KY Nailing Equipment: Empowering Furniture Manufacturing and Creating a New Industry Benchmark

Setting New Standards in Furniture Manufacturing Equipment

The Evolution of Industrial Fastening Technology

Fastening tech in industry has changed quite a bit over the years, especially when it comes to making furniture. Back in the day, people put together furniture using basic stuff like nails and screws. This took forever and wasn't very precise either. Then came along those mechanical fasteners, which really boosted productivity and let manufacturers create much more intricate designs. As time went on, we saw machines go from being operated manually to fully automated systems. These changes made things way faster and more accurate. Manufacturing reports show that automating these fastening processes cut down production time and saved money on labor costs too. What does this mean? More furniture gets produced consistently across the board. For companies trying to keep up with demand while maintaining quality standards, these advancements are absolutely essential.

Key Performance Metrics for Modern Nail Machines

Knowing what performance standards modern nail machines need to hit matters a lot for furniture makers. The main things people look at are how fast they work, how accurate they are, and whether they keep running without problems. These factors really determine how productive a workshop can be and the overall quality of the finished pieces. Industry groups have set some basic benchmarks too - stuff like how many nails get driven per minute, how often mistakes happen, and how consistent the results stay over time. When companies shop for new equipment, these numbers help them decide between getting something that cranks out lots of work but breaks down frequently versus machines that might be slower but last longer between repairs. Some shops saw real boosts in their workflow and fewer defects once they upgraded to newer technology. One cabinet maker reported cutting down on waste materials by almost half after switching to a better nailer, showing just how much difference good equipment can make in day to day operations.

Impact of Precision Engineering on Production Quality

When it comes to making better furniture, precision engineering makes all the difference, especially when it matters most for size accuracy and how parts fit together. Computer Numerical Control machines have become game changers in workshops across the country. These CNC systems cut wood and metal with incredible accuracy so every piece matches exactly what was designed on paper. Studies from actual factories show that when manufacturers get these measurements right, there's less wasted material lying around at the end of production runs, and customers keep their furniture longer too. For shop owners looking to cut costs while still delivering top notch work, investing in precision tools pays off big time. The industry is seeing real improvements because people simply expect better quality nowadays. Nobody wants wobbly tables or doors that don't close properly anymore. This push for perfection has actually sparked some pretty interesting innovations in how furniture gets made.

Precision-Driven Manufacturing Solutions

Advanced PLC Control Systems in Wood Fastening

Programmable Logic Controllers, or PLCs as they're commonly called, play a big role in today's wood fastening operations because they help get things done faster and better. These control systems give manufacturers instant visibility into what's happening on the production floor, which means they can tweak processes on the fly to keep everything running smoothly. When woodworkers automate repetitive jobs with PLC technology, there's less need for hands-on work, mistakes drop off, and the whole process becomes much more efficient. Take a look at some sawmills that installed these systems last year – many reported cutting down machine downtime by almost half while cranking out twice as many finished products per shift. What makes PLCs stand out is how easy they are to troubleshoot when problems arise, plus they handle all sorts of complicated setups without breaking a sweat. That's why so many shops across the country have made the switch to PLC-based automation if they want to stay competitive in this fast paced market.

Error Margin Reduction Through Automated Calibration

Calibration automation helps cut down on errors when running manufacturing equipment, which ultimately leads to better products coming off the line. The process typically relies on sophisticated software and hardware solutions that tweak machine parameters so everything stays accurate during production runs. Real world tests show pretty impressive results from companies adopting these automated systems. Take one furniture maker who saw their mistake rate drop by around 30% once they installed automated calibration tech across several production lines. Their products became much more uniform too. Industry insiders see continued improvements ahead for calibration tech, pointing out how manufacturers are already pushing boundaries with greater precision requirements and constantly raising the bar for what counts as acceptable quality standards nowadays.

