Didžiuojantis poročių mašinų taikymas įvairiose pramonėse

Pagrindinės pramonės šakos, naudojančios kiaulinių ženklų mašinas

Agrarinis sektorius: kandžių gamyba ir augalų palaikymas

Kiaulių žiedų mašinos tapo būtina įmone, dirbančia žemės ūkyje, daugiausia naudojama gyvūnų narvams kurti ir augalų atraminiams konstrukcijoms. Tai, kas išskiria šias mašinas, yra tai, kaip greitai jos tvirtai sujungia laidus, todėl bet ką, kas yra pastatyta, laikoma stipriai ir nereikia nuolat taisymo ateityje. Ilgainiui ūkininkai sutaupo pinigų, nes šios konstrukcijos trunka ilgiau nei alternatyvos. Kai augalai gauna tinkamą kiaulių žiedų atramą, derlius būna geresnis. Galvijai taip pat lieka ten, kur turi būti, nes aptvaros išlaiko slėgį. Daugeliui ūkių tokia patikimumo rūšis reiškia mažiau rūpesčių per užimtumo sezonus, kai kiekviena minutė skaičiuojama.

Produkto pavadinimas: Agrarinė kiaulinių ženklų mašina

Automobilių pramonė: sedeilių montavimas ir tapetė

Kiaulės žiedo mašinos svarbiai prisideda prie automobilių pramonės, ypač kuriant automobilio sėdynes ir vidinius komponentus, kur ypač svarbu stiprumas. Šios įrangos siūlo greitus ir patikimus tvirtinimo sprendimus, kurie leidžia montavimo linijoms veikti sklandžiai, be pertraukimų. Gamtoje dirbantys darbuotojai iš patirties žino, kad kiaulės žiedo technologijų naudojimas dažnai reiškia mažiau darbo valandų, praleistų rankiniam tvirtinimui, tuo tarpu padidėja gamybos našumas. Todėl pagrindiniai automobilių gamintojai jau dešimtmečius naudojasi šia įranga sėdynių gamybos procesuose ir įvairiose apmušimo operacijose automobilių gamyklų viduje.

Gaminimo įranga: rankšlyjų ir kanapės gamyba

Šiandien baldų gamyboje svarbų vaidmenį vaidina kiaulių žiedų mašinos, ypač gaminant čiužinius ir sofas. Jų vertę nulemia patikimas medžiagų tvirtinimas, kuris suteikia baldams geresnį konstrukciją bei ilgaamžiškumą. Pramonės duomenys rodo, kad gamykloms, naudojančioms kiaulių žiedų technologiją, pavyksta padidinti gamybos greitį apie 30 % lyginant su senesnėmis metodais. Įmonės taip pat pastebi realių privalumų – greitesnė gamyba leidžia pagaminti daugiau vienetų, tuo pačiu mažėjant darbo jėgos kaštams. Būtent todėl daugybė įmonių baldų sektoriuje pastaruoju metu pradėjo naudoti kiaulių žiedus savo gamybos procesuose.

Statybinės programos: Gabion krepšiai ir drabužio tinklelis

Kiaulės žiedų mašinos yra labai svarbios statybos darbuose, ypač kai kuriamos konstrukcijos, reikalaujančios papildomos armatūros. Šios mašinos padeda gaminti gabionų krepšius ir vielos tinklelius, kuriais remiasi inžineriniai projektai. Patys gabionai yra akmenų pripildyti kiaurėti kiaušai, kurie laiko laikomąsias sienas ir neleidžia dirvožemiui nusiplauti palei upių krantus. Kodėl kiaulės žiedai atliedami savo darbą yra tokie geri? Na, jų tvirtinimo būdas leidžia sukurti labai patikimą ir ilgaamžę konstrukciją. Tokia stiprumo savybė yra labai svarbi, nes daugelyje inžinerinių projektų priklauso nuo stabilios bazės. Laikomosios sienos ypač reikalingos tokios paramos, kadangi jos nuolat priešinasi žemės slėgiui, o kartais net vandens slėgiui, veikiančiam iš po žemės lygio.

