From Machine Selection to After-Sales Service, KY Nailing Equipment Offers Worry-Free Support Throughout the Process

KY's Premium Nailing Machinery Solutions

T Brad Nail Making Machine: Precision Automation

The T Brad Nail Making Machine marks a real leap forward in how nails get made these days. Built to cut down on manual labor, this system boosts productivity thanks to modern tech components such as servo motors and those PLC controllers we all hear so much about. What sets it apart is how consistently it produces top notch brad nails batch after batch, something that used to be tricky with older methods. A recent study from Manufacturing Today found that factories using similar automated setups saw their output jump around 30 percent while still keeping product standards high. For small shop owners struggling to keep up with orders during peak seasons, this kind of machinery could literally change the game when trying to balance speed against quality requirements.

F Brad Nail Making Machine: High-Speed Production

The F Brad Nail Making Machine really stands out when it comes to fast production speeds while still keeping things quality-wise intact. With those high speed feeders working alongside some pretty impressive cutting tech, factories can crank out nails at lightning pace needed for big scale manufacturing jobs. Companies who actually put this machine into their workflow talk about cutting down on production time by roughly 30%, which means they get way more product rolling off the line each day and meet shipping deadlines consistently. Shop floor managers often mention how dependable these machines are during long shifts, something that matters a lot when trying to keep production lines running smoothly and stay ahead of competitors in today's nail manufacturing market.

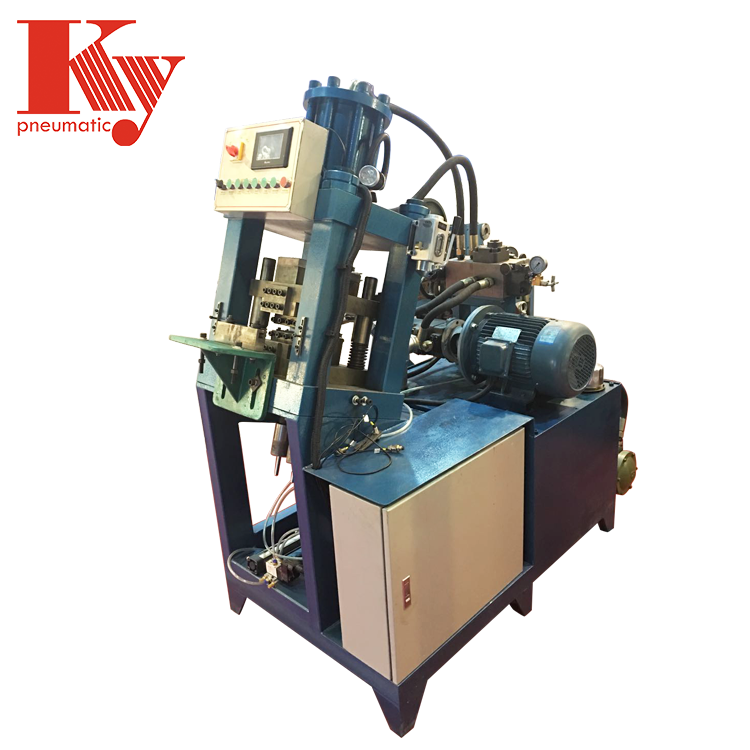

Auto Pneumatic Brad Nail Machine: Dual-Operation Efficiency

What makes the Auto Pneumatic Brad Nail Machine really special is its ability to handle multiple operations at once, giving manufacturers much needed flexibility on the shop floor. The control panel is pretty straightforward too, letting operators flip between manual mode when needed, semi-auto for those tricky jobs, and full automation for high volume runs without breaking a sweat. Most shops find they can run two machines side by side thanks to the clever design, which cuts down downtime significantly. Some field reports suggest these dual operation systems boost productivity around 40% compared to traditional setups in the nailing business, though results do vary depending on how well trained the staff happens to be.

