Key Attributes of a Reliable Wire Drawing Machine Manufacturer

Technical Expertise and Industry Experience

Years of Specialization in Wire Drawing Technology

The company has built a solid track record over the past 40+ years working specifically with wire drawing tech, which is why most folks in the business know us as industry leaders. We've hit quite a few important markers along the way. Take our work on high speed wire drawing machines for example these actually changed how manufacturers approach their daily operations. Quality matters to us though, so when we finally rolled out the MSM86 model last year, it was something special for our customers who needed reliable performance day after day. Many manufacturers told us this machine made their production lines run smoother than ever before. We also team up regularly with top names in the sector including NIEHOFF among others. These relationships aren't just about logos on brochures they represent real collaboration where everyone benefits from shared knowledge and better outcomes across the wire drawing landscape.

Certifications and Compliance with Global Standards

Getting certified matters a lot when it comes to showing we care about quality and safety. Our company holds several important certifications like ISO 9001 and CE marks, all proof that we follow international manufacturing guidelines. These aren't just pieces of paper either they help build trust with customers who want to know their products are safe and reliable. When businesses stick to these kinds of standards, people tend to trust them more. Industry numbers back this up too some stats suggest companies following ISO standards see around a 20% improvement in market reach and international sales. To keep things running smoothly, we run regular checks on everything from production lines to finished goods. This ongoing process makes sure our equipment stays at top performance levels and keeps us respected across different markets worldwide.

Precision Engineering and Quality Control Systems

Advanced Wire Drawing Machine Components

The components of advanced wire drawing machines are really what makes them tick when it comes to getting good results from production runs. Most models come equipped with things like drawing dies, capstans, and those wire straightening units, all working together to get the job done right. We've seen some interesting changes lately where manufacturers are starting to use better materials for these parts. Tungsten carbide has become popular choice for dies because it lasts longer and doesn't wear down as fast. Some newer designs also feature electromagnetic dancer systems that help maintain just the right amount of tension during operation. A factory in Ohio recently upgraded their equipment with these improvements and saw significant gains in wire quality while cutting down on maintenance stops. This shows how important proper engineering is when building effective wire drawing systems.

Error Rate Tolerance and Performance Metrics

When it comes to wire drawing machines, understanding error rate tolerance matters a lot for anyone in the business. Basically, it's about how many mistakes can happen during the actual wire drawing without ruining what comes out at the end. Most industries stick pretty close to strict rules when setting these limits because nobody wants defective products going out the door. The best manufacturers manage to keep errors really low thanks to some serious engineering work behind the scenes. They watch things like how evenly strong the wire is throughout and whether all pieces come out exactly the same size. Some factories actually track these numbers daily against specific targets they've set themselves. Take XYZ Manufacturing for instance – after installing better quality checks last year, they cut down on errors by nearly half. That kind of improvement means faster production times and customers getting what they paid for without surprises. Looking at these real world results shows why keeping an eye on those key performance numbers remains so important in wire drawing operations.

Customization Capabilities for Diverse Applications

Adaptability to Nail Making and Staple Production Needs

Customizing manufacturing equipment to fit particular production needs makes all the difference in today's competitive market. Take nail and staple making machines for example there are plenty of ways to tweak them according to what a business actually needs. Most manufacturers offer different setups, special add-ons, and control systems that can be programmed for specific jobs. A company might want their machine modified so it can quickly change between making various nail sizes or work with certain kinds of wire stock. Sometimes it's just adjusting the wire thickness slightly, other times they need to switch completely from making nails to staples. This kind of flexibility really matters because it lets both tiny workshops and big factories keep up with whatever their customers throw at them without having to buy entirely new machinery every time requirements change.

Tailored Solutions for Medium-to-Large Scale Operations

Getting clear on what medium to large scale operations really need matters a lot when it comes to making industrial processes work better. When working with these kinds of operations, good solutions usually start with looking closely at what the client wants to produce, what kind of machines they already have, and how much room there is in their facility. After doing this kind of thorough check, manufacturers can adjust machine setups so they actually get more done faster. Many companies report great results from custom built machinery, which tends to make them happier customers overall. These made to order systems fit right into current workflows without causing disruptions. Take for example a factory line that lets workers switch from one product batch to another quickly. This cuts wasted time between runs and means more products come out each day. Most business owners who go this route find that their plants run smoother and problems that used to slow things down just disappear.

