Automatic Wire Drawing Machines and Their Benefits in Continuous Production

Key Features of Modern Automatic Wire Drawing Machines

High-Speed Processing and Continuous Operation

Today's automatic wire drawing machines can run at incredibly fast speeds, sometimes going over 25 meters per minute. This means factories can churn out way more product without spending extra time waiting around. Most models are built for non-stop running too, so they don't break down as often as older versions did back in the day. And when problems do happen? They usually fix themselves pretty quick. These machines also come with smart controls that automatically change speed depending on what kind of metal is being worked on. Some shops report saving hundreds of hours each month just from having these smarter systems in place across different production lines.

Precision Engineering for Consistent Output

Modern wire drawing machines rely on precision engineering to keep outputs consistent across production runs, carefully controlling both wire diameter and tensile strength throughout the process. Manufacturers now incorporate advanced technologies like laser measurement systems that monitor dimensions in real time, helping to maintain tight tolerances while cutting down on material waste. When these machines operate within such narrow parameters, there's simply less room for defects to occur, meaning fewer batches end up needing costly rework. The result? Higher quality products that customers can trust. For industries ranging from automotive manufacturing to aerospace components, getting those wire specs exactly right isn't just important it's absolutely essential for passing rigorous industry certification requirements.

Integrated Lubrication and Cooling Systems

Modern wire drawing machines rely heavily on integrated lubrication and cooling systems to boost overall efficiency during operation. The lubrication part works by cutting down on friction between moving parts, which means less wear and tear happens over time. This actually makes the machine last longer before needing replacement parts. When it comes to cooling, these systems keep things running at just the right temperature so nothing gets too hot and starts malfunctioning. Most plant managers know that regular checkups on both systems pay off big time. Machines stay in good condition for years instead of months, and companies save money on repairs and downtime costs. For many manufacturers, this kind of maintenance routine has become standard practice across most production facilities.

Benefits in Continuous Manufacturing Environments

Minimized Production Downtime

Wire drawing machines that run automatically play a major role in cutting down on production stoppages. These machines cut back on the need for hands-on work, which makes the whole process smoother and stops those frustrating delays caused by mistakes people make or just plain old inefficiency. The smart diagnostic features built into many modern machines really boost their dependability too. They spot problems early on before something breaks completely, so maintenance crews can fix things before major breakdowns happen. Factories that switched to this kind of automation typically see their equipment running nonstop about 25% more than before. Some plants even report better results when operators learn how to work with the new technology properly over time.

Enhanced Product Uniformity Across Batches

When automated systems make adjustments during the drawing process, they help maintain consistent output quality. This matters a lot when trying to get uniform products from one batch to the next. Take nail manufacturing for instance the whole point of nails is that they work reliably, and that just doesn't happen if there's too much variation between them. Statistical quality control isn't just some abstract concept either. Real manufacturers use these methods day in and day out to spot potential problems before they become actual defects. The result? Fewer rejects and more dependable batches coming off the production line.

Scalability for High-Volume Output

Wire drawing machines today come built for scaling up production when needed, giving manufacturers real flexibility as demand goes up. When markets shift suddenly, these machines let companies adjust quickly without getting stuck waiting weeks for new equipment. Many modern systems have modular parts too, so factories can expand their capacity just by adding components rather than buying whole new machines. This saves money while still keeping up with big orders, something especially important during peak seasons or unexpected surges in customer requests.

Applications in Nail Production and Metal Fabrication

Custom Wire Preparation for Nail Manufacturing Machines

Wire drawing machines play a big role in making the right wire shapes needed across all sorts of nail production scenarios. When manufacturers can tweak how they prepare the wire, there's actually quite a bit less scrap material going to waste during manufacturing runs. These machines handle switching between different wire gauges pretty smoothly too something that matters a lot when making nails meant for different jobs around construction sites or woodworking shops. The flexibility saves money on materials while keeping production lines running faster than older methods could manage, which explains why so many factories have upgraded their equipment recently.

Multi-Stage Processing Capabilities for Complex Profiles

Modern machines with their multi stage processing abilities make it possible to create intricate wire shapes that go straight into steel nail production. When manufacturers combine several forming steps into one smooth operation, they cut down on time wasted moving materials between different machines. This approach opens up new possibilities for product designs while giving companies an advantage over competitors who still rely on older methods. For instance, some firms have started producing nails with special grooves or coatings that weren't feasible before. Handling such complex wire profiles has become essential for anyone serious about nail manufacturing today. These advanced systems simply work better and faster than traditional setups, driving both cost savings and creative breakthroughs across the industry.

