Material selection of staples: from low carbon steel to high carbon steel

Understanding Material Selection for Staples: Low Carbon vs High Carbon Steel

Picking out materials matters a lot when it comes to manufacturing, particularly when making those little staples we see everywhere from office supplies to medical devices. Getting this right means the finished item actually works as expected, lasts longer than it should, and does what it was made for without failing at inconvenient moments. When talking specifically about staples, manufacturers need to look at things such as how strong the metal is versus what it costs to produce them. These considerations really affect whether or not the staple holds together under pressure or just bends over time. Some companies might prioritize durability even if it means spending extra on better quality steel, while others balance budget constraints against basic performance requirements.

Carbon steel remains popular for staple production because of all the different ways it can be worked with. Take low carbon steel for instance. People love working with this stuff since it bends so easily without needing any special heating processes. Manufacturers find it particularly useful when they need to create staples that will go through bending operations or get pulled into various shapes during production runs. The material just doesn't break down under these conditions while keeping costs reasonable too. On the flip side, when we talk about high carbon steel, what we're really looking at is something much tougher and harder wearing. This type works best in situations where things might get rough on the staples over time. Think industrial settings where staples have to hold up against constant stress and friction without breaking apart or losing their grip.

Understanding the differences between low carbon and high carbon steel allows manufacturers to produce staples best suited for various tasks, from everyday office use to industrial applications requiring robust performance.

Low Carbon Steel: Characteristics and Applications

Low carbon steel isn't known for being super strong but scores high points when it comes to working with it. It bends well, cuts easily, and welds without much trouble. With carbon levels below 0.25%, this type of steel really shines when shaping into different forms, which explains why manufacturers rely on it across many industries. Standards bodies have long recognized ASTM A36 as a benchmark for these steels, particularly useful where components don't need special heat treatments. What makes low carbon steel stand out? Well, how it behaves depends quite a bit on things like how it was originally tempered, what shape the final part needs to be, and how much cold working happens during production. All these characteristics make it perfect for projects where lots of reshaping is required throughout the manufacturing process.

Low carbon steel plays a big role in staple manufacturing across various applications. What makes it work so well? Mainly because it cuts easily on machines and forms nicely when shaped, which is why it ends up in staple pins and wires all over the place. When making those thin wires needed for staples, the steel gets drawn through tiny holes called dies. This stretches the wire longer while making it thinner at the same time, and it's basically how most staple machines operate today. Another thing that matters a lot is how the steel holds up when bent repeatedly. Staple pins need to survive thousands of bends without snapping, something regular steel just can't handle. That's why factories stick with low carbon variants even though they might cost a bit more upfront. The result? Staples that won't break when closing documents but still snap off cleanly once inserted properly.

High Carbon Steel: Strength and Durability

Carbon steel with high carbon content stands out because it's much harder, stronger, and resistant to wear than regular low carbon steel varieties. Most industry specs say these high carbon grades usually have around 0.6 to 1 percent carbon in them. The extra carbon means this type of steel can be heat treated to achieve really good hardness levels while maintaining durability. What makes high carbon steel so special is how well it holds up against wear and tear over time. That's why manufacturers rely on it for things like cutting tools, springs, and other parts that need to last through heavy use without failing when reliability matters most.

High carbon steel stands out because of how tough it really is, which explains why it works so well in tough situations across construction sites and manufacturing plants where things need to hold up under pressure. People commonly use this material to make all sorts of stuff like those super strong staples that won't bend easily, sharp cutting instruments, durable springs, and top quality kitchen knives that last forever. What makes high carbon steel special is that it can take a beating without bending or breaking, making it perfect when both power and lasting performance matter most. Construction crews rely on this metal for building parts that support weight and for making specialized gear meant to function even when conditions get rough around job sites.

Comparative Analysis: Low Carbon vs High Carbon Steel

Understanding the differences between low and high carbon steel can greatly influence material selection in staple manufacturing. Here's a structured comparison of their mechanical properties.

Yield Strength

Low Carbon Steel: Typically ranges from 300-500 MPa.

High Carbon Steel: Usually exceeds 600 MPa, providing superior load-bearing capacity.

Elongation

Low Carbon Steel: Possesses higher elongation around 15-25%, indicating better ductility.

High Carbon Steel: Has reduced elongation of about 5-10%, making it less ductile but more rigid.

Hardness

Low Carbon Steel: Softer with a hardness level that allows for easy machining and forming.

High Carbon Steel: Much harder, which enhances durability and wear resistance.

Each type of steel displays varying strengths suitable for different manufacturing uses.