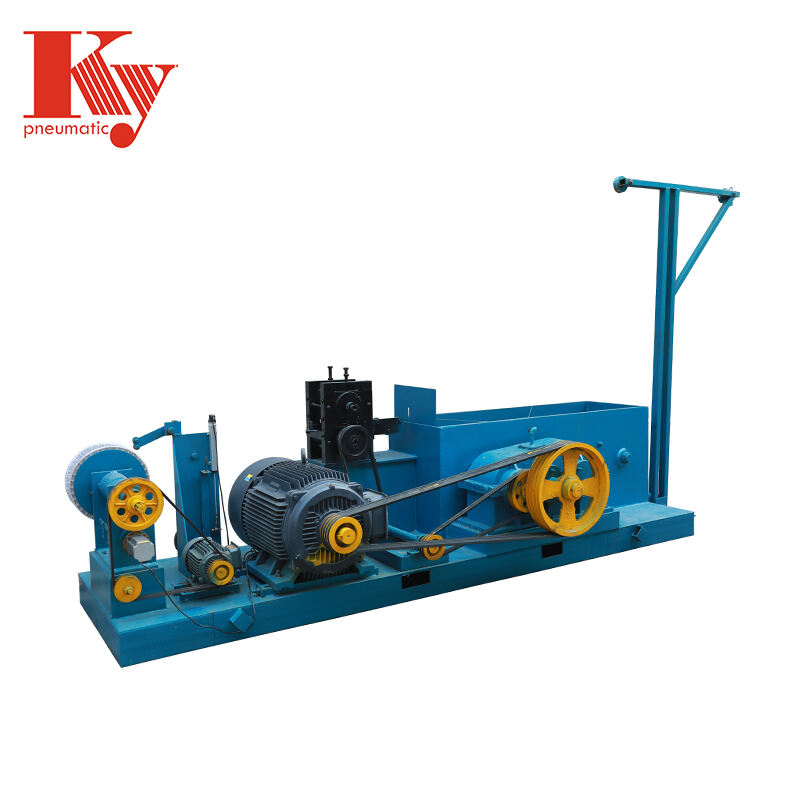

KY Pneumatic Wire Drawing and Flattening Machine

Technical Specifications and Error Rate Precision

What makes the KY Pneumatic Wire Drawing and Flattening Machine so special? Look no further than its specs that deliver both accuracy and power when it counts. Built with a tough alloy rim, this bad boy can tackle all sorts of strong iron wires, even those pesky spring steel varieties that give other machines trouble. The real kicker? Its flattening accuracy stays under 0.001mm most of the time, something manufacturers in the nail business haven't seen before. Factory workers who've used these machines report they just keep going day after day without issues, while still producing parts that fit perfectly together. For shops dealing with different wire types and thicknesses, this machine handles everything from thin gauge stuff to heavier duty requirements without missing a beat.

Industrial Applications in Nail Manufacturing Plants

The KY Pneumatic Wire Drawing and Flattening Machine has become essential equipment in many nail manufacturing facilities across the country. Built primarily for mid to large scale operations, these machines help factories produce more nails while spending less money on materials and labor. Factory managers who have implemented this technology report seeing real differences in their daily output. One plant manager mentioned they were able to boost their weekly production by almost 30% after installing the machine. What makes it so valuable is the ability to customize wire drawing parameters according to different nail specifications. Some manufacturers need thinner gauge wires for specialty nails, others require thicker stock for heavy duty applications. The flexibility built into this system allows producers to adjust settings quickly without having to invest in multiple dedicated machines just for different product lines.

Comprehensive After-Sales Support and Maintenance

Global Service Network and Spare Parts Availability

Good after-sales support matters a lot when it comes to keeping nail manufacturing machines running well and lasting longer. We've built up a pretty comprehensive service network around the world so customers get help whenever they need it, no matter where their business happens to be based. Our team includes experienced technicians working out of certified service locations across different regions, all prepared to step in once someone buys one of our machines. Spare parts availability remains just as significant because having access to replacement components means less time wasted waiting for repairs. According to some research data, companies with fast spare part delivery systems see machine downtime cut down by more than half, which obviously helps keep production moving smoothly. Real world examples from various manufacturers also indicate that quick response times from our service teams lead to better outcomes on factory floors, ultimately making operations run more efficiently day after day.

Operator Training Programs for Optimal Machine Utilization

Good training for operators really makes a difference when it comes to getting the most out of machines while cutting down on mistakes. We've developed training that gives people hands on experience plus the know how they need to work with our nail manufacturing equipment properly. The courses cover both how things work in practice and the theory behind them something that helps operators deal with all sorts of challenges during their regular shifts. People who have gone through the program often mention seeing better results right away fewer errors and faster production times. When workers understand their machines better, they can keep running at peak performance day after day, which means more product gets made without unnecessary downtime. For companies looking to get serious about improving their nail production processes, spending time and resources on proper training for staff just makes good business sense.

EN

EN

AR

AR

BG

BG

CS

CS

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

LT

LT

SR

SR

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

AZ

AZ

KA

KA

BN

BN

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

KK

KK

UZ

UZ