Essential Maintenance Tips for Long-Term Staple Machine Performance

Essential Maintenance Practices for Staple Machines

Lubrication Protocols for Moving Components

Keeping staple machines well lubricated really makes them last longer. Most operators stick to a regular oiling routine, typically around once every hundred hours or so when things start getting worn down from constant movement. Picking out the correct lubricant matters just as much though. The stuff needs to work across whatever temperatures the machine sees daily and play nice with whatever metals were used during manufacturing. Machines with those automatic greasing systems tend to perform better since they cut down on mistakes people might make manually applying oil. Sticking with proper maintenance schedules means fewer breakdowns and less money spent fixing problems later on down the road.

Debris Removal and Cleaning Techniques

Keeping staple machines running at their best requires regular cleaning, something I've learned through years of hands-on experience. My approach includes a daily clean up targeting those pesky metal shavings, accumulated dust, and whatever else manages to find its way into the machinery. Over time these bits can really mess with how the machine works properly. When it comes to choosing cleaning products, care matters a lot because some chemicals will eat away at certain parts of the machine, particularly near delicate components. For getting rid of stubborn debris, nothing beats good old fashioned compressed air cans or heavy duty shop vacs. We've found these methods work wonders for reaching every nook and cranny where dirt likes to hide, making sure our equipment stays free from any build up that might cause problems down the line.

Hydraulic System Care Strategies

Hydraulic systems play a major role in how nail making machines work, so keeping an eye on them regularly makes all the difference in maintaining good performance and avoiding breakdowns. Checking fluid levels often keeps things running smooth and stops problems from happening when there's not enough fluid in the system. Changing those hydraulic filters at the right time matters a lot too either following what the manufacturer says or when pressure starts acting weird helps keep everything unclogged and working efficiently. Don't forget to look at the hoses and connections for any signs of leaks either because ignoring small issues here tends to turn into big headaches down the road. Fixing these kinds of problems fast will make sure the staple maker lasts longer and works reliably over time. Good maintenance habits around the hydraulic system actually boost both the quality and output of staple production across the board.

Scheduled Inspection Routines

Setting up regular inspection routines makes a big difference when it comes to keeping staple machines running at their best. Most shops find that checking equipment once every week or two weeks works well enough to catch those early warning signs of wear and tear before they turn into bigger problems. When doing these checks, take notes on everything from minor scratches to unusual noises the machine might be making. Keeping good records actually becomes pretty valuable down the road because patterns start showing up in how different parts degrade over time. And don't forget to grab a checklist for each inspection session too. A solid checklist reminds technicians to look at safety features like emergency stops and also spot check key performance metrics across all major components. This simple step cuts down大大 on chances someone misses something important during routine maintenance.

Wear Pattern Analysis for Parts Replacement

Looking at how parts wear down over time helps figure out how long components in staple machines will last before needing replacement. When we do this kind of analysis, it becomes clear which parts break down faster than others, so maintenance plans can be adjusted to match what actually happens on the shop floor. Checking things visually along with using proper measuring instruments makes all the difference when spotting unusual wear patterns that might signal bigger problems hiding inside the machinery. Following what the manufacturers say about wear signs for each specific machine model matters a lot too. Their recommendations give us a good idea of normal wear rates across different parts, allowing technicians to swap out vulnerable components before they cause major breakdowns during production runs.

Moisture Control in Electrical Systems

Keeping moisture out of electrical systems matters a lot when it comes to avoiding short circuits and equipment problems, particularly where there's lots of humidity around. Putting in place things like desiccant packs or proper humidity controls helps keep everything running smoothly while protecting those sensitive electrical parts from damage. Checking electrical panels and connections regularly for signs of rust or water getting in shouldn't just be done once in a while. Anyone who works with electrical systems knows this stuff needs constant attention. Fixing moisture issues fast extends how long equipment lasts and cuts down on the chance of major electrical failures that can shut down whole operations. That means machines stay running reliably day after day without unexpected breakdowns.