Technologinių pokytų stabių jungiklių mašinoje

Tikslus automatizavimas aukštojo apimties gamybai

Naujausios pažangos kiaulių žiedų mašinose dabar siūlo tikslų automatizavimą, kuris tikrai padidina šių mašinų gamybos galimybes, kai jos veikia didelėmis apimtimis. Gamintojams, kurie kasdien pasikliauja kiaulių žiedų mašinomis, tai reiškia tikrą perėjimą prie naujo operacijų vykdymo būdo. Šie nauji automatizuoti įrenginiai veikia daug greičiau nei anksčiau, neprarandant kokybės, o tai gamyklų vadovai pastebi iš karto, kai užsakymai pradeda klostytis greičiau. Pagal pramonės ataskaitas, perėjus į automatizavimą, įmonės paprastai pasiekia apie 50 % gamybos rodiklių šuolį lyginant su tradiciniais metodais. Skirtumas pasireiškia ne tik kiekybėje, bet ir skirtingų produktų linijų vientisume.

Funkcijos daugiamačio suderinamumo

Šių dienų kiaulių žiedų mašinos yra įrengtos savybėmis, leidžiančiomis jiems apdoroti įvairias medžiagas, o tai yra gana patogu, kai gamybos poreikiai kasdien kinta. Galimybė perjungti tarp medžiagų reiškia, kad gamykloms nereikia atskirų mašinų kiekvienai medžiagos rūšiai, sumažinant išlaidas ir išlaisvinant vertingą plotą gamybos patalpose. Pramonės specialistai pažymi, kad tokia įvairovė suteikia gamintojams daugiau laisvės operacijoms. Jie gali pasirinkti iš platesnio medžiagų diapazono, nesumažindami darbo kokybės ar galutinio produkto kokybės. Kai kurios gamyklų praneša galėdavusios prisiimti naujus kontraktus, kurių anksčiau negalėjo įgyvendinti dėl šių patobulintų savybių.

Energinis efektyvumas ir žemas triukšmas

Vis daugiau gamyklų šiais laikais linksta prie energiją taupančių varžtavimo mašinų, nes žalioji gamyba tapo svarbiausiu prioritetu daugelyje sektorių. Kodėl šios mašinos yra tokios patrauklios? Jos sumažina elektros suvartojimą ir darbo vietų triukšmą, todėl darbuotojams nebereikia kentėti nuolatinio garsaus triukšmo. Kai kurios studijos parodė, kad pereinant prie šių efektyvių sistemų įmonės gali sutaupyti apie 20 procentų eksploatacinių kaštų, neprarandant gamybos kokybės. Gamintojams, siekiantiems sumažinti anglies pėdsaką, neperkant brangiai, investicijos į energiją taupančią varžtavimo technologiją nėra tik protingas verslas – ji jau tampa kone standartine praktika šiandieninėje ekologiškai sąmoningoje rinkoje.

