Základní údržbové tipy pro dlouhodobý výkon strojů na špendlíky

Základní údržbní postupy pro stroje na kličky

Libušní protokoly pro pohyblivé součásti

Dobré mazání základních strojů je skutečně prodlužuje životnost. Většina obsluh dodržuje pravidelný režim mazání, obvykle zhruba jednou za sto hodin provozu, kdy se začnou projevovat opotřebení způsobená neustálým pohybem. Výběr správného maziva je stejně důležitý. Musí fungovat v rozsahu teplot, kterým je stroj během provozu vystaven, a musí být kompatibilní s kovy použitými při výrobě. Stroje vybavené automatickými mazacími systémy mají tendenci lepšího výkonu, protože eliminují chyby, které mohou lidé při ručním nanášení maziva udělat. Důsledné dodržování plánu údržby znamená méně poruch a nižší náklady na opravy v budoucnu.

Techniky odstraňování špíny a čištění

Udržování základních strojů v optimálním stavu vyžaduje pravidelné čištění, což jsem se naučil během let praxe. Můj postup zahrnuje denní úklid zaměřený na ty otravné kovové třísky, nahromaděný prach a cokoli dalšího, co se dostane dovnitř do stroje. V průběhu času mohou tyto částice vážně ovlivnit správnou funkci stroje. Při výběru čistících prostředků je důležitá opatrnost, protože některé chemikálie mohou poškozovat určité části stroje, zejména v místech citlivých komponent. Pro odstranění zubornatělého odpadu nenajdete nic lepšího než tradiční plechovky se stlačeným vzduchem nebo průmyslové vysavače. Zjistili jsme, že tyto metody výborně dosahují do každého kouta a škvíry, kde se špína ráda ukrývá, a zajišťují, aby našeho vybavení zůstalo volné od jakéhokoli nánosu, který by mohl způsobit potíže v budoucnu.

Strategie péče o hydraulický systém

Hydraulické systémy hrají hlavní roli v tom, jak fungují stroje na výrobu hřebíků, takže pravidelné sledování těchto systémů zásadním způsobem přispívá k udržení dobrého výkonu a předchází poruchám. Pravidelná kontrola hladiny kapaliny udržuje hladký chod a zabraňuje problémům, které mohou nastat při nedostatku kapaliny v systému. Včasné vyměňování hydraulických filtrů je rovněž velmi důležité – buď podle pokynů výrobce, nebo pokud tlak začne projevovat nepravidelnosti – pomáhá udržet systém bez ucpaní a efektivně fungující. Nezapomeňte také kontrolovat hadice a připojení na případné známky úniků, protože zanedbání menších problémů na tomto místě se často promění v závažné potíže v budoucnu. Rychlá oprava těchto problémů zajistí delší životnost hřebíkovače a jeho spolehlivý provoz v průběhu času. Kvalitní zvyklosti údržby hydraulického systému skutečně zvyšují jak kvalitu, tak výstup výroby hřebíků.

Plánované inspekční rutiny

Zavedení pravidelných kontrolních rutin značně pomáhá udržovat základní stroje v optimálním provozním stavu. Většina dílen zjistí, že kontrola zařízení jednou za týden nebo dva týdny je dostatečná k tomu, aby byly včas zachyceny první známky opotřebení, než se stanou větším problémem. Při těchto kontrolách si zapisujte všechny informace, od drobných škrábanců po neobvyklé zvuky, které stroj vydává. Kvalitní záznamy se v budoucnu stávají velmi cennými, protože se začnou objevovat vzorce v degradaci různých komponent v průběhu času. A také nezapomeňte mít pro každou kontrolu kontrolní seznam. Spolehlivý kontrolní seznam připomene technikům, že mají zkontrolovat bezpečnostní prvky, jako jsou nouzové zastavení, a také prověřit klíčové výkonnostní parametry všech hlavních komponent. Tento jednoduchý krok výrazně snižuje pravděpodobnost, že během běžných údržeb někdo něco důležitého přehlédne.