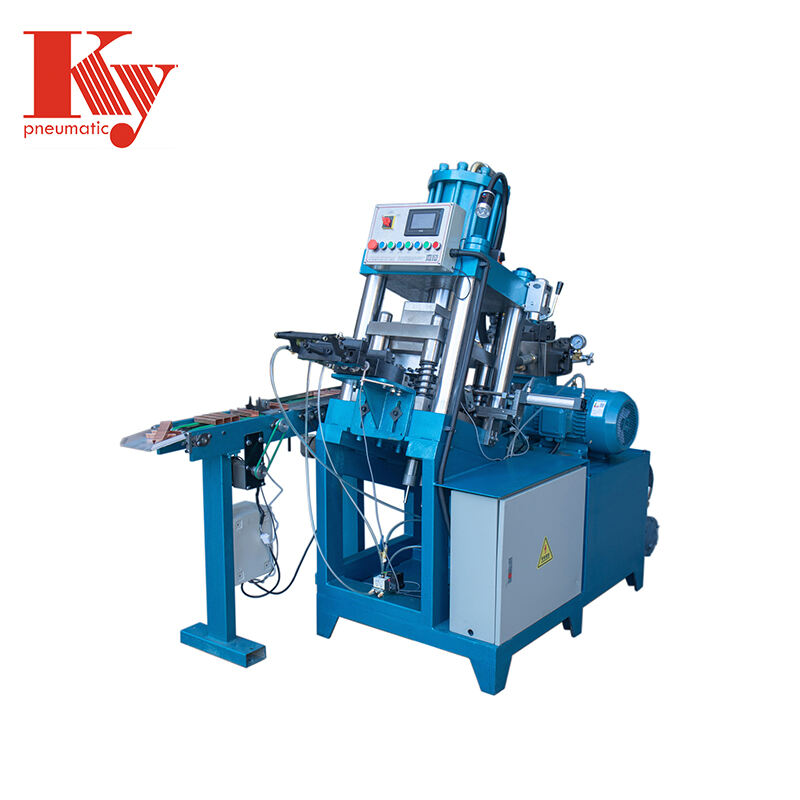

Hydraulic Carton Staple System with Automatic Lubrication

Automatic lubrication systems really help extend the life of hydraulic staple systems because they cut down on friction and wear over time. What makes these systems so valuable is that they keep applying lubricant consistently without someone needing to constantly check or refill them manually. This means less downtime for maintenance and better overall performance from the machinery. When companies install these kinds of systems, operators generally find their equipment runs smoother for longer periods between service checks. The reduced maintenance frequency translates into cost savings and fewer production interruptions in manufacturing settings where every minute counts.