Durability Enhancements in Pin Making Machinery

New developments in materials and tech have really changed how long pin making machines last these days. Manufacturers now build their equipment using better quality stuff and smarter engineering techniques. This means machines stay functional longer without needing constant repairs. Some numbers show that when companies adopt these new approaches, their pin making gear lasts about 40% longer than before. That translates to fewer breakdowns and lower repair bills over time. Most people in the industry agree that having reliable machines makes all the difference for keeping production running smoothly day after day. For factory owners looking ahead, spending money on tougher machines pays off both in avoiding unexpected stoppages and building stronger manufacturing capabilities down the road.

Best Practices in Furniture Production Automation

Optimizing Workflow with Staple Machine Integration

To enhance productivity in furniture production, the integration of staple machines into existing workflows is pivotal. Effective integration requires a strategic approach to ensure that these machines complement the production processes rather than disrupt them. Here is a step-by-step guide to integrating staple machines:

1. Assessment: Analyze current workflow to identify stages where staple machines can be effectively incorporated.

2. Selection: Choose the right staple machine based on the specific requirements and volume of production.

3. Training: Provide comprehensive training for operators to ensure efficient utilization of the machines.

4. Implementation: Install the machines and adjust the work process to incorporate their usage seamlessly.

5. Evaluation: Monitor performance and make necessary adjustments to improve output quality and efficiency.

Industry reports, such as those focusing on productivity enhancements in the furniture sector, have documented significant increases in production rates after the successful integration of these machines. The optimized workflow not only improves speed but also maintains the precision and quality of the end products.

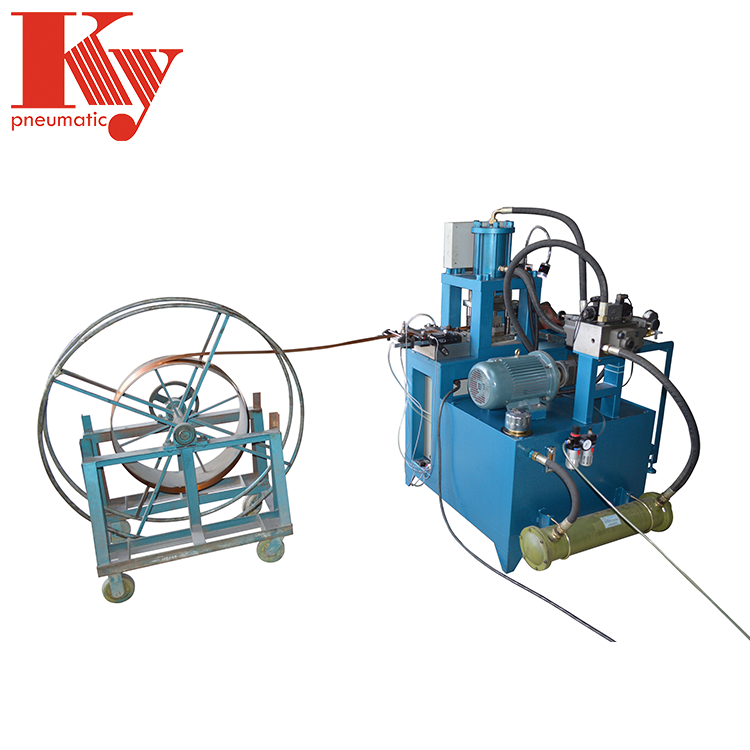

Safety Protocols for High-Speed Wire Drawing Systems

Safety is paramount when operating high-speed wire drawing machines, which are critical in furniture manufacturing. These machines possess inherent risks, requiring stringent safety protocols to protect workers and equipment. Key safety measures include:

- Conducting regular risk assessments to identify potential hazards.

- Enforcing the use of personal protective equipment (PPE) such as gloves, helmets, and eye protection.

- Implementing emergency stop mechanisms and clear warning signs to prevent accidents.

- Establishing routine maintenance checks to ensure machines operate at optimal safety levels.

Statistics highlight that where safety protocols are meticulously followed, there is a noticeable reduction in machinery-related workplace accidents. For instance, studies have recorded as much as a 30% decrease in incidents when comprehensive safety measures are in place, underscoring the importance of adherence to these protocols.