KY Industrial Wire Processing Solutions

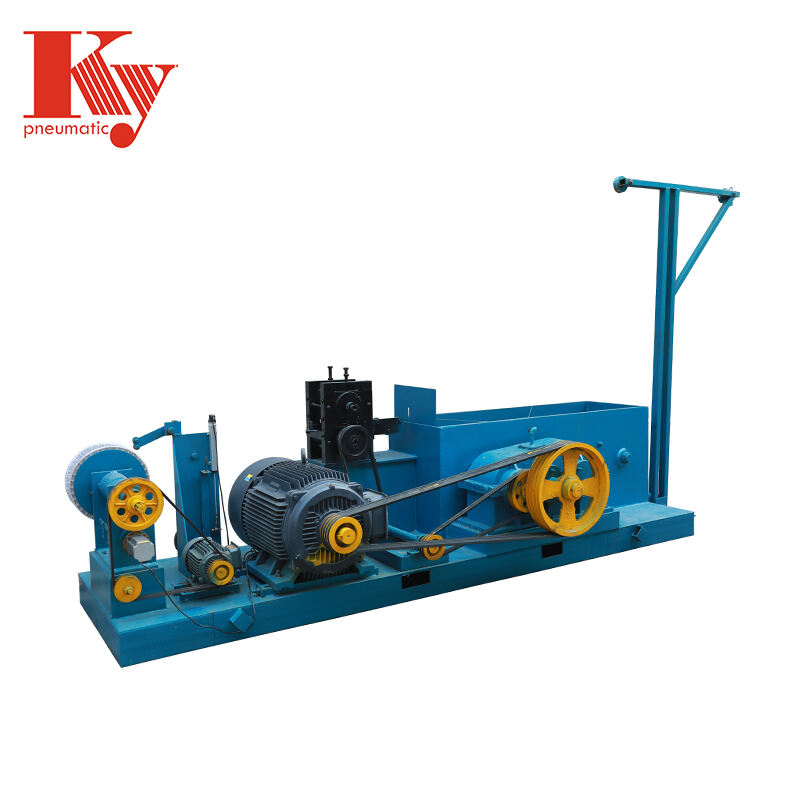

KY Pneumatic Wire Drawing and Flattening System

The KY Pneumatic Wire Drawing and Flattening System takes wire production to new levels by incorporating advanced pneumatic technology into the manufacturing process. What sets this apart is how it boosts productivity while consistently creating flat wire products needed across various industries, particularly in nail manufacturing where exact dimensions matter most. When it comes to flattening wires, this system delivers remarkable accuracy that manufacturers need for producing quality nails without defects. Another big plus? Pneumatic systems generally require less maintenance compared to traditional methods and consume significantly less energy over time. These factors combine to make the KY system an economically smart option for factories looking to cut costs without sacrificing product quality.

Fully Automated Galvanized Iron Wire Processor

KY's fully automated galvanized iron wire processor delivers impressive output rates while making sure the final products can stand up to tough conditions. The automation built into this system cuts down on labor expenses quite a bit, plus it keeps workers safer since they don't have to handle hot materials as much during processing. Manufacturers report saving thousands each month thanks to this machine's efficiency, which lets them produce more goods without having to spend extra money on staff or resources. For metal fabrication shops looking to modernize their operations, this kind of automation represents real progress in how industries approach production challenges today.

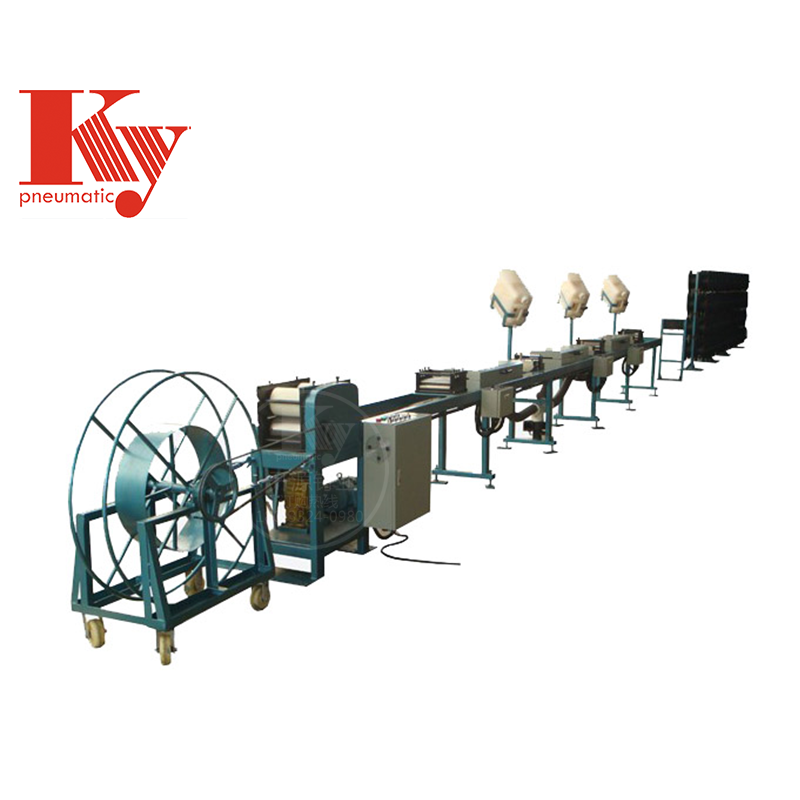

Complete Staple Production Line Integration

When KY wire processing solutions get incorporated into staple production lines, they really boost how well things run day to day. These systems cut down on the time workers spend handling materials and actually making staples, so everything moves along much smoother than before. The company saves money too because there's less need to hold onto excess inventory while still keeping products moving through the factory without interruption. For manufacturers trying to keep up with demand, this kind of setup makes all the difference. KY's approach shows just how much better manufacturing can become when companies invest in smarter processing methods. Their systems aren't just about saving time though they also help businesses stay ahead of competitors who haven't made similar upgrades to their operations.

EN

EN

AR

AR

BG

BG

CS

CS

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

LT

LT

SR

SR

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

AZ

AZ

KA

KA

BN

BN

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

KK

KK

UZ

UZ