانياتهم، فإن الاستثمار في إحدى هذه الماكينات يُعد قرارًا اقتصاديًا منطقيًا نظرًا للتوجهات الحالية في السوق نحو المثبتات ذات الجودة العالية.

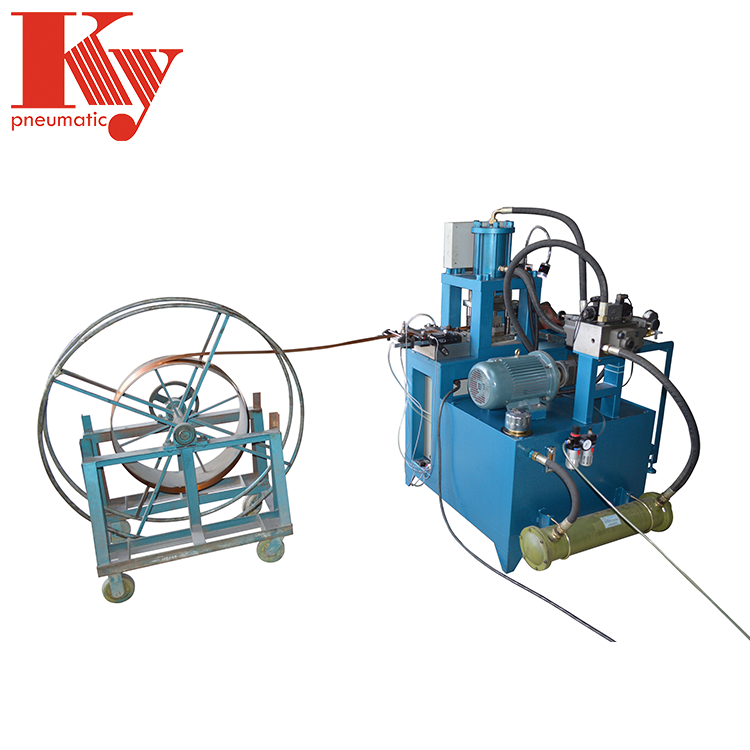

آلة البراد الهوائية الأوتوماتيكية: كفاءة التشغيل المزدوج

تجمع آلة الدباسة الهوائية الأوتوماتيكية بين القوة الهوائية والمكونات الميكانيكية لتؤدي ضعف العمل في نصف الوقت. وهي مثالية للactories التي تنتج آلاف الدبابيس يوميًا، حيث يعني هذا التكوين أن المشغلين لا يحتاجون إلى مراقبة العملية باستمرار، وهو ما يُعد تقدمًا كبيرًا مقارنة بالإصدارات الأقدم التي كانت تتطلب مراقبة مستمرة. يروي مديرو المصانع في جميع أنحاء البلاد قصصًا مماثلة في الوقت الحالي حول تحسن في المكاسب المالية بعد الانتقال إلى هذا النظام. ذكرت بعض المصانع أنها خفضت التكاليف الشهرية التشغيلية بنسبة تصل إلى 30٪ فقط لأنها أصبحت تنتج المزيد من الدبابيس دون إنفاق إضافي على العمالة أو المواد.

ماكينة سلسلة T/F: مرونة متعددة المقاييس

تعمل آلة سلسلة T/F على جميع أنواع أحجام المسامير، من المسامير السلكية الرفيعة إلى الدبابيس الثقيلة المستخدمة في البناء، مما يعني أنها تعمل بكفاءة في أسواق متنوعة. ما يميزها حقاً هو سهولة تعديل الإعدادات بين المهام. حيث يسمح بضع دقائق من ضبط المعايير بتحويل الآلة من نوع مسمار إلى آخر مع الحفاظ على سير الإنتاج بسلاسة. بالنسبة للمصنعين الذين يتعاملون مع طلبات متغيرة وطلب غير متوقع، فإن هذه المرونة تعطيهم ميزة تنافسية. يمكن للشركات الاستجابة بشكل أسرع لطلبات العملاء دون الحاجة إلى الاستثمار في عدة آلات متخصصة، وهو أمر يكتسب أهمية متزايدة في ظل التغيرات المستمرة في ظروف السوق هذه الأيام.

EN

EN

AR

AR

BG

BG

CS

CS

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

LT

LT

SR

SR

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

AZ

AZ

KA

KA

BN

BN

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

KK

KK

UZ

UZ