Choosing the right type of steel matters a lot when manufacturing staples. For mass production runs, low carbon steel works really well because it bends easily and doesn't break the bank. Manufacturers love working with this material since it can take all sorts of shaping during processes such as wire drawing and welding operations that happen regularly on staple production lines. The stuff holds up pretty good under normal conditions too, so staples made from it tend to last longer before breaking down in everyday use. That said, if the application involves heavy stress or constant friction, other materials might be worth considering despite the extra cost involved.

High carbon steel works best when making heavy duty staples that need extra strength and hardness. Not so great for places where things need to bend or flex a lot though since it tends to crack if bent too much. The real advantage comes from its strong tensile strength and ability to resist wear, which is why manufacturers often pick it for staples that face high pressure or require solid mechanical support. When picking between materials, factors like what kind of stress the staple will encounter day to day and how much force needs to be handled really matter in the decision process.

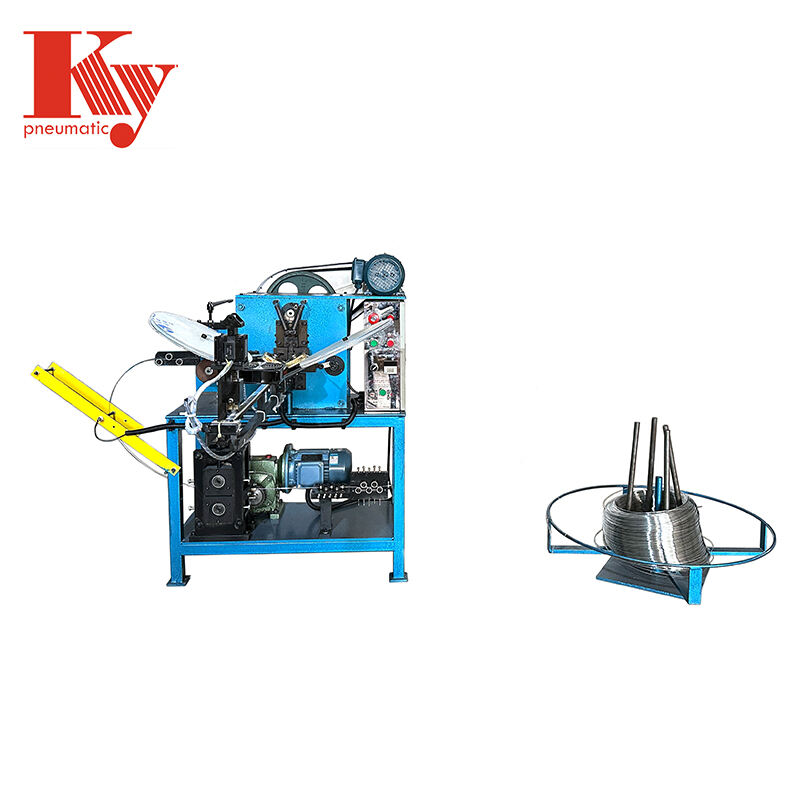

The Role of Technology in Staple Production

Recent improvements in staple making tech have made factories run smoother while wasting less material overall. Take the Fine Wire Staple Maker as an example. It runs on a high pressure oil system paired with computer controls that keep things quiet and breakdowns to a minimum. What really stands out is how this machine sorts staples all by itself, which means fewer workers need to handle them manually and factory expenses drop accordingly. The best part? It swaps out those old heavy punch presses for a hydraulic setup instead. Not only does this make operations safer and steadier, but it also speeds things up considerably compared to what was possible before.

Machines such as the HR22 D Ring Staple Machine and the Highly Automated Staple Production Line are changing how things get made in factories across the country. The HR22 runs quietly and stays stable during operation, making it great for companies producing items like pet cages and wooden furniture components. What really stands out is its built-in counter that tracks staples produced and a straightening mechanism that keeps everything aligned properly. For larger operations, the Highly Automated line brings real benefits too. It uses electromagnetic heating technology which not only makes the whole process safer but also cuts down on electricity usage significantly. Some manufacturers report saving around three quarters of their previous energy costs after switching to this system.

Staple making machines equipped with servo feeding systems have become essential for automating the feeding process in many factories. These machines actually make things more precise while cutting down on what companies spend to run operations day to day. They consume relatively little electricity compared to older models and maintain consistent feeding lengths throughout production runs, which means fewer defects in the final products. Most modern units come with touch screen interfaces that let operators tweak settings quickly without needing special training. This makes adjustments much faster when conditions change during manufacturing. The improvements we've seen in recent years translate into real money saved for businesses, less reliance on manual labor, and overall better output from staple manufacturing lines across different industries.

EN

EN

AR

AR

BG

BG

CS

CS

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

LT

LT

SR

SR

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

AZ

AZ

KA

KA

BN

BN

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

KK

KK

UZ

UZ