Analýza vzorů poškození pro nahrazování dílů

Sledování toho, jak se díly opotřebovávají v průběhu času, pomáhá zjistit, jak dlouho budou komponenty v základních strojích trvat, než je bude třeba vyměnit. Když provádíme tento druh analýzy, stává se zřejmým, které díly se opotřebovávají rychleji než jiné, takže plány údržby lze přizpůsobit skutečnostem na výrobní lince. Vizuální kontrola spolu s použitím vhodných měřicích nástrojů zásadně ovlivňuje zjišťování neobvyklých vzorů opotřebení, které mohou naznačovat větší problémy skryté uvnitř strojů. Také je velmi důležité dodržovat pokyny výrobců ohledně známek opotřebení pro každý konkrétní model stroje. Jejich doporučení nám dávají dobrou představu o normální míře opotřebení jednotlivých dílů, což umožňuje technikům včas vyměnit ohrožené komponenty dříve, než by mohly způsobit větší poruchy během výrobních cyklů.

Řízení vlhkosti v elektrických systémech

Udržování vlhkosti mimo elektrické systémy je velmi důležité, aby se předešlo zkratům a problémům s vybavením, zejména v prostředích s vysokou vlhkostí. Instalace věcí jako jsou silikagelové vložky nebo vhodné systémy pro kontrolu vlhkosti pomáhají zajistit hladký chod a chrání citlivé elektrické komponenty před poškozením. Pravidelné kontrolování elektrických rozvaděčů a připojení na známky rezavění nebo pronikání vody by nemělo být omezeno pouze na občasné kontroly. Každý, kdo pracuje s elektrickými systémy, ví, že tato témata vyžadují neustálou pozornost. Rychlé řešení problémů s vlhkostí prodlužuje životnost vybavení a snižuje riziko významných elektrických poruch, které mohou způsobit úplné výpadky provozu. To znamená, že stroje zůstávají spolehlivě v provozu den po dni bez neočekávaných výpadků.

