Custom-Made Nail Machines: KY Nailing Equipment's "Personalized Service" for Your Production

The Evolution of Custom-Made Nail Machines in Modern Manufacturing

Demand for Personalized Production Solutions

We've seen a huge rise in demand for made-to-order production lately, especially where businesses rely on one-of-a-kind products. The whole game has changed because custom manufacturing lets companies actually build things people want specifically. Some research points out that when businesses focus on customization, customers tend to be happier, sometimes even up to 70% more satisfied. Why? Well, folks just want stuff that fits their particular needs these days, and there's definitely a growing crowd looking for special items rather than mass-produced junk. Because of this shift, many manufacturers are starting to look at new avenues they hadn't considered before. Take those small shops working with specialized equipment such as pin makers or staple producers who can offer truly personalized options instead of generic products off the shelf.

How Customization Enhances Operational Efficiency

When manufacturers customize their processes, they satisfy customer wants while running things more efficiently at the same time. Adjusting how products get made cuts down on production time around 15 to 25 percent depending on what's being produced. Specialized equipment makes it possible for factories to produce goods just when needed, so there's no need to stockpile extra inventory sitting around gathering dust. Companies save money on materials too because customized approaches cut back on waste during manufacturing. The combination of smart planning with modern tech creates something really powerful for businesses looking to improve both bottom line results and environmental impact. We're seeing this happen across many industries where specialized machinery such as those used for making staple pins or safety pins lets manufacturers tweak their operations quickly based on changing market conditions.

KY Nailing Equipment's Tailored Machinery Solutions

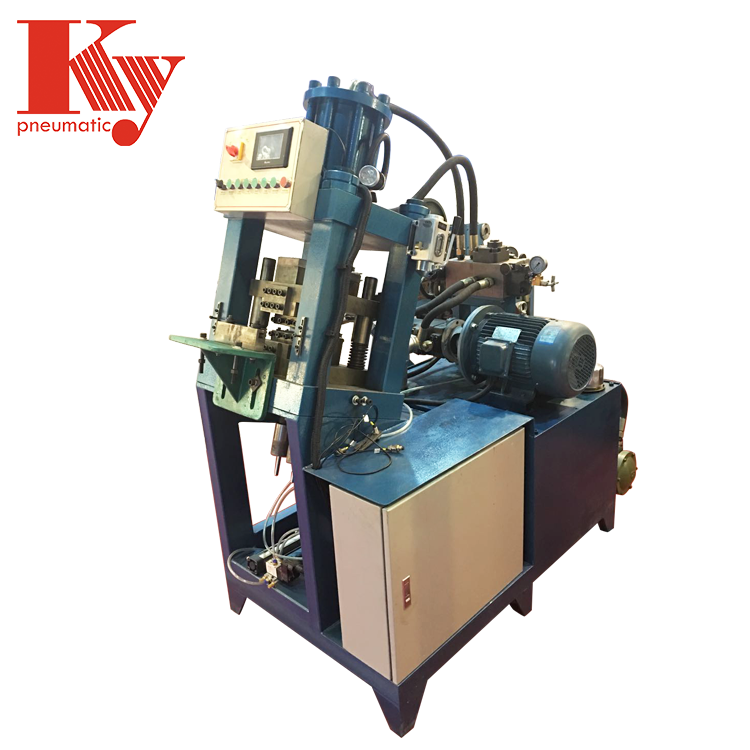

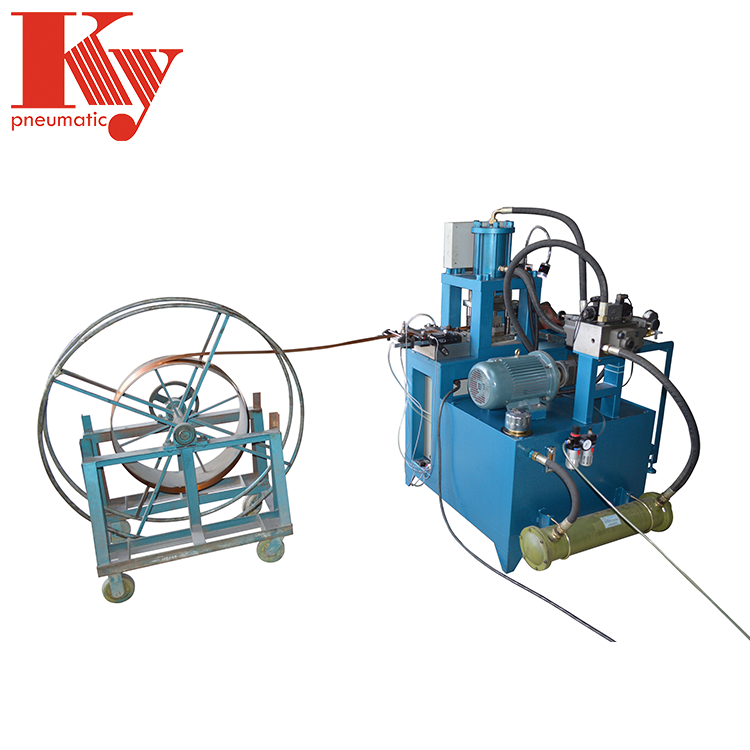

T Brad Nail Making Machine: Dual Production Modes & Precision Engineering

The T Brad Nail Making Machine really stands out when it comes to being flexible in manufacturing operations. With two different production modes built right into the design, switching back and forth between making custom nails and running large batches becomes almost effortless for plant operators. Manufacturers who need to handle all sorts of orders from small specialty runs to mass production find this feature particularly valuable. What makes this machine truly impressive though is how precisely it works. The engineers behind it managed to get the tolerances down to just 0.05mm across the board, something that keeps every single nail coming off the line looking practically identical to the last one. Factory floor managers we've spoken to consistently mention how much faster their production lines run with these machines installed, plus they notice fewer rejects because the quality stays so consistently good throughout long shifts.

