The Growing Applications of Hog Ring Machines Across Industries

Key Industries Utilizing Hog Ring Machines

Agricultural Sector: Cage Manufacturing & Crop Support

Hog ring machines have become essential equipment across agriculture, mainly used to build cages for animals and support structures for crops. What makes these machines stand out is how quickly they connect wires together securely, so whatever gets built stays strong without needing constant fixing later on. Farmers actually save money in the long run because these structures last much longer than alternatives. When crops get proper support from hog rings, harvests tend to be better. Livestock stays put where it should too, since the fencing holds up under pressure. For most farm operations, this kind of reliability means fewer headaches during busy seasons when every minute counts.

Product Name: Agricultural Hog Ring Machine

Automotive Industry: Seat Assembly & Upholstery

Hog ring machines play a vital role across the automotive sector, especially when putting together car seats and interior components where strength matters most. These devices offer quick and reliable fastening solutions that keep assembly lines moving smoothly without hiccups. Factory workers know from experience that implementing hog ring technology often means fewer man hours spent on manual fastening tasks while boosting output rates substantially. That explains why major automakers have been turning to this equipment for decades now in their seat manufacturing processes and throughout various upholstery operations inside vehicle plants.

Furniture Production: Mattress & Sofa Manufacturing

Hog ring machines play a big role in making furniture these days, especially when it comes to putting together mattresses and sofas. What makes them so valuable is how they secure materials together reliably, giving furniture better structure and lasting power over time. Industry data shows that factories using hog ring technology tend to boost their output speeds around 30% compared to older methods. Manufacturers see real benefits here too since faster production means getting more units out the door while spending less money on labor costs. That's why so many companies across the furniture sector have started incorporating hog rings into their manufacturing processes recently.

Construction Applications: Gabion Baskets & Wire Mesh

Hog ring machines are really important in construction work, particularly when building things that need extra reinforcement. These machines help create those gabion baskets and wire mesh panels that engineers rely on for all sorts of civil projects. Gabions themselves are basically rock-filled cages that hold up retaining walls and stop soil erosion along riverbanks. What makes hog rings so good at their job? Well, the way they fasten materials together creates something pretty tough and long lasting. This strength matters a lot because many engineering projects depend on stable foundations. Retaining walls especially need this kind of support since they're constantly fighting against earth pressure and sometimes even water forces from below ground level.

Technological Advancements in Hog Ring Machinery

Precision Automation for High-Volume Output

The latest improvements in hog ring machinery now feature precision automation that really boosts what these machines can produce when running at scale. For manufacturers who depend on hog ringers day in and day out, this marks a real shift in how operations run. These new automated setups work much faster than before without sacrificing quality, something plant managers notice immediately when orders start coming through quicker. According to industry reports, facilities switching to automation typically see around a 50% jump in production numbers over traditional methods. The difference shows up not just in quantity but also in consistency across different product lines.

Multi-Material Compatibility Features

Today's hog ring machines come equipped with features that let them handle different materials, which is pretty handy when production needs change from day to day. The ability to switch between materials means factories don't need separate machines for each type, cutting down on expenses and freeing up valuable floor space in the workshop. Industry insiders point out that this kind of versatility gives manufacturers much more freedom in their operations. They can choose from a wider range of materials without having to compromise on how well things get done or the final product quality. Some plants report being able to take on new contracts they previously couldn't handle because of these upgraded capabilities.

Energy Efficiency & Low-Noise Operation

More and more factories are turning to energy efficient hog ring machines these days because green manufacturing has become a top priority across many sectors. What makes these machines so attractive? They cut down on power usage while also making workplaces quieter, which means workers don't have to deal with constant loud noises anymore. Some studies show that switching to these efficient systems can actually save companies around 20 percent on running costs without sacrificing production quality. For manufacturers looking to reduce their carbon footprint without breaking the bank, investing in energy efficient hog ring technology isn't just smart business it's becoming practically standard practice in today's environmentally conscious market.

