Maintenance and care of staplers: extend the service life of equipment

Understanding Your Stapler's Components

A typical stapler comprises several essential components, each playing a crucial role in its functionality. Understanding these parts can enhance your ability to troubleshoot and maintain your stapler. The main parts of a stapler include:

Base: This provides stability and support for the stapler. In manufacturing standards, the base is designed to resist impact and distribute pressure evenly during use.

Handle: Operating as a lever, it is designed to transmit the force exerted by the user to drive the staple through the paper.

Die or Staple Channel: A metal piece that shapes and positions the staple for insertion. According to educational resources on stapler mechanics, this component ensures the proper alignment of the staple.

Anvil: Positioned at the base, it clinches (or bends) the staple ends after driving them through the material, a critical function for securing papers tightly.

Staple Magazine: This is where staples are loaded. A well-functioning staple magazine ensures a smooth and consistent staple feeding process.

Every part plays a role in how well a stapler functions. Pressing down on the handle sets off a chain reaction involving the die and anvil working together. Get this right and the stapler will give consistent good results time after time. Knowing how things actually work makes all the difference for keeping the device running smoothly. Take the staple magazine for instance it pairs up with the die to reduce those annoying jams we've all experienced. A little regular maintenance goes a long way too. Clean out debris regularly and make sure staples are loaded properly to avoid most problems. Anyone who wants their stapler to last should understand what each basic component does and why it matters.

General Maintenance Practices for Staplers

Keeping a stapler working well for years means giving it some regular cleanings now and then. Start by getting rid of all the junk and dust stuck in there with something like a tiny brush or even an old toothbrush works great for knocking loose those pesky bits hiding deep inside. Next step? Grab a can of compressed air and blast away any fine dust that's managed to sneak into those tricky spots nobody ever sees. Don't forget to run a slightly damp cloth over the outside too so grime doesn't build up over time. Just remember not to go overboard with water though because too much moisture will only lead to rust problems down the road and nobody wants their trusty stapler turning into a puddle on their desk.

Getting the staples loaded right matters a lot for keeping things running smoothly. When staples aren't loaded properly, all sorts of issues pop up including constant jamming and alignment problems that nobody wants. Before putting any staples in, check what kind of staples work best with your particular stapler model according to the manufacturer guidelines. Most people skip this step but it really does make a difference in how well everything functions without those annoying misfires. Don't go overboard with the number of staples either. Stuffing too many into the chamber creates extra pressure inside which not only leads to more misfires but might actually break some internal parts over time. We've seen plenty of staplers ruined simply because someone tried to cram in way too much at once.

Finally, regular inspection of the staple magazine is essential. Look for any obstructions that might prevent staples from feeding correctly. Routine checks along with these maintenance practices, informed by expert guidance, will help maintain the reliability and efficiency of your stapling machine.

How to Maintain Staplers for Longevity

Maintaining staplers effectively ensures their longevity and smooth operation. For long-term non-usage care, it is essential to store staplers in a dry environment to prevent rust or moisture damage. Ensure that staples are removed before storage to avoid tension on the spring mechanism that can weaken over time.

When it comes to keeping things running well in the short term, checking for signs of wear makes all the difference. Look at those moving parts now and then, maybe once a month or so, and give hinges and springs a quick shot of machine oil. Just enough to keep everything sliding without resistance. But don't go overboard with the oiling thing either. Too much lubricant actually attracts dirt and grime that gets stuck in there, causing problems down the road. Most people find that sticking to this simple routine adds years to their stapler's lifespan while keeping it working properly through daily office tasks.

Common Issues and Solutions for Stapler Maintenance

Office staplers get used all day long but tend to jam pretty frequently. This happens mostly because staples aren't lined up right, get bent during insertion, or something gets stuck inside the mechanism. When this happens, first thing to do is pop open the stapler and look around for anything blocking the way. Grab those needle nose pliers and gently pull out whatever's caught there without breaking anything else. Also worth mentioning is making sure the staples actually fit the stapler model being used since people sometimes grab the wrong size by accident. Regular cleaning goes a long way too. Just wipe out dust and bits of paper that accumulate over time, which keeps the stapler working smoothly instead of getting stuck every other day.

