Advantages of Using High Speed Nail Making Machines in Mass Production

Enhanced Production Capabilities with High-Speed Nail Machines

Unmatched Speed and Output in Nail Manufacturing

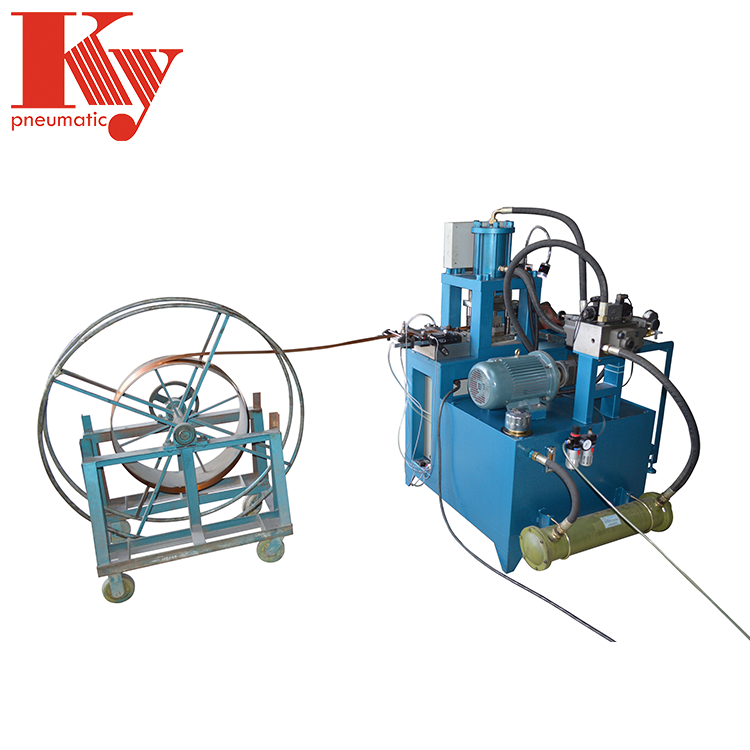

The nail manufacturing sector has seen major changes thanks to high speed nail making machines that deliver incredible output levels. Industry reports suggest certain models can churn out around 600 nails every minute, which really boosts production capabilities. What makes these machines so fast? Automation plays a big role here, cutting down on downtime and keeping operations running smoothly most of the time. For manufacturers dealing with growing market demands, this kind of performance matters a lot. Modern tech built into these systems keeps cycle times consistent, something that directly affects how productive a factory can be. Companies that adopt this technology gain a serious edge in staying competitive while still meeting customer deadlines consistently across different product lines.

The nail industry covers everything from building homes to crafting custom furniture, so manufacturers who want to stay competitive need fast nail production equipment. High speed nail makers cut down on manual work while keeping quality consistent across batches. They save money on wages too since fewer workers are needed to operate them compared to traditional methods. For businesses looking to grow, getting one of these machines often means the difference between struggling to meet orders and consistently delivering what customers want. A local hardware store owner told me recently how his shop doubled output after installing a new nail maker last year.

Precision Engineering for Consistent Quality

What sets high speed nail making machines apart is their precise engineering design that makes sure every single nail hits those tough quality benchmarks. Inside these machines there are pretty smart quality checks built right in. They spot any flaws as they happen on the production line, so bad products don't get through. This means better reliability overall for the finished product. When manufacturers invest in these kinds of systems, they end up with nails that stay consistently good quality batch after batch. And let's face it, customers appreciate this because fewer defective items mean fewer returns and happier clients in the long run.

The accurate measuring tech built into these machines really matters when it comes to keeping those nail sizes consistent across the board. Without this kind of precision, manufacturers would struggle to produce nails that actually fit what the industry needs and what customers expect from their hardware store purchases. A good nail production machine does more than just speed things up though it makes sure every single nail coming off the line hits those quality marks consistently. For companies trying to build trust and maintain a solid name in the market, investing in machines designed with precise engineering isn't just smart business it's practically necessary if they want to keep delivering nails that perform reliably day after day on job sites everywhere.

Cost-Efficiency in Mass Nail Production

Reduced Labor Costs Through Automation

When it comes to nail manufacturing, automation really brings down those labor costs. Industry reports suggest savings can hit around 30% when plants switch to automated systems. The high speed machines take over most of the work, so factories need far fewer workers on the floor. Production runs smoother this way, with less hands-on time required from staff. Beyond just cutting payroll expenses, these machines also mean less money spent on overtime pay and constant employee training sessions. For businesses trying to pad their bottom line, getting serious about modern nail making equipment makes good financial sense. Many manufacturers have found that upgrading their machinery pays off pretty quickly in terms of both wallet and workflow improvements.

Material Optimization and Waste Minimization

Today's nail production equipment really cuts down on material waste while making manufacturing much more sustainable overall. Most factories now have systems in place to collect leftover metal scraps and melt them down again for reuse. This means less raw material ends up in landfills and companies get more value from what they already have. The machines themselves incorporate advanced cutting techniques that waste almost nothing during production runs. For manufacturers looking to cut costs without sacrificing quality, these improvements represent a win-win situation. As consumers become increasingly concerned about environmental impact, businesses adopting such practices tend to stand out in the marketplace simply because they're doing things differently than competitors who still generate massive amounts of waste.