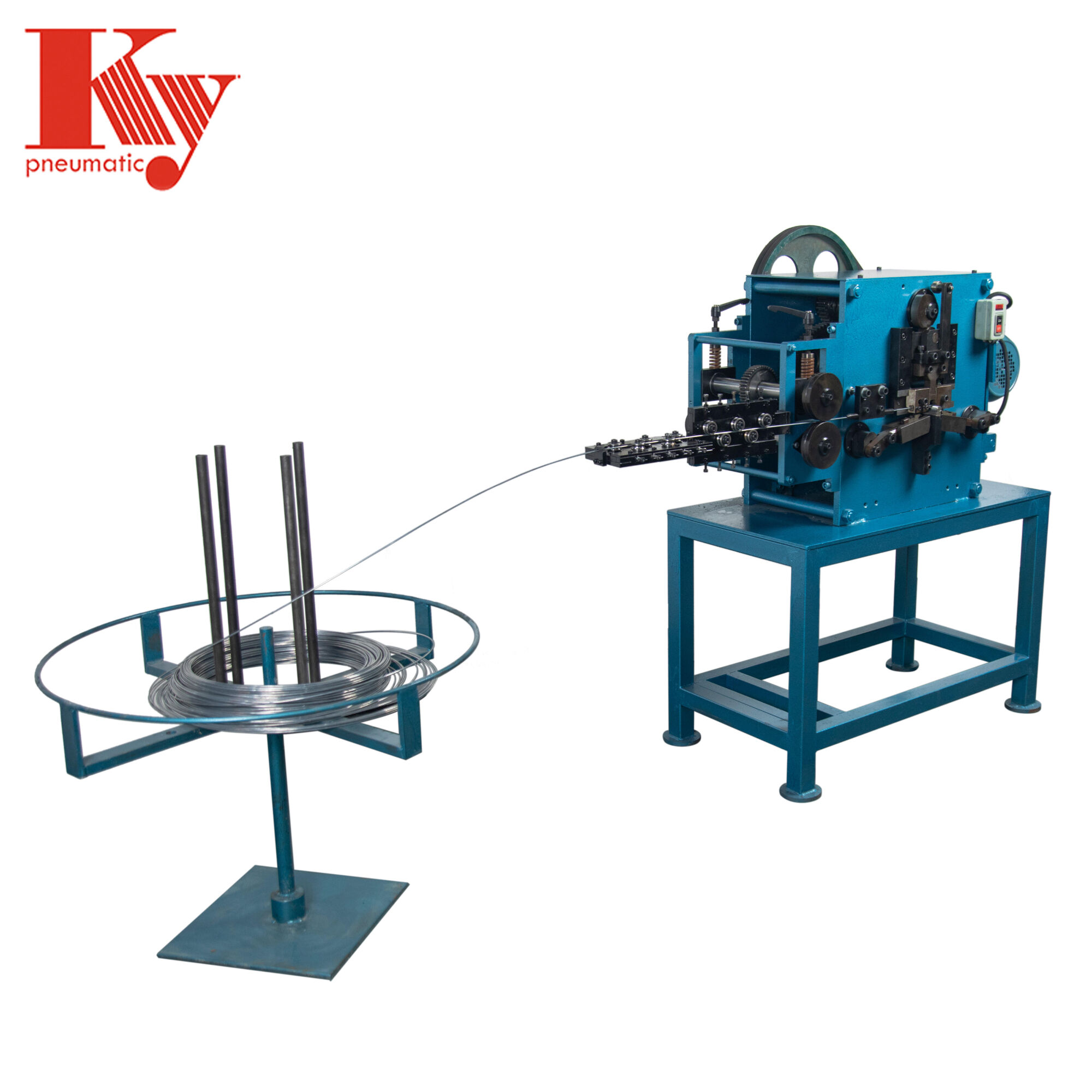

Pramoninės klasės „Hog Ring“ mašinos: produkto apžvalga

„Hog Ring“ mašina: Pilna automatizacija įvairioms programoms

Pilnai automatizuota technologija pavertė kiaulių žiedų mašinas į ištvermingas mašinas, kurios gamybos aplinkoje suteikia tikrą pranašumą. Kai operatoriai atsitraukia nuo proceso, šios mašinos nuosekliai išlaiko kokybės standartus, tuo tarpu gamybos klaidų rodikliai smarkiai mažėja. Daugelyje šiuolaikinių modelių yra integruoti skaitikliai ir tikslūs vinų pjūkliukai, kad kiekvienas pagamintas produktas atitiktų tikslų specifikaciją. Kuo jos išsiskiria? Jos gali susidoroti su viskuo – nuo vištų aptvarų tvirtinimo iki automobilių detalių surinkimo, be jokio pertraukimo adaptuodamos tarp skirtingų produktų linijų. Kuo daugiau gamyklų susiduria su mažesniais biudžetais ir mažėjančiu darbuotojų skaičiumi, tuo dažniau gamintojai pastebi, kad investicijos į automatizuotus kiaulių žiedų sistemų sprendimus ilgainiui atsiperka dėl sumažėjusio šalutinio produkto kiekio ir didesnio apdorojimo našumo.