Industrial-Grade Hog Ring Machines: Product Overview

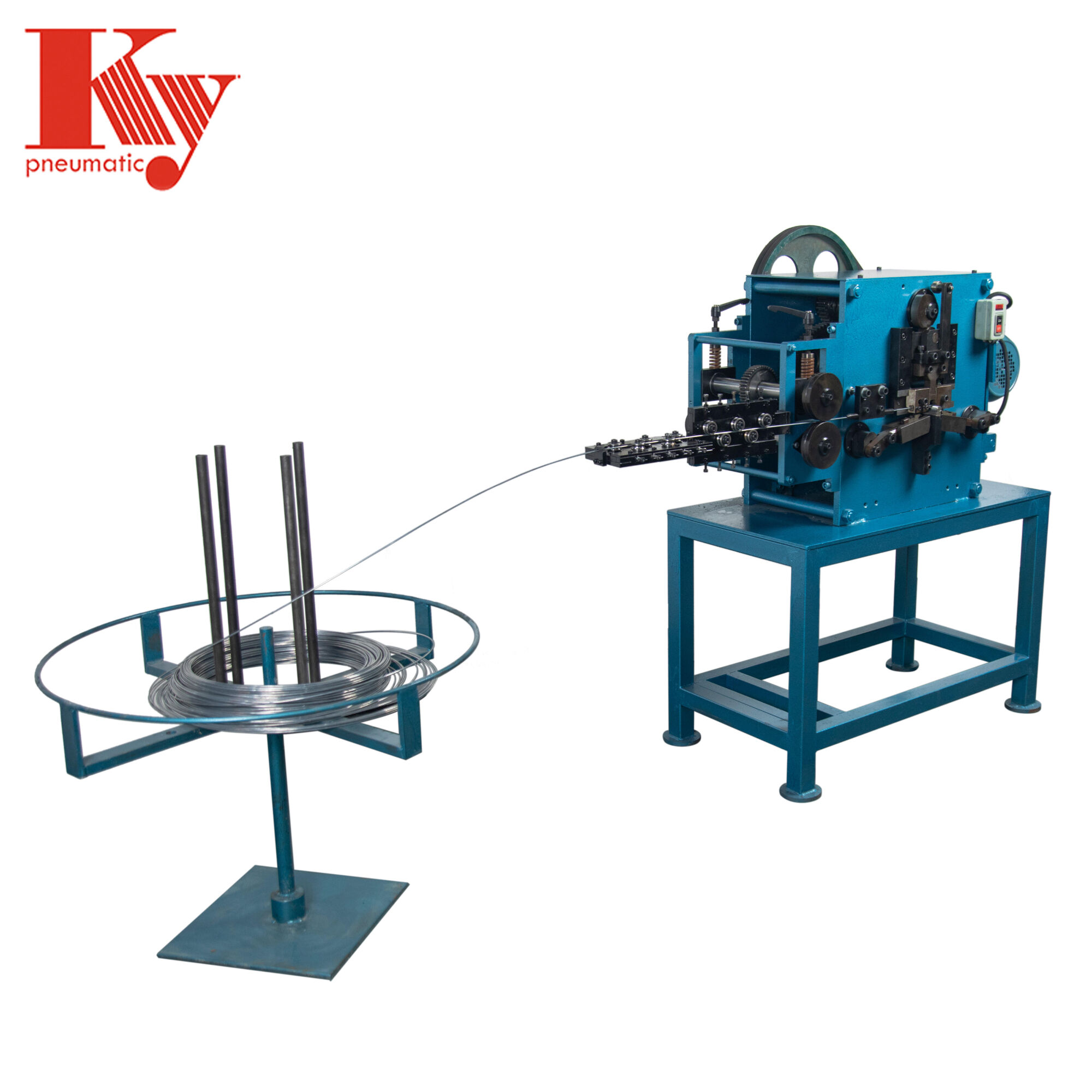

Hog Ring Machine: Full-Automation for Diverse Applications

Full automation has transformed hog ring machines into workhorses that deliver real advantages in manufacturing settings. When operators step back from the process, these machines maintain quality standards consistently while slashing error rates on the production floor. Most modern models come equipped with built-in counters and precise nail cutters, so every finished product meets exact specifications without fail. What makes them stand out? They can tackle everything from securing chicken coops to assembling automotive components, adapting seamlessly between different product lines. As factories grapple with tighter budgets and shrinking workforce numbers, many manufacturers are finding that investing in automated hog ring systems pays off handsomely over time through both reduced waste and faster throughput.

C Ring Staple Hog Ring Making Machine: Specialty Fastener Production

When it comes to making those special ring staples, the C Ring Staple Hog Ring Making Machine really shines. Built for speed, this machine handles rush orders without breaking a sweat while still keeping things efficient. What sets it apart are the internal systems that cut down on scrap material during production, which helps reduce environmental impact over time. The machine can churn out different types of fasteners too – think C-rings and D-rings – so manufacturers across various sectors find it useful. From assembling furniture pieces to securing parts in vehicles, this versatility means businesses don't have to switch between machines for different jobs. As companies increasingly focus on greener manufacturing practices, having equipment like this becomes essential for staying competitive while meeting today's sustainability standards.

Selecting Hog Ring Machines for Operational Needs

Assessing Production Volume Requirements

The selection process for hog ring machines really comes down to how much product needs to move through the facility each day. When manufacturers take stock of their actual output requirements, they're better positioned to pick equipment that matches what their operation actually needs. Small shops often find themselves stuck with expensive heavy duty models sitting idle most of the time because they simply don't have enough work to justify the cost. Big operations tell different stories though. Automated systems pay off handsomely over time as they crank out parts at consistent speeds without breaking a sweat. Industry data keeps pointing toward one clear trend these days the companies that match their machinery capabilities to their production realities tend to run smoother and save money in the long haul.

Evaluating Workspace Constraints

When choosing hog ring machines, looking at the actual workspace matters a lot because how big or small the area is and what's already there determines which machines will actually fit. Running into space problems later on can really mess with how well these machines work together and might slow down production. Most people who know about this stuff suggest drawing out exactly where everything goes before buying anything new. Getting this right from the start means fewer surprises down the road when trying to install equipment. A good layout plan helps keep things running smoothly while making sure every inch of floor space gets used properly instead of wasting valuable room.

Comparing Pneumatic vs Electric Systems

The decision between pneumatic and electric hog ring systems really comes down to what matters most for day-to-day operations. Pneumatic models need more regular upkeep but work great when speed matters most, which explains why many meat processing plants still rely on them despite the extra maintenance. Electric alternatives tend to save money over time since they run cleaner and require fewer parts replacements. Some industry reports suggest switching from one system to another could change overall expenses by around 15% or more depending on usage patterns. For companies trying to balance budgets without sacrificing productivity, looking closely at these different aspects becomes important. After all, no two facilities have exactly the same requirements when it comes to equipment selection.

EN

EN

AR

AR

BG

BG

CS

CS

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

LT

LT

SR

SR

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

AZ

AZ

KA

KA

BN

BN

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

KK

KK

UZ

UZ