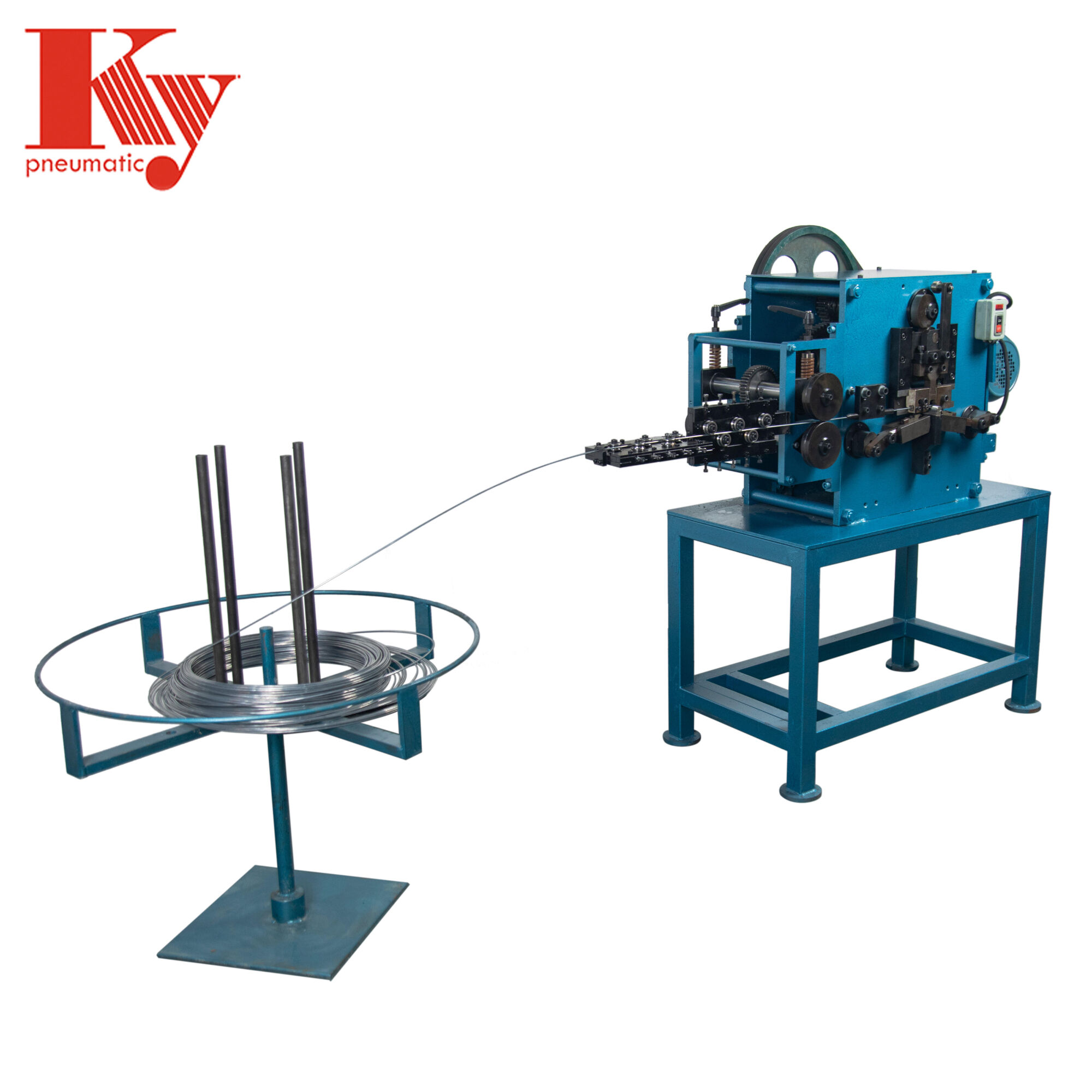

C-Ring Production Unit with Precision Alignment

Precision alignment in C-Ring production units significantly reduces wear and tear, thereby enhancing the durability and consistency of product quality. For instance, machinery with precise alignment capabilities is proven to improve operational efficiency by maintaining accurate production processes and reducing the need for frequent adjustments.

High-Speed Carbon Steel Staple Press with PLC Monitoring

PLC monitoring plays a crucial role in high-speed carbon steel staple presses, offering real-time diagnostics to facilitate preventive maintenance. By utilizing advanced monitoring, manufacturers can anticipate and address potential issues, significantly reducing downtime and maintaining production continuity.