T/F Series Multi-Gauge Nail Machine: Versatile Manufacturing

The T/F Series Multi-Gauge Nail Machine stands out because it can handle all sorts of nail sizes during production runs, which meets many different factory requirements. What really helps here are the built-in features that let workers switch between gauges quickly without much hassle, cutting down on wasted time when changing production lines. Looking at how things work in real factories, machines like the T/F Series give manufacturers options they otherwise wouldn't have. This means companies can offer more types of products to customers, giving them an edge against competitors who stick to one size fits all approaches. Construction sites need nails of various thicknesses depending on what they're building, while furniture makers often require specialized fasteners too. By getting the T/F Series on board, shops stay flexible enough to tackle these varied orders without constantly investing in new equipment just for occasional jobs.

Comprehensive Nailing Equipment Support Services

24/7 Technical Assistance & Remote Diagnostics

Round the clock tech support makes all the difference when it comes to keeping nailing equipment running smoothly and cutting down on those frustrating stoppages. When businesses get help anytime day or night, they can fix machine problems fast before things spiral out of control and mess up entire production schedules. Remote diagnostics really shine here too since technicians can spot issues from afar and sometimes fix them entirely without ever setting foot onsite. The wait time drops dramatically compared to traditional methods, which means machines stay productive longer. Customer feedback shows pretty clearly that companies using these 24/7 support systems plus remote troubleshooting see their downtime drop by quite a bit. Makes sense really, because nobody wants their workflow constantly interrupted by equipment failures.

On-Site Machine Installation & Calibration

Getting nailing machines properly installed and calibrated at the worksite makes all the difference when it comes to how well they perform. When setting these machines up, workers need to configure them correctly based on what the business actually needs and how the factory space looks. This kind of setup ensures everything runs smoothly right from day one. Most manufacturers also offer calibration services that adjust machine settings precisely so they match production demands and maintain quality throughout operations. Industry data shows time and again that skipping these initial steps leads to problems down the road. Taking care with installation isn't just good practice it directly affects whether those machines will keep working reliably year after year without constant breakdowns or inaccurate results.

Preventive Maintenance Programs

Regular maintenance routines make all the difference when it comes to keeping nailing guns and other fastening equipment running strong for years instead of months. Most good maintenance plans include things like checking air pressure settings, lubricating moving parts, and inspecting for worn components at set intervals throughout the work week. Catching small issues early stops them from turning into major breakdowns during critical jobs. Real world data shows businesses that stick with regular maintenance end up spending way less money fixing broken tools down the road than shops that wait until something breaks before doing anything about it. Equipment that gets proper care lasts longer obviously, but there's another bonus too: consistent tool performance means workers don't waste time troubleshooting problems, so overall shop productivity actually goes up while repair bills go down.

PLC-Controlled Operation for Error Reduction

The manufacturing sector has seen major improvements in reliability and fewer mistakes in nail production since PLC (Programmable Logic Controller) systems became widespread. These controllers act like the central nervous system for automated machines, constantly checking what's happening and making quick fixes when something goes wrong. For instance, if a machine starts producing nails that are too short or long, the PLC catches this issue almost instantly and adjusts accordingly. According to a recent study from Manufacturing Tomorrow, companies using these systems experience smoother operations and better accuracy across their production runs. What makes PLCs so valuable is their ability to make those split-second corrections, which keeps quality consistent and prevents expensive shutdowns on the factory floor.

Automatic Lubrication & Mold Protection

Automatic lubrication systems along with mold protection tech are changing how maintenance works in the nail manufacturing business. When machines get regular lubrication, the moving parts don't wear down as fast, which means less time spent on repairs and maintenance. The mold protection part is just as important because it keeps the nails looking good and functioning properly throughout production runs. Without proper mold care, products can end up warped or damaged. A recent report from last year showed factories using this kind of equipment experienced around 30 percent fewer maintenance issues overall. Beyond just extending machine life, these improvements help keep production running smoothly without unexpected stops, making operations run better day after day.

Safety Protocols for Staple Making Machinery

Keeping workers safe remains a top priority when operating staple making machines. The KY equipment comes with several built in safety features meant to keep operators out of harm's way. We've got things like guard covers, big red emergency stops, and those fancy monitoring systems that watch what's going on in real time. All this helps meet those tough safety regulations that govern how machinery should run. A report from NIOSH showed that companies who put serious effort into safety saw around 40 percent fewer accidents across the board in their factories. Beyond just protecting people though, these safety measures actually help boost productivity too since they prevent shutdowns caused by incidents or maintenance issues down the line.