C Ring Staple Hog Ring Making Machine: Specialybės fiksatoriaus gamyba

Kai kalbama apie specialių žiedų spaustukų gamybą, C žiedo spaustukų mašina išsiskiria. Sukonstruota greitam darbui, ši mašina lengvai susidoroja su skubiais užsakymais, išlaikydama efektyvumą. Tai, kas ją išskiria – vidinės sistemos, kurios sumažina atliekų medžiagą gamybos metu, todėl ilgainiui mažėja jos poveikis aplinkai. Mašina gali gaminti įvairių tipų tvirtinimo elementus – tokius kaip C žiedai ir D žiedai – todėl ji naudinga įvairiose pramonės šakose. Nuo baldų rinkimo iki automobilių dalių tvirtinimo, tokia įvairovė leidžia įmonėms nekeisti mašinų skirtingiems darbams. Kadangi vis daugiau įmonių linkusi pereiti prie žalesnių gamybos praktikų, tokia įranga tampa būtina, kad išliktum konkurencingas ir atitiktum šiuolaikinius atsakingumo standartus.

Hog Ring Aparatų Pasirinkimas Operacinėms Reikmėms

Vertinant Gamybos Apimties Reikalavimus

Kai kalbama apie žąsų žiedų mašinų pasirinkimą, viskas priklauso nuo to, kiek produktų per dieną reikia perdirbti įmonėje. Kai gamintojai įvertina tikrąją savo gamybos apkrovą, jie gali tinkamiau pasirinkti įrenginius, kurie atitiktų jų operacijų poreikius. Mažos dirbtuvės dažnai lieka su brangiomis sunkiosios technikos medžiagomis, kurios daugumą laiko būna neaktyvios, nes tiesiog nėra pakankamai darbo, kad pateisintų tokias išlaidas. Tačiau didelės operacijos pasakoja kitokias istorijas. Automatizuotos sistemos ilgainiui atsiperka, nes jos nuosekliai gamina dalis be pertrūkių. Pramonės duomenys nuolat rodo vieną aiškią tendenciją – įmonės, suderinančios savo mašinų galimybes su tikrąja gamybos realybe, veikia sklandžiau ir ilgainiui sutaupo daugiau lėšų.

Vertinant darbo vietos apribojimus

Renkantis kiaulių žiedų mašinas, labai svarbu įvertinti faktinę darbo vietą, nes patalpos dydis ir jau esami objektai nulemia, kurios mašinos tikrai tiks. Vėliau susidūrus su vietos stokos problema, gali sutrikti šių mašinų tarpusavyje suderinamumas ir gali sulėtėti gamyba. Dauguma šios srities specialistų rekomenduoja iš anksto tiksliai nubrėžti, kur bus kiekviena detalė, prieš įsigyjant naujų įrenginių. Jei iš pradžių viską padarysite teisingai, vėliau kils mažiau netikėtumų, diegiant įrangą. Gerai parengtas išdėstymo planas padeda užtikrinti sklandžią veiklą ir leidžia tinkamai panaudoti kiekvieną grindų plotelį, o ne švaistyti vertingą erdvę.

Pneumatinių ir elektros sistemos palyginimas

Sprendimas tarp pneumatinių ir elektrinių kiaulių žiedų sistemų iš tikrųjų priklauso nuo to, kas svarbiausia kasdieniniam darbui. Pneumatiniams modeliams reikia reguliariau prižiūrėti, tačiau jie puikiai veikia, kai greitis yra svarbiausias dalykas, todėl daugelis mėsos perdirbimo įmonių vis dar pasitiki jais, nepaisant papildomo priežiūros. Elektros alternatyvos paprastai sutaupys pinigų, nes jos yra švaresnės ir reikalauja mažiau dalių. Kai kurios pramonės ataskaitos rodo, kad perėjimas nuo vienos sistemos prie kitos gali pakeisti bendrąsias išlaidas apie 15% ar daugiau, priklausomai nuo naudojimo modelio. Įmonėms, siekiančioms subalansuoti biudžetus, nepažeidžiant našumo, labai svarbu atidžiai išnagrinėti šiuos skirtingus aspektus. Juk nėra dviejų įrenginių, kuriuose būtų tenkinti vienodi reikalavimai, susiję su įrangos pasirinkimu.

EN

EN

AR

AR

BG

BG

CS

CS

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

LT

LT

SR

SR

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

AZ

AZ

KA

KA

BN

BN

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

KK

KK

UZ

UZ