How Automatic Nail Making Machines Improve Factory Efficiency

How Automatic Nail Making Machines Revolutionize Factory Efficiency

Eliminating Manual Labor in Nail Production

Nail making machines have changed how nails get produced by handling most steps automatically, which cuts down on manual work requirements. These sophisticated devices handle all those tedious jobs that used to require lots of hand labor, including cutting metal strips, forming them into proper shapes, and giving them that smooth finish we expect. Factories benefit from lower payroll expenses while workers face fewer risks since they're not constantly handling sharp materials anymore. Looking at industry data shows pretty impressive time reductions when switching from old school methods to automation. Some plants report their machines crank out nails around four times quicker than what human workers could manage before, though results do vary based on specific machine models and operational conditions.

Increasing Output with High-Speed Automation

The introduction of high speed automation in nail manufacturing could really boost what factories produce overall. Modern automatic nail makers running at top speeds churn out way more nails each hour compared to old school methods from just a few years back. The jump in productivity means better bottom lines too, since plants can keep up with customer needs faster and sell more product across different markets. Industry insiders have seen some pretty impressive returns on investment when companies go all in on these fast production systems. Beyond just making more stuff, these machines actually improve how accurate and consistent the final products are, something absolutely essential when producing thousands upon thousands of nails daily. Take one manufacturer who switched to high speed tech last year saw their output shoot up around 50%, which translated directly into extra revenue streams and expanded market share within months.

Key Features Driving Operational Excellence

PLC Control for Precision Manufacturing

The adoption of Programmable Logic Controllers or PLCs has really transformed how accurate nail production can be these days. Nail manufacturing equipment equipped with PLC systems maintains tight control over everything from nail size to finish quality, so products stay consistent even when running through thousands of units. What makes these systems valuable is their flexibility for programming different production settings based on what customers need, which cuts down mistakes during manufacturing. Industry reports indicate error rates drop by about 40% when switching from manual operations to PLC controlled setups. This reduction means substantial savings for manufacturers while delivering better quality products to market.

Adjustable Speed for Flexible Production Demands

Adjustable speed settings on nail making machines make all the difference when production needs change from day to day. With these settings, factories can actually match their output pace to whatever's happening in the market or when clients suddenly need huge quantities right away. No extra workers needed just to keep up with rush orders. Take construction equipment manufacturers for example they've been able to ramp up production during peak seasons without breaking their budgets. The real value here isn't just about saving money on labor costs though. When a factory can adjust speeds as needed, it opens doors to grab unexpected business deals too. Some smaller operations even report being able to compete against bigger rivals simply because they could respond faster to changing customer needs without eating into their profit margins.

Error-Reduction Technology for Consistent Quality

The latest error reduction tech built into modern nail manufacturing equipment has really cut down on mistakes made by workers during production runs. These machines come equipped with automatic inspection systems that check every single nail against what the industry considers acceptable quality levels. This means factories throw away way less material and end up with far fewer faulty products heading out the door. Looking at real world examples tells us something interesting about this trend. One particular plant shared results showing their defect rate dropped by around 40% after they installed these new systems. What this shows is pretty straightforward actually - when manufacturers invest smartly in good technology, they get better quality nails while their entire operation becomes more efficient over time.

These features collectively contribute to the operational excellence of factories utilizing automatic nail making machines by increasing precision, flexibility, and quality assurance, making them indispensable in today’s competitive manufacturing landscape.

Top Automatic Nail Manufacturing Solutions

T Brad Nail Machine: Dual-Mode Production Flexibility

What makes the T Brad Nail Machine really special is its dual mode production system that lets operators switch back and forth between manual settings, semi auto functions, and full automation without missing a beat. This kind of flexibility means factories can handle different production volumes day to day without wasting time or resources. Factory managers we spoke to mentioned how they were able to ramp up output during peak seasons just by flipping a switch on the control panel. One manufacturer in particular told us their customers noticed fewer delays in order fulfillment since they could adjust production speeds so quickly. The machine's versatility has become something of a game changer for small to medium sized operations trying to keep up with unpredictable market trends while still maintaining quality standards.

F Brad Nail System: Compact Powerhouse for Small Gauge Nails

The F Brad Nail System stands out as a space-saving solution for producing small gauge nails, which works great when workshop space is at a premium. Even though it's smaller than most competitors, this machine doesn't skimp on performance, delivering results that hold their own against bigger models on the market. With specs including a production rate reaching around 160 nails every minute, many manufacturers who specialize in these tiny fasteners find it hard to beat. What makes this equipment so appealing? It manages to churn out decent volumes without taking up much floor space, something that matters a lot to shops where square footage comes at a cost.