Maintenance Strategies for Wood Nail Making Equipment

Effective maintenance strategies are essential to extend the lifecycle of wood nail making machines and sustain production efficiency. A proactive approach to maintenance, distinguishing between scheduled and reactive maintenance, is key.

- Scheduled Maintenance: Regularly planned inspections and servicing can prevent unexpected breakdowns and extend machine lifespan. Tasks can include lubrication of moving parts, inspection of wear and tear, and replacement of outdated components.

- Reactive Maintenance: Responding to immediate issues as they arise can minimize downtime but should not replace scheduled maintenance. This approach is best when unexpected faults occur, requiring quick resolution to maintain production flow.

Data suggests that companies implementing regular maintenance schedules observe up to 40% higher equipment uptime. Moreover, these practices often result in significantly reduced repair costs, illustrating the long-term financial benefits of a disciplined maintenance regimen. This approach ensures equipment remains in optimal condition, supports continual production, and minimizes operational disruptions.

KY's Innovative Nail Production Systems

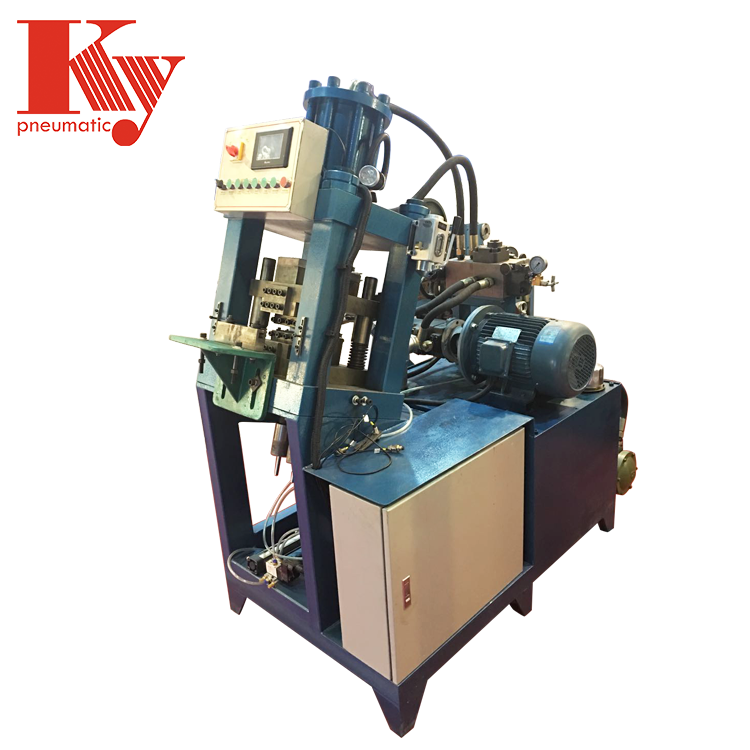

T Brad Nail Maker: Dual-Solution Flexibility

The T Brad Nail Maker stands out for its flexibility when it comes to making different kinds of nails. The system works great whether paired with just a wire band and straightener or set up with additional equipment for flattening and gluing wires. What really makes this machine special is how easy it adapts to changing production requirements. Operators appreciate the PLC controls that keep things running smoothly while they adjust speed settings between 100 to 160 nails per minute depending on demand. Factory workers who've used the T Brad report saving hours each week because their production lines run faster and with fewer interruptions. Many manufacturers now consider this nail maker essential after seeing how much time and money it saves them month after month.

F Series Machine: High-Speed Assembly Solutions

Designed for fast nail making, the F Series Machine really cranks out product at impressive speeds that boost factory output across the board. It can churn through anywhere from 100 to 160 nail rows every single minute, which makes it stand out among other assembly equipment when talking about getting things done quickly. The speed translates into real money saved too since fewer workers are needed on the line and products move through faster than traditional methods allow. Factories using these machines report seeing volumes jump while still maintaining quality standards, something that gives manufacturers a serious advantage over competitors stuck with slower, older technology.

