Global market trend of Ky Nailing equipment

Introduction to Ky Nailing Equipment

The Ky Nailing Equipment sector around the world is growing pretty fast right now. Industry insiders point to increasing demand because these tools have become so important in today's manufacturing setups. Market analysts estimate that we're looking at roughly 5% annual growth for this segment in coming years. Why? Well, manufacturers are turning to these nailing systems more and more as they need faster production lines and better quality control. The machines automate what used to take hours of manual labor, making factories run smoother while cutting down on errors. For companies dealing with large scale wood products or metal fabrication projects, having reliable Ky nailers makes all the difference between meeting deadlines and falling behind schedule.

Ky Nailing Equipment plays a major role in today's manufacturing landscape, boosting both efficiency and productivity across multiple sectors. The machines handle complex jobs with remarkable accuracy, cutting down on the need for manual labor while also slashing the chances of mistakes happening during production runs. When manufacturers incorporate features such as PLC control systems into their operations, they see real improvements in how fast things get done and how dependable the results are. That's why these nailing solutions have become so popular in woodworking shops, construction sites, and furniture factories where consistent quality matters most.

Key Features of Ky Nailing Equipment

Ky Nailing Equipment stands out because it integrates cutting edge tech and automated functions that really boost accuracy during production runs. The newer machines come equipped with these fancy PLC control systems instead of old school relays, making them work quicker and more dependable overall. What makes these systems so good? They deliver pinpoint accuracy when automating tasks, cutting down on mistakes made by people and keeping products looking consistent across the board. Take nailing operations for example the machines can hit exactly the same spot every single time, so there's way fewer defective items coming off the line. This means manufacturers save money on waste while still delivering better quality goods to customers.

The production efficiency of Ky Nailing Equipment stands out quite a bit when we look at how it stacks up against older manufacturing approaches. The machines come packed with automated features and cutting edge tech that really boosts production numbers beyond what most competitors can achieve. Traditional manufacturing still struggles with inefficiencies because workers need to manually handle so many parts of the process, plus things just take longer overall. Ky's equipment changes all that by making the whole workflow much smoother. Factories using these systems see their output go way up while each product takes less time to complete. For businesses, this means they get more done in less time, which translates to faster turnaround for customers and gives them an advantage over rivals who haven't made the switch yet.

Exploring the Uses of Ky Nailing Equipment

Ky Nailing Equipment plays an important part in all sorts of industries including furniture making, building projects, and package handling. When making furniture, this gear helps put together frames and attach fabric covers so pieces last longer and look better overall. For construction work, contractors rely heavily on these tools during roof installation and wall framing jobs because they speed things up without compromising how strong everything stays. Packaging companies also find value in using them to close up large boxes and wooden crates securely before shipping products anywhere. Looking at how widely applicable this equipment really is across different sectors shows just how versatile and essential it has become throughout various manufacturing operations.

Ky Nailing Equipment brings real value to manufacturing floors across various industries. For starters, these machines cut down on labor expenses since they automate most of what would otherwise require hands-on work from workers. The precision built into these systems means products come out consistently well made without those annoying little defects that happen when nails aren't placed correctly. What really stands out though is how much faster everything gets done. Some facilities report cutting production times in half after installing this equipment. When businesses integrate Ky Nailers into their workflow, they typically see better bottom lines from reduced waste, higher customer satisfaction rates due to improved product quality, and the ability to handle bigger orders without breaking a sweat.