Advanced Technological Features for Industrial Demands

PLC Control Systems for Customizable Production

In today's nail manufacturing world, Programmable Logic Controllers or PLCs play a huge role because they give factories the ability to adjust their operations based on what clients need. The truth is these advanced control systems let manufacturers change how they produce nails pretty easily, switching from one style to another without losing much time on the production floor. When there's a sudden shift in what customers want or when market conditions change, having PLCs means factories can respond faster without major disruptions. For businesses trying to stay ahead in this fast moving industry, being able to handle custom orders becomes a big plus. That's why so many companies across the sector keep looking for nail making equipment that comes with built-in PLC technology. After all, nobody wants to be stuck producing standard sizes when everyone else is offering specialty designs these days.

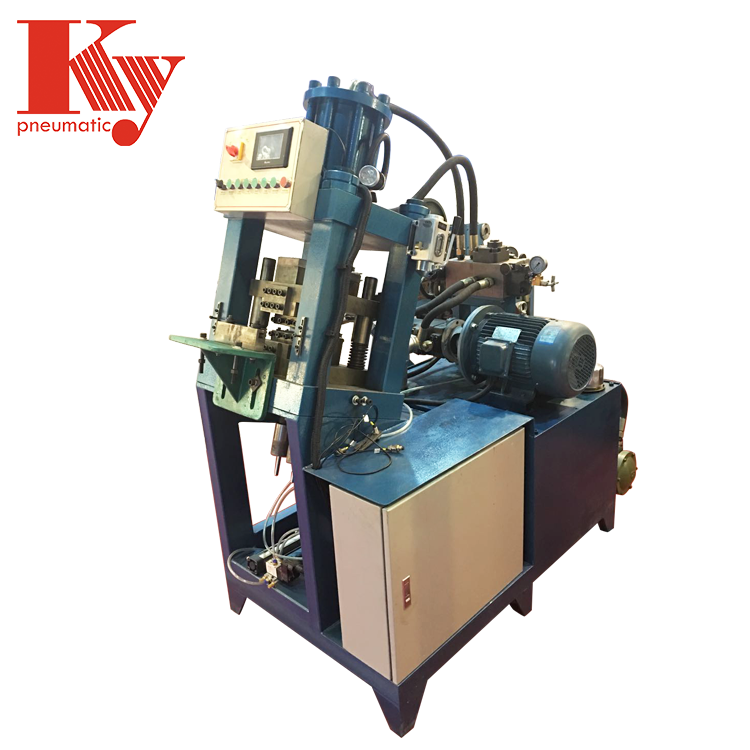

Durable Mold Designs and Lubrication Systems

What makes high speed nail production machines so efficient? A lot has to do with how well they're built, particularly the durability of their molds and the quality of their lubrication systems. Good mold design means these machines last longer before needing repairs, which cuts down on those costly maintenance bills and keeps production running without surprises. Strong molds hold up under constant pressure during fast paced manufacturing cycles. Meanwhile, smart lubrication systems keep everything moving smoothly by cutting down on friction points where parts rub together too much. When both elements work together properly, there's less time spent fixing things when they break down, plus factories can crank out nails at higher speeds. For companies dealing with big orders from construction sites or hardware stores, this kind of setup matters a ton. Without reliable molds and effective lubrication, keeping up with volume requirements becomes nearly impossible in today's competitive market.

Top High-Speed Nail Making Machines for Sale

T Brad Nail Machine: Dual-Solution Flexibility

What makes the T Brad Nail Machine so special? Its dual solution flexibility has made it a go to option for many manufacturers who need versatility in their nail production. The real advantage comes from being able to switch between various nail sizes without much hassle at all. This cuts down on those frustrating setup times when changing configurations. For companies wanting to offer more products but still keep things running smoothly, this machine hits the sweet spot. Just imagine what kind of business growth possibilities open up when production can handle multiple sizes while maintaining good output speeds.

F Brad Nail Machine: Rapid Production for Fine Gauges

The F Brad Nail Machine really shines when it comes to producing those super thin gauge nails quickly. Markets that need precise measurements and top notch finishes just can't do without it these days. What sets this machine apart is how it keeps going at breakneck speed while still maintaining nail quality standards. Manufacturers are noticing as demand grows for these fine gauge products across construction and specialty applications. For shop owners looking to expand their capabilities, investing in one of these machines makes solid business sense given the current market trends toward higher quality fasteners.

Auto Pneumatic Brad Machine: Dual-Operation Efficiency

The Auto Pneumatic Brad Machine combines pneumatic power with mechanical components to get twice the work done in half the time. Great for factories cranking out thousands of nails daily, this setup means operators don't need to babysit the process constantly, which marks a big leap forward from older models that required constant attention. Factory managers across the country tell similar stories these days about their bottom lines improving after switching to this system. Some plants report cutting their monthly operating costs by as much as 30% simply because they're producing more nails without spending extra on labor or materials.

T/F Series Machine: Multi-Gauge Versatility

The T/F Series Machine handles all sorts of nail sizes from thin wire nails to heavy duty construction staples, which means it works great across different markets. What really stands out is how easy it is to tweak settings between jobs. Just a few minutes spent adjusting parameters lets the machine switch from one type of nail to another while keeping production running smoothly. For manufacturers dealing with changing orders and unpredictable demand, this kind of versatility gives them an edge. Companies can respond faster to customer requests without having to invest in multiple specialized machines, something that becomes increasingly valuable as market conditions shift constantly these days.

EN

EN

AR

AR

BG

BG

CS

CS

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

LT

LT

SR

SR

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

AZ

AZ

KA

KA

BN

BN

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

KK

KK

UZ

UZ