Wire processing in metal processing: from wire drawing to forming

Understanding Wire Processing Techniques in Metal Forming

Wire processing plays a big role in metal forming, basically turning raw wire stock into all sorts of useful shapes and parts. The process usually starts with wire drawing, where manufacturers pull the wire through multiple dies to get it down to the right size. After that comes straightening out any kinks so everything lines up properly for what's next. When it comes to bending and shaping, special jigs and dies help create those exact angles needed for things like coil springs or hook attachments. There's also flattening operations, piercing holes, and even more complicated stuff like adding threads or making drilled features. These advanced steps let manufacturers produce really detailed components that fit specific industry standards and specifications across different applications.

Wire processing has come a long way in the last few years thanks to better tech that makes things more accurate and efficient. These days, manufacturers are using CNC machines along with camless wire benders to shape wires into all sorts of complicated 3D shapes while wasting almost no material. Parts produced this way fit their specs exactly, which means fewer rejects on the production line. The automotive sector sees big gains here, as do companies making small electronic components. For instance, car makers can now create intricate frame structures that were once impossible, while phone manufacturers get thinner, lighter connectors. This kind of progress keeps opening doors for new designs across metalworking fields.

Key Wire Processing Techniques in Metal Forming

Wire Drawing

Wire drawing remains one of the core methods in metal shaping processes. Basically, it works by pulling metal stock through progressively smaller dies to shrink down the wire diameter. What makes this method so valuable isn't just the size reduction but actually how it strengthens the material at the same time. According to some industry data from the Metal Forming Institute, we're talking about roughly a 50% boost in tensile strength after proper wire drawing. The resulting thin wires find their way into all sorts of places these days. Electronics manufacturers rely on them for delicate circuitry components. Medical device companies need them for surgical instruments and implants. Even telecom providers depend on these strengthened wires for their fiber optic cables since they simply won't work without that extra durability built right in during production.

Flattening

Flattening stands out as one important method in wire processing where manufacturers press the round wire down into flat strips instead. When wires get flattened like this, they become much more useful across different manufacturing scenarios, especially when making all sorts of electrical parts and mechanical bits. The industries that work with these flattened wires report around a 30% boost in their production speed because there's just so many ways to apply those flat strips throughout the factory floor. Take the automotive industry for instance. Car makers rely heavily on flattened wires for things like battery connections and grounding systems since the flat shape gives better contact over larger surfaces compared to regular round wires.

Bending and Shaping

Wire processing involves various bending and shaping techniques including forming and coiling. These approaches allow production of specialized items like springs, hooks, and other complex components. What makes these methods so valuable is their capacity to adapt to almost any design requirement. Manufacturers can actually craft parts with all sorts of angles and curves that would be impossible through standard manufacturing methods. Take aerospace engineering for instance where precision matters most. The same applies to automotive industries needing custom suspension components. Modern wire forming equipment has really advanced over recent years, giving producers unprecedented control over final product shapes while maintaining strict quality standards across different applications.

Each of these wire processing techniques serves a distinct purpose within the metal forming industry, contributing significantly to producing wire-based components required across various industries. Together, they exemplify the technological advances that continue to improve production efficiency and product quality in wire manufacturing.

Applications of Wire Processing in Various Industries

Wire processing plays a really important part in car manufacturing, especially when making things like electrical cables, connection points, and structural reinforcements. When manufacturers integrate better wire processing methods into their workflows, they actually get stronger parts that last longer without failing. Looking at numbers gives us another perspective on why this matters so much for the industry. Market research suggests that demand for automotive wiring products will hit around 15 billion dollars worldwide by mid-decade. That kind of growth shows just how dependent modern vehicle production has become on sophisticated wire handling technologies across different manufacturing stages.

Precision matters a lot when it comes to wire processing techniques in medicine, especially for making things like surgical staples and important parts of medical instruments. Without getting these right, doctors can't perform procedures safely or effectively. We've seen a big jump in demand for quality medical gear that depends on good wire work. The market has grown about 25% recently. That kind of growth shows just how important it is to get wire processing right in healthcare settings if we want to keep patients safe and treatment outcomes good across the board.

Home appliances, electronics, and countless other consumer goods rely on wire processing to make essential parts like coils and structural frames. Wire processing is pretty versatile actually, letting manufacturers create components that are both light weight and tough enough to last. We're seeing more and more wire being used across these product categories lately. The market keeps asking for better solutions that work well over time, and wire just happens to fit the bill. Looking at how consumers want their gadgets and appliances to perform reliably day after day, it becomes clear why wire processing remains so important in delivering those quality standards people expect from their purchases.

Innovative Machinery for Wire Processing

Recent improvements in wire processing machines have really changed how efficiently factories operate and how precise their work is. Take the Fine Wire Staple Maker as just one good example. These automated machines crank out staples at incredible speeds while cutting down on wasted materials something that matters a lot in today's manufacturing world where staple production runs constantly. With PLC control systems built right in, operators can switch between different production settings manual, semi-auto, or fully automatic depending on what the job needs. That flexibility makes these machines essential for any business looking to maximize output while keeping those pesky errors to a minimum.