One common problem people run into is when their stapler shoots out several staples at once instead of just one. Usually this happens because the staples aren't lined up right in the magazine, some internal parts have gotten worn down over time, or someone jammed too many staples into the chamber. Start by looking at how the staples sit in the magazine and make sure they're all straight and not bent. Take a peek inside at the spring mechanism too since those tend to get tired after years of use. If anything looks damaged or stretched out, it's probably time for a replacement part. Also important: don't stuff the magazine full to the brim. Leave some space so there's no extra pressure building up inside. These simple fixes should stop the annoying habit of double (or triple!) stapling, getting your office supply back to normal operation.

Staplers tend to misfire or jam all the time, especially when there's gunk stuck in the hammer part or when using staples that are just too long for what we're trying to staple. First thing to do? Check around the hammer area for anything blocking it up. A little brush works great, or sometimes blowing compressed air through there helps clear things out. Still having trouble after cleaning? Maybe the problem lies in the staples themselves. Standard office supply stores carry different lengths, so grab ones that actually fit what our stapler was designed for. Regular cleaning plus picking the right staples goes a long way toward keeping those annoying jams at bay and making sure our trusty stapler keeps working properly day after day.

Product Recommendations for Stapler Maintenance

For effective stapler maintenance and enhanced performance longevity, several high-quality machines are available that cater to various stapler types and applications:

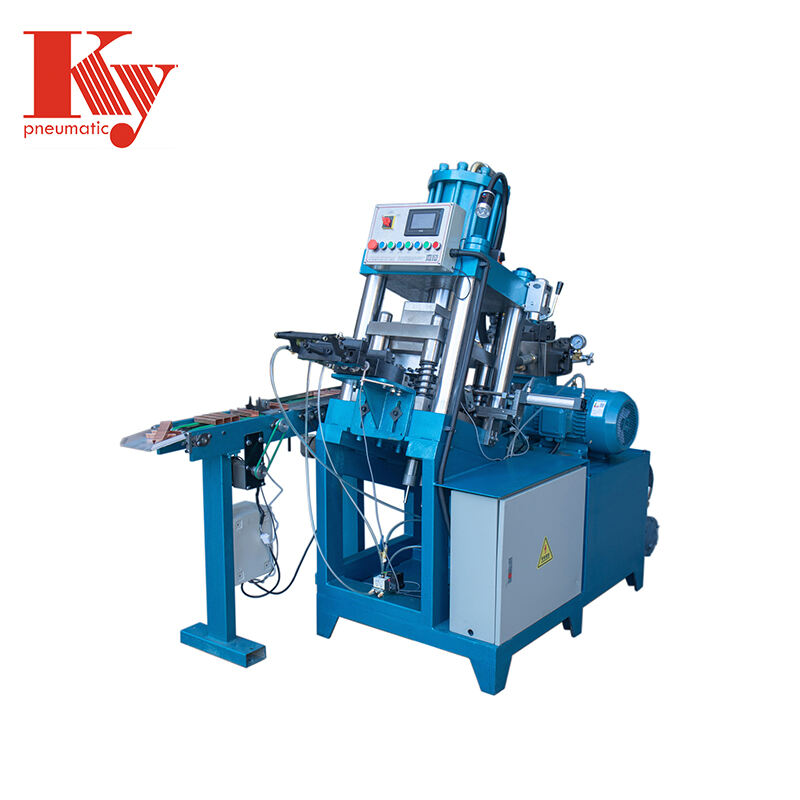

32/35/34 Carton Closing Staple Making Machine

This machine excels in pressing and forming wire bands into final product staples with hydrodynamic operations, offering stable performance and low noise output. Its ability to adjust the length of nails enhances its flexibility for diverse applications.

Mattress Clip Staple Making Machine

Incorporating advanced international manufacturing techniques, this machine minimizes energy consumption while maximizing stability and speed, essential for efficient stapler production and maintenance.

These machines significantly contribute to maintaining and improving stapler performance, thereby boosting overall productivity. Their features ensure efficient operations tailored to specific industrial needs.

EN

EN

AR

AR

BG

BG

CS

CS

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

LT

LT

SR

SR

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

AZ

AZ

KA

KA

BN

BN

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

KK

KK

UZ

UZ