End-to-End Service Benefits for Manufacturers

Minimized Downtime with Rapid Response Teams

Rapid response teams represent a smart way to cut down on production stoppages across manufacturing facilities. These specialized groups get trained specifically to tackle equipment breakdowns fast so problems don't linger too long. When looking at how well things run day to day, numbers like how quickly they respond and how much time machines stay running matter a lot. Take this example: cutting downtime by around 30% means factories produce more goods without extra costs. Real world feedback backs this up too. A factory manager shared that after bringing in their own quick reaction team, they saw almost double the normal operating hours each week. That kind of improvement makes all the difference when competing against other manufacturers trying to squeeze every last minute out of their production lines.

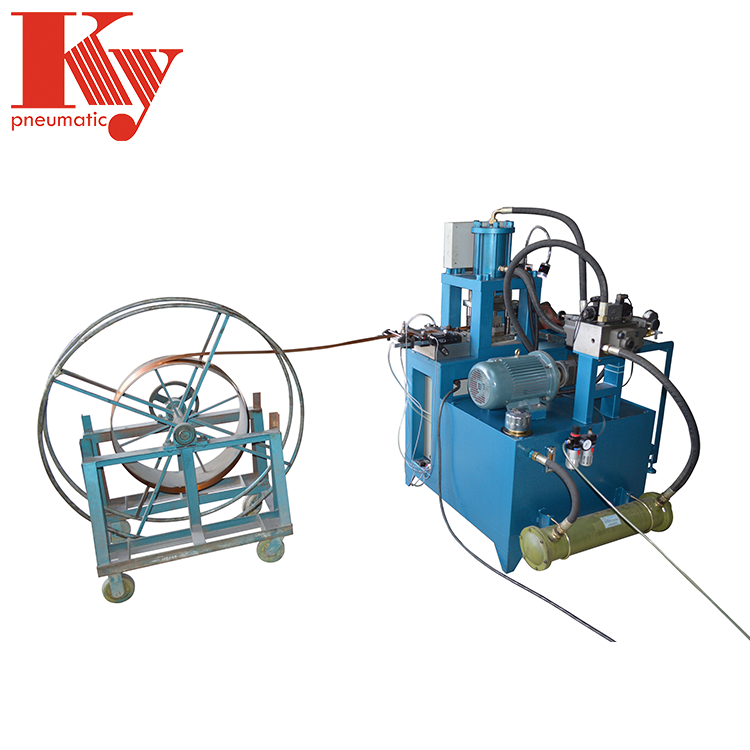

Customizable Wire Drawing Machine Integration

Wire drawing machines that can be customized give manufacturers exactly what they need for their particular production needs, and they work pretty well with whatever equipment is already on site. What makes these machines so valuable is that they can grow with a business or change when production priorities shift. Take a company wanting to switch gears and start making something completely different - these machines let them tweak settings instead of shutting everything down for days or spending big bucks on new equipment. We actually saw this happen at one factory where they modified their wire drawing setup and ended up cutting processing time noticeably, maybe around 20 or 25 percent? Not sure about the exact number but everyone noticed better quality wires coming out and way less scrap material going to waste. Bottom line, having adaptable machinery means staying ahead of competitors without constantly chasing after the latest trends in manufacturing.

Lifetime Cost Savings Through Proactive Care

Looking after machinery before problems arise pays off big time financially, mainly because it cuts down on those costly repair bills and replacement parts over time. Regular check-ups and maintenance keep everything running smoothly while preventing those nasty surprise breakdowns that disrupt production. Many factories now use digital dashboards and tracking software to monitor how well their machines are performing and where money is being spent. Some studies show businesses that stick to good maintenance routines can cut their repair costs by around 20% within just five years, which makes a real difference in their profits. Beyond saving money upfront, taking care of equipment means machines last longer overall, and that translates directly into better margins for manufacturing operations.

EN

EN

AR

AR

BG

BG

CS

CS

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

LT

LT

SR

SR

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

AZ

AZ

KA

KA

BN

BN

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

KK

KK

UZ

UZ