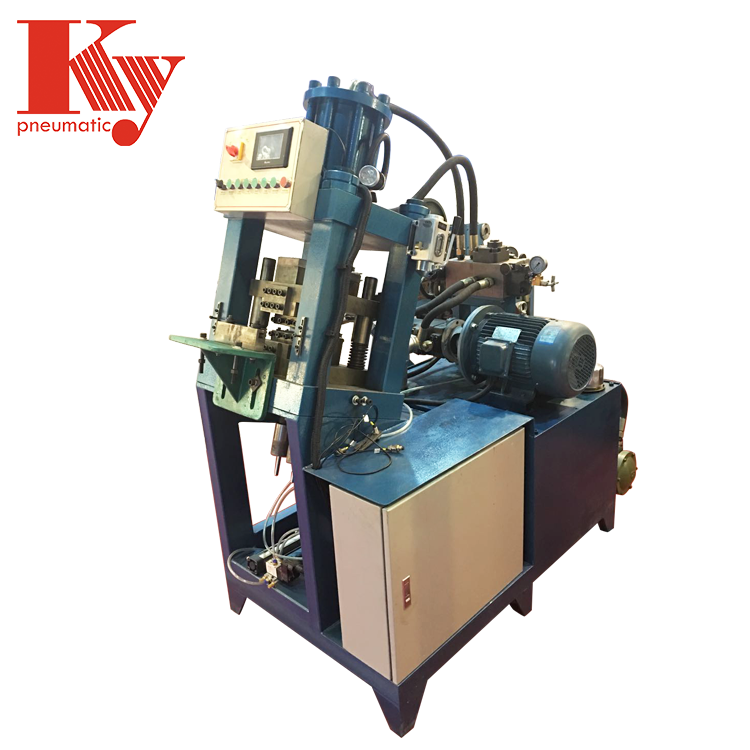

Product Spotlight: Auto Pneumatic Brad Nail Making Machine

What really sets the Auto Pneumatic Brad Nail Making Machine apart is not just looks but how well it actually works on the factory floor. One of its biggest selling points? The ability to run two machines at once! A single worker can handle both units without breaking a sweat, which means factories get twice as much done while spending half as much on staff. Inside this beast sits some pretty impressive technology too – those PLC controls let operators switch between different modes depending on what they need at any given moment. Want full automation? Got it. Need more hands-on control? That's covered too. And let's talk about accuracy here folks. We're talking 0.1mm tolerance levels when adjusting nail lengths. That kind of precision means no more rejects from inconsistent sizing, so each shipment goes out looking spot on perfect.

This machine stands out in the marketplace because it gets things done fast without breaking the bank. The production rate ranges from around 70 up to 125 nails each minute, and still meets all the quality requirements across different manufacturing sectors. What really makes operators happy are the smart auto-lube system that keeps everything running smoothly and those multiple safety layers built right in. We're talking about protections against current overloads and other hazards that keep workers safe day after day. All these tech upgrades mean fewer interruptions when something goes wrong and longer life between replacements, which is why so many factories have made the switch to this model over competitors on the shelf.

Future Trends in Ky Nailing Equipment

The world of Ky Nailing Equipment is changing fast these days thanks to new tech developments, especially around smart features and custom builds. Smart tech like IoT devices is really transforming how these machines work on shop floors, making them easier to handle while getting things done faster. Take a look at what's happening now: many machines come with built-in sensors that keep track of how they're performing and even warn operators when parts might need replacing before breakdowns happen. This cuts down on wasted time waiting for repairs. Meanwhile, customization isn't just a buzzword anymore either. Shops across the country are finding ways to tweak their equipment setups so they fit exactly what their particular workflow demands. Some manufacturers offer modular components that let businesses mix and match parts depending on daily production needs, which ultimately means better results without all the extra hassle.

The push for greener practices is reshaping how Ky Nailing Equipment gets made across the manufacturing sector. With governments tightening rules on emissions and customers wanting greener options, plant managers are scrambling to cut down on carbon output. Many factories have started swapping out traditional materials for ones that can be recycled later, while others install new tech that eats up less electricity during production runs. Some forward thinking companies even set up systems where scrap metal from one part of the process gets reused elsewhere in manufacturing, cutting down on waste mountains. Beyond simply following the law books though, going green actually makes good business sense too. Consumers notice when brands walk the talk on sustainability, which helps build trust and loyalty over time as we all try to meet those lofty international climate targets.

Conclusion: The Growth Potential of Ky Nailing Equipment

Innovation is the driving force behind the growth of the Ky Nailing Equipment sector. Recapping the highlighted market trends, we see that adopting smart technology and enhancing product customization are vital for staying competitive. Businesses must leverage these advancements to optimize their operations and increase productivity.

Businesses need to keep up with what's happening in their industry if they want to really get value from Ky Nailing Equipment. Experts in the field keep pointing out that keeping tabs on new tech developments and regulatory updates matters a lot. When companies stay on top of these things, they avoid getting caught off guard by rules changes. Plus, being ahead of the curve means they can lead in innovation instead of following others. Many manufacturers have seen real benefits when they adapt quickly to market shifts, often finding themselves positioned for better growth opportunities down the road.

FAQ

What is Ky Nailing Equipment?

Ky Nailing Equipment is advanced machinery used in manufacturing to improve efficiency and precision, reducing manual effort and minimizing errors.

In which industries is Ky Nailing Equipment commonly used?

It is commonly used in furniture manufacturing, construction, and packaging industries for tasks like assembling frames, roofing, and sealing boxes.

What are the key features of Ky Nailing Equipment?

Key features include advanced PLC control systems, precision in automation, increased production efficiency, and reduced cycle times.

What is the Auto Pneumatic Brad Nail Making Machine known for?

This machine is known for its dual-operation capability, advanced PLC control systems, and ability to produce 70-125 nails per minute efficiently.

What are the future trends in Ky Nailing Equipment?

Future trends include the integration of smart technology like IoT, increased customization options, and a focus on sustainability and eco-friendly manufacturing processes.

EN

EN

AR

AR

BG

BG

CS

CS

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

LT

LT

SR

SR

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

AZ

AZ

KA

KA

BN

BN

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

KK

KK

UZ

UZ