Pneumatic Nailer: Dual-Operation Efficiency

The Auto Pneumatic Brad Nail Making Machine lets workers handle two units at once, which saves time and boosts productivity on the shop floor. Built with sophisticated pneumatic technology inside, these machines can crank out anywhere from 70 to 125 nails every minute. That kind of speed works great for folks in construction shops or furniture factories where they need lots of fasteners quickly. Many businesses that switched to this system saw their workflow get much better. One manufacturer mentioned cutting down on manual adjustments while another talked about how consistent quality has become since implementing the automated process.

T/F Hybrid System: Multi-Gauge Adaptability

The T/F Hybrid System brings real flexibility to nail production since it works with different nail sizes, which makes it great for all sorts of manufacturing needs. The ability to handle multiple gauges means factories don't have to spend time adjusting machines when orders change, something customers want more these days as they ask for customized products. With automatic controls built right in and streamlined processes across the board, this kind of system is becoming a go-to option for shops wanting to stay ahead of the curve while growing what they can actually produce.

Sustainable Manufacturing & Future Trends

Energy-Efficient Operation in Staple Production

Cutting down on energy use matters a lot for staple production if we want greener manufacturing and cheaper running costs. When factories get better at managing their power needs, they hit two birds with one stone: less harm to the environment and longer term sustainability becomes possible something that customers care about more every day. Take the new generation of pin makers and automated staple systems for instance these actually make a real difference in how much energy gets used during production runs. Many of these modern machines come equipped with features that manage electricity smarter and schedule operations when demand is lower, cutting down on wasted resources. Looking at actual numbers from the industry, companies that switch to these efficient setups typically see drops in energy bills anywhere from 15% to 30%. Beyond just saving money on the bottom line, businesses that go green this way tend to stand out in markets where being environmentally responsible isn't just nice to have anymore it's becoming expected by both clients and regulators alike.

Waste Reduction Through Smart Material Handling

Material handling methods that incorporate smart technology are changing how furniture makers approach waste reduction. Basically, these approaches combine various tech tools and workflow improvements to keep track of materials better and cut down on scraps and leftovers. When companies install things like internet connected inventory systems or automatic storage units, they tend to see fewer mistakes in stock counts and smoother operations overall. What makes these systems valuable? They help follow where materials go, give instant updates on what's available, and arrange storage spaces in smarter ways that really cut back on wasted resources. Take GB Projects for instance they slashed their waste levels dramatically after implementing these kinds of smart handling practices. The bottom line is simple: less waste means smaller environmental impact, cheaper production costs, and factories running more smoothly day to day.

Industry 4.0 Integration in Wire Processing Equipment

The principles behind Industry 4.0 are transforming how furniture makers handle wire processing equipment, bringing about smarter factory floors and better efficiency across the board. At its core, Industry 4.0 means bringing cutting edge tech like live data tracking and connected devices right into the heart of manufacturing workflows. When manufacturers start using these tools, they get a clearer picture of what's happening on the shop floor day to day. They can tweak their methods, find waste spots, and boost overall output. The Internet of Things (IoT) gives plant managers visibility into every machine and operation as it happens, which makes production lines much more adaptable when things change unexpectedly. Looking at recent numbers from the sector, there's definitely a movement toward adopting these new approaches. Factories report seeing real gains in productivity while experiencing fewer unplanned shutdowns. For companies working with wire drawing machines and wood nail making equipment specifically, getting onboard with Industry 4.0 isn't just nice to have anymore but almost essential for staying competitive. These technological upgrades not only make operations run smoother but also help reduce environmental impact over time, something that matters increasingly in today's market landscape.

EN

EN

AR

AR

BG

BG

CS

CS

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

LT

LT

SR

SR

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

AZ

AZ

KA

KA

BN

BN

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

KK

KK

UZ

UZ