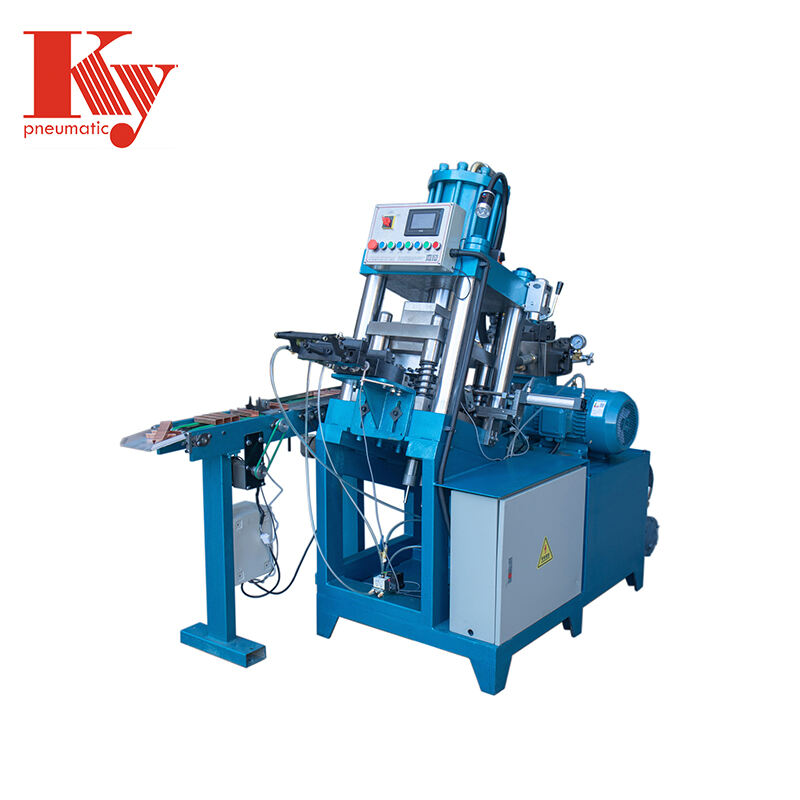

Hydraulický kartonážní stehací systém s automatickým maštováním

Automatické mazací systémy skutečně pomáhají prodloužit životnost hydraulických systémů hřebínků, protože snižují tření a opotřebení v průběhu času. To, co tyto systémy činí tak cennými, je jejich schopnost pravidelně aplikovat mazivo bez nutnosti, aby je někdo neustále kontroloval nebo ručně doplňoval. To znamená méně prostojů kvůli údržbě a lepší celkový výkon strojů. Když firmy instalují tohoto typu systémy, obsluha obvykle zjistí, že jejich zařízení běží hladčeji po delší dobu mezi servisními prohlídkami. Zmenšená frekvence údržby se překládá do úspor nákladů a méně výpadků výroby v prostředích, kde každá minuta má význam.