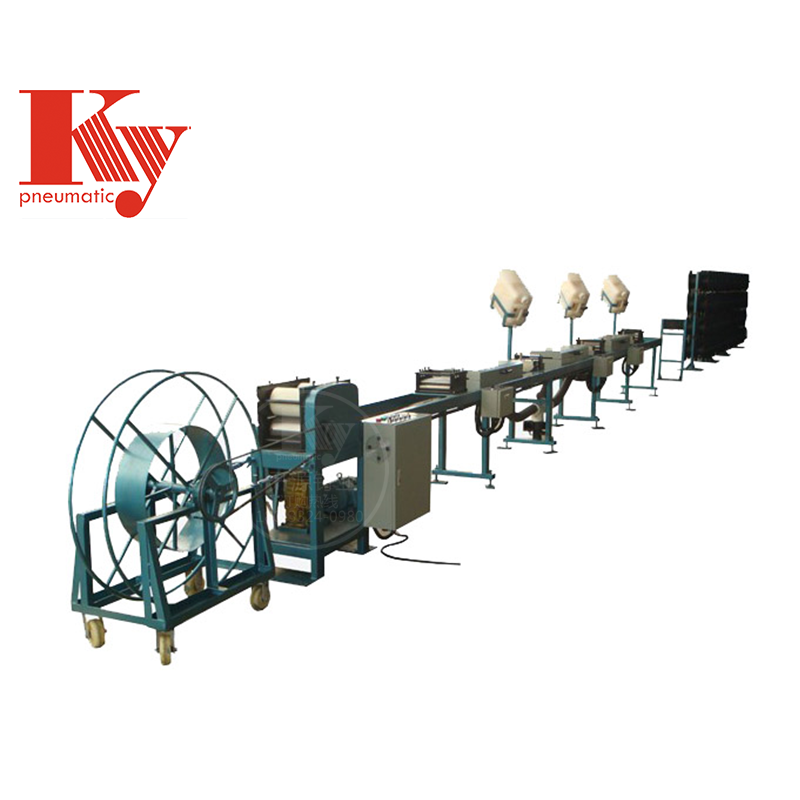

Full-Cycle Wire Band Machine with Self-Diagnostics

Self-diagnostic features are essential in wire band machines as they alert operators to maintenance needs, preventing minor issues from becoming critical. This technology significantly reduces downtime and boosts efficiencyâstudies indicate that such innovations can improve operational effectiveness by up to 70%.

Servo-Driven Heavy Duty Staple Maker

Servo-driven systems offer substantial benefits in heavy-duty staple making, providing enhanced energy efficiency and precision. Industry experts acknowledge that servo technology allows for improved operational effectiveness, offering seamless and accurate motions for consistent product quality.

Diagnostic Tools for Predictive Maintenance

Vibration Analysis for Bearing Health

Vibration analysis stands out as one of the best ways to spot potential bearing problems before they cause major issues with machines. When technicians measure how equipment shakes during operation, subtle changes often reveal early signs of wear or damage in bearings weeks or even months ahead of actual failure. The advantage here goes beyond just avoiding surprises it actually helps keep machines running longer between replacements. Most industries now follow guidelines set by groups like ISO when setting up their maintenance schedules. These standards recognize that regular vibration checks offer real money savings over time, cutting down on both unplanned stoppages and expensive repair bills that come from sudden breakdowns.

Thermal Imaging for Circuit Assessments

Thermal imaging stands out as one of the best ways to spot components running too hot inside electrical circuits before they cause bigger problems down the line. When we look at circuits through thermal cameras, we see where heat builds up abnormally, pointing us right to trouble spots without having to tear things apart. According to research published in the Electrical Engineering Journal, a factory actually cut their electrical breakdowns by nearly a third after implementing regular thermal checks across their operations. The ability to catch these issues early means fewer unexpected shutdowns and safer working conditions overall for anyone dealing with electrical systems on a daily basis.

Automated Alert Systems Integration

Adding automated alert systems to maintenance operations makes all the difference when it comes to letting staff know about pressing maintenance tasks. These kinds of systems allow plant personnel to jump on problems fast, cutting down how long it takes to respond and keeping equipment running longer between breakdowns. Real time data combined with smart analytics helps spot potential trouble spots before minor issues turn into major headaches. A recent article from Maintenance Technology highlighted some real world results where businesses saw around 40 percent fewer unexpected shutdowns after installing these alert systems, showing just how valuable they are for proactive maintenance planning. When maintenance crews have access to these alerts, they simply handle repairs faster and get things back online quicker, which means better production numbers across the board.

EN

EN

AR

AR

BG

BG

CS

CS

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

LT

LT

SR

SR

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

AZ

AZ

KA

KA

BN

BN

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

KK

KK

UZ

UZ