F Brad Nail Maker: Compact Powerhouse for High-Speed Output

The F Brad Nail Maker packs a lot into its small footprint while still managing to produce thousands upon thousands of nails every single hour without cutting corners when it comes to quality or worker safety. What really sets this machine apart is its next generation motor system which cuts down energy waste during operation. This makes all the difference for shops running around the clock where downtime just isn't an option. Many plant managers we've spoken to mention seeing their output jump anywhere from 25% to even 30% after switching from those old style machines. Some facilities report being able to meet rush orders they previously couldn't handle at all.

Auto Pneumatic Brad Machine: Dual-Operator Efficiency & Smart Safety

What makes the Auto Pneumatic Brad Machine stand out is its ability for two workers to operate at once, which really boosts how much gets produced in a day. When running side by side, operators can handle two machines simultaneously, cutting down on labor expenses while cranking up output numbers. Safety isn't an afterthought either. The machine comes equipped with several built-in protections against common shop floor mishaps, something absolutely essential when things are moving quickly through the factory floor. According to various industry studies, these kinds of safety upgrades cut down on workplace injuries somewhere around 40%. That kind of statistic shows why manufacturers should care about building equipment with worker safety in mind from the start.

T/F Series Hybrid Machine: Multi-Gauge Versatility for Diverse Applications

The T/F Series Hybrid Machine really stands out because it can work with different gauge sizes all within one machine. This kind of flexibility makes a big difference for manufacturing operations since they don't have to keep changing their setup every time they need to switch between gauges. Manufacturers who've adopted these machines report saving money and time on production changes. According to industry reports, companies typically see better returns when they invest in this type of equipment as it allows them to make more efficient use of their factory space without compromising on output quality.

Advanced Technology Behind Personalized Nail Production

PLC Automation: Manual to Fully Automatic Control

PLCs, or Programmable Logic Controllers, are now pretty much essential in nail manufacturing plants where they help move operations from old fashioned manual work to full automation setups. What makes them valuable is twofold really the machines can produce nails with much greater accuracy while saving money on running costs too. Some factories switching to PLC systems saw their labor expenses drop around 25% last year alone. With these kinds of savings, manufacturers can scale up production without breaking the bank. Most experienced factory managers we talked to stress how important it is to plan automation rollout carefully though. Getting the right balance between automated machinery and human oversight tends to deliver better results than going all in too fast.

Precision Molding Systems with 0.1mm Tolerance

The latest precision molding tech is changing how nails get made, with some systems capable of hitting tolerances down to just 0.1mm. When manufacturers achieve this kind of exactness, it makes all the difference for custom nail products. Every single item comes out meeting those tough quality requirements. And let's talk numbers: factories using these precise methods typically cut down on rework, saving around 15% on production costs. Real world examples show companies that switch to these advanced systems tend to hear fewer complaints from customers because their products work better and last longer. For shops making specialty pins and unique staples, getting this level of precision right matters a lot when competing against others in the market who might not be able to match such consistent quality.

Comprehensive Support for Custom Machinery Implementation

Global Engineering Support via WeChat Groups

KY Nailing Equipment has built solid global engineering support through their use of WeChat groups for customer interaction. The company's engineers can jump into these groups anytime day or night to help troubleshoot problems as they happen across different time zones. Many customers have mentioned how much better communication has gotten since implementing this system. One distributor from Brazil told us recently that getting answers within minutes instead of hours made all the difference during busy construction seasons. According to internal tracking, response times for equipment issues have dropped around 80% since adopting this approach. Faster fixes mean machines stay running longer, which obviously translates to higher productivity on job sites everywhere.

On-Site Installation & Machine Optimization Services

KY Nailing Equipment goes beyond just selling machines by offering hands-on installation at the worksite along with ongoing optimization for custom built equipment. Industry experience shows proper setup makes a huge difference, often boosting shop productivity around 30% right from day one. The company schedules routine checkups too, keeping everything running smoothly so breakdowns stay rare and tools last longer without losing power. These extra steps mean customers get real value for their money spent on high end nailing systems, something that stands out in an industry where many manufacturers forget about support after the sale is done.

Future-Proofing Production with Modular Machine Designs

Scalable Solutions for Evolving Manufacturing Needs

Modular machine designs offer businesses scalable solutions that adjust to the ever-changing manufacturing landscape, helping them stay competitive in tough markets. These designs let manufacturers swap out parts or boost capacity without tearing everything apart and starting fresh, which saves money in the long run. Some research shows that switching to modular setups can slash setup time for new production lines by around 25% or more, making it easier to respond when customer needs shift suddenly. The real advantage comes from being able to adopt new tech as it emerges without breaking the bank on expensive upgrades. Many shops find this approach keeps their equipment relevant longer while avoiding those costly full replacements every few years.

Integration with Staple & Safety Pin Production Lines

Modular designs bring real flexibility to the table, making it possible to fit right into current staple and safety pin production setups while boosting overall efficiency. When manufacturers take advantage of this compatibility, they get the chance to expand their range of products without breaking the bank on major equipment overhauls. Industry reports back this approach too many companies that adopted flexible manufacturing tech saw their market presence grow by around 20% simply because they could offer a wider variety of items. What makes this so valuable is how it helps businesses stay profitable during tough times and jump on new opportunities as they arise in the marketplace.

EN

EN

AR

AR

BG

BG

CS

CS

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

LT

LT

SR

SR

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

AZ

AZ

KA

KA

BN

BN

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

KK

KK

UZ

UZ