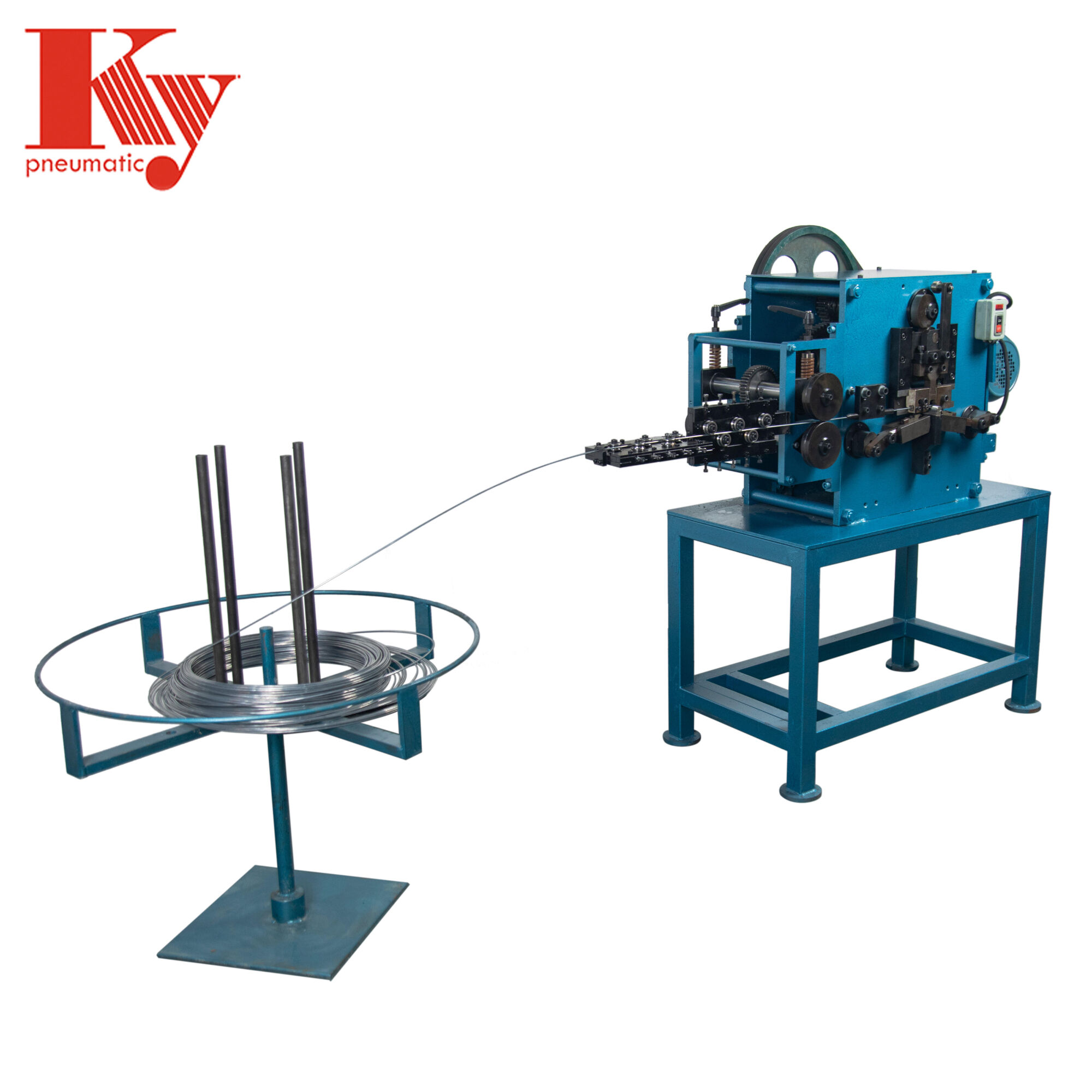

Jednotka na výrobu C-koleček s přesným zarovnáním

Přesné zarovnání v jednotkách pro výrobu C-kroužku výrazně snižuje opotřebení a tím zvyšuje trvanlivost a konzistenci kvality produktu. Například strojní zařízení s funkcí přesného zarovnání dokázalo zlepšit provozní efektivitu udržováním přesných výrobních procesů a snížením potřeby častých úprav.

Vysokorychlostní karbonově ocelový špendlíkový tlač s PLC monitorováním

PLC monitorování hraje klíčovou roli ve vysokorychlostních tlačích pro karbonově ocelové špendlíky, nabízí reálně časové diagnostiky pro podporu preventivní údržby. Pomocí pokročilého monitorování mohou výrobci předpovídat a řešit potenciální problémy, což významně snižuje simply a udržuje kontinuitu výroby.

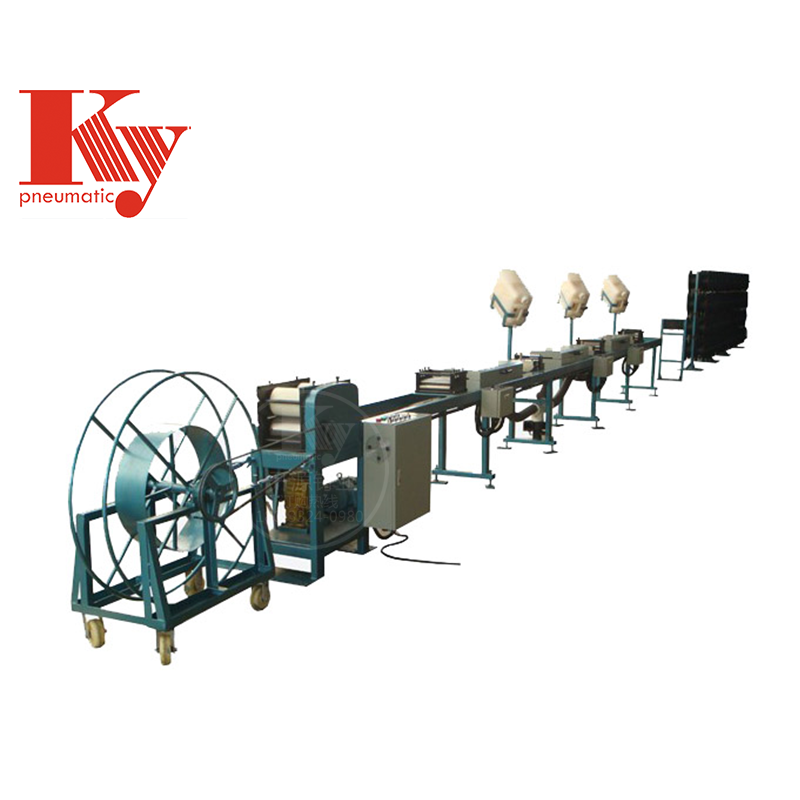

Stroj na výrobu drátových pásů s plnohodnotnou samo-diagnostikou

Samodiagnostické funkce jsou v pásových strojích zásadní, protože upozorňují obsluhu na potřebu údržby a zabrání tomu, aby menší problémy eskalovaly na kritické. Tato technologie výrazně snižuje prostoj a zvyšuje efektivitu – studie ukazují, že takové inovace mohou zlepšit provozní efektivitu až o 70 %.