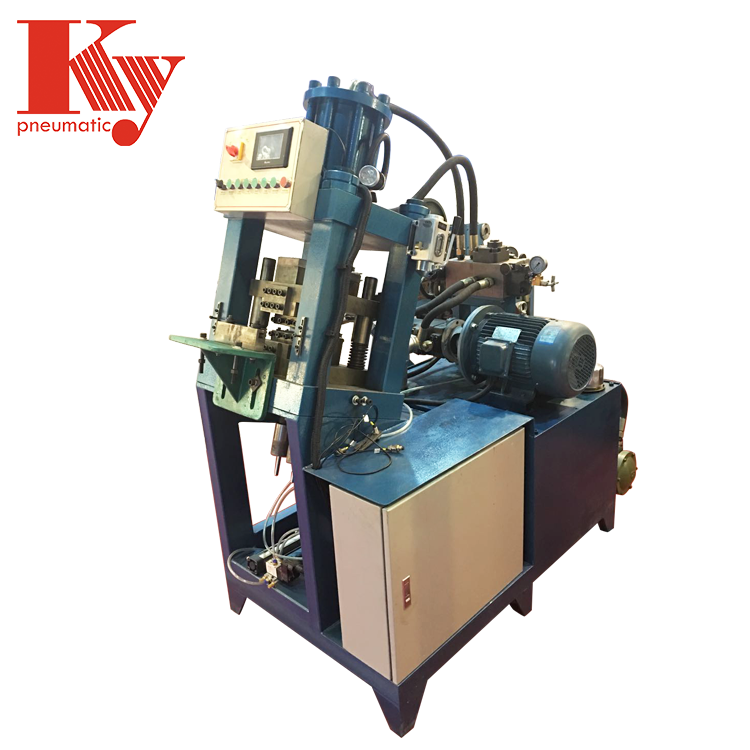

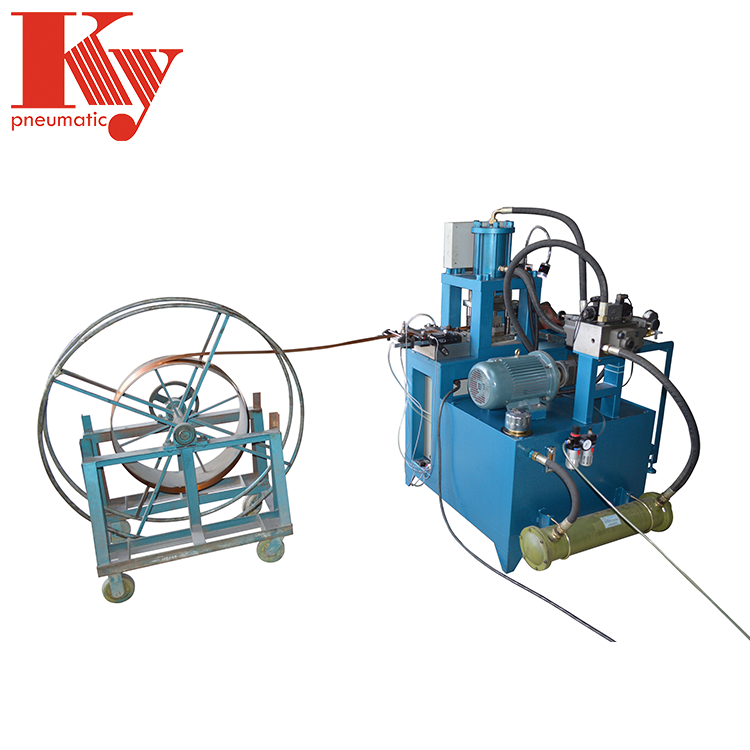

Auto Pneumatic Model: Dual-Operation Productivity Boost

The Auto Pneumatic Brad Nail Making Machine really stands out thanks to its dual operation setup. With this design, one worker can handle two machines at once, which cuts down on downtime and gets more nails made per shift. Manufacturing plants love this kind of machine because they need so many brads produced daily but don't want to hire extra staff for each unit. We've seen these machines work wonders across different shops and factories, boosting their production numbers significantly. When companies switch over to this pneumatic system, they typically notice a jump in output right away. What's even better? The nails come out just as consistent and strong as before, so there's no compromise on quality despite the faster pace.

T/F Series Hybrid: Versatile Multi-Gauge Capability

What sets the T/F Series Hybrid apart is its capacity to produce different nail gauges, something that addresses many manufacturers' needs across various projects. The fact that it handles multiple sizes means production lines stay flexible when orders change or new products come into play. People running operations with these machines often mention how much easier it becomes to manage different customer requests without constantly switching between equipment. No need for extra machines sitting around collecting dust while waiting for specific jobs. For shops trying to keep up with market changes, having one machine that works with several nail sizes turns out to be pretty essential for staying competitive without breaking the bank on specialized tools.

Sustaining Efficiency Through Machine Longevity

Automatic Lubrication Systems for Continuous Operation

Automatic lubrication systems make a real difference when it comes to keeping machines running smoothly while cutting down on downtime. When parts get properly lubricated regularly, they don't wear out as fast and there's less chance of unexpected problems stopping operations. Some companies that switched to these automated systems saw their maintenance downtime drop by around 30 percent according to industry reports. Most mechanical experts will tell anyone who asks that good maintenance practices directly affect how reliable equipment stays over time. Regular oiling not only makes machines last longer but also keeps production moving at consistent levels without unnecessary interruptions.

Industrial-Grade Molds for Extended Service Life

Putting money into industrial grade molds makes machines last longer and saves cash on replacements while keeping them running more consistently. These heavy duty molds are built to handle what happens every day on factory floors, so breakdowns become less frequent. Some studies show that when manufacturers switch to industrial grade molds, they often see their equipment lasting about 50% longer before needing replacement parts. And looking at actual shop floor data, businesses that adopt these stronger molds tend to replace components far less often than those sticking with standard options. This means not just saving money over time but also getting better performance from machinery investments.

Global Technical Support Networks

A global technical support network makes all the difference when it comes to keeping machines running smoothly day after day. When companies can get help fast, they spend less time waiting around for repairs and more time actually producing goods, which matters a lot when there are tight deadlines to meet. Real world experience shows that factories with good support systems see their downtime drop significantly. One plant manager told us about how getting same day fixes saved them thousands during peak season last year. What's more, these support networks let manufacturers maintain consistent operations no matter where their facilities are located. Whether in Asia or Europe, problems get solved quickly enough so production doesn't fall apart at the seams.

EN

EN

AR

AR

BG

BG

CS

CS

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

LT

LT

SR

SR

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

AZ

AZ

KA

KA

BN

BN

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

KK

KK

UZ

UZ