Servo-pohonový robustní výrobek střepů

Systémy poháněné servopohony nabízejí významné výhody při výrobě těžkostrojových střepů, poskytují zvýšenou energetickou účinnost a přesnost. Odborníci na průmysl uznávají, že technologie servopohonu umožňuje lepší provozní efektivitu, poskytuje hladké a přesné pohyby pro konzistentní kvalitu produktu.

Diagnostické nástroje pro prediktivní údržbu

Analýza vibrací pro stav ložisek

Analýza vibrací se řadí mezi nejlepší způsoby, jak včas odhalit potenciální problémy s ložisky, než způsobí vážné potíže s provozem strojů. Když technici měří, jak se zařízení během provozu třese, mohou subtilní změny často odhalit první známky opotřebení nebo poškození ložisek již týdny či měsíce před vlastní poruchou. Výhodou tohoto přístupu není pouze předcházení neočekávaným výpadkům, ale také prodloužení doby mezi výměnami strojů. Většina odvětví nyní sleduje směrnice nastavené organizacemi, jako je ISO, při plánování svých údržbových programů. Tyto normy uznávají, že pravidelné kontroly vibrací přinášejí skutečné úspory nákladů, a to jak na nákladech způsobených neplánovanými zastávkami, tak i na nákladných opravách, které vyplývají z náhlých poruch.

Termální imagina pro hodnocení obvodů

Termální zobrazování se řadí mezi nejlepší způsoby, jak včas odhalit komponenty, které v elektrických obvodech příliš zahřívají, než by způsobily větší problémy. Když se podíváme na obvody pomocí termální kamery, vidíme, kde se abnormálně hromadí teplo, a to nám přímo ukazuje problematická místa, aniž bychom museli věci rozebírat. Podle výzkumu publikovaného v časopise Elektroinženýrství snížila jedna továrna své elektrické poruchy téměř o třetinu poté, co zavedila pravidelné termální kontroly ve všech procesech. Možnost včasného odhalení těchto problémů znamená méně neočekávaných výpadků a bezpečnější pracovní podmínky pro všechny, kdo denně pracují s elektrickými systémy.

Integrace automatizovaných upozornění

Přidání automatických systémů upozorňování do provozu údržby zásadně mění způsob, jakým jsou zaměstnanci informováni o aktuálních úkolech údržby. Tyto systémy umožňují personálu závodu rychle reagovat na problémy, čímž se zkracuje doba reakce a prodlužuje doba mezi poruchami zařízení. Kombinace dat v reálném čase a inteligentní analýzy pomáhá včas identifikovat potenciální problémová místa, než se drobné závady promění v rozsáhlé potíže. Nedávný článek z Maintenance Technology přinesl několik praktických výsledků, kdy podniky po instalaci těchto systémů upozorňování zaznamenaly zhruba o 40 % méně neočekávaných výpadků, což jasně ukazuje, jak cenné jsou tyto systémy pro plánování údržby v režimu prevence. Pokud mají týmy provádějící údržbu přístup k těmto upozorněním, opravy se prostě vyřeší rychleji a zařízení se dříve vrátí do provozu, což znamená lepší výrobní výkony v celém závodě.

EN

EN

AR

AR

BG

BG

CS

CS

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

LT

LT

SR

SR

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

AZ

AZ

KA

KA

BN

BN

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

KK

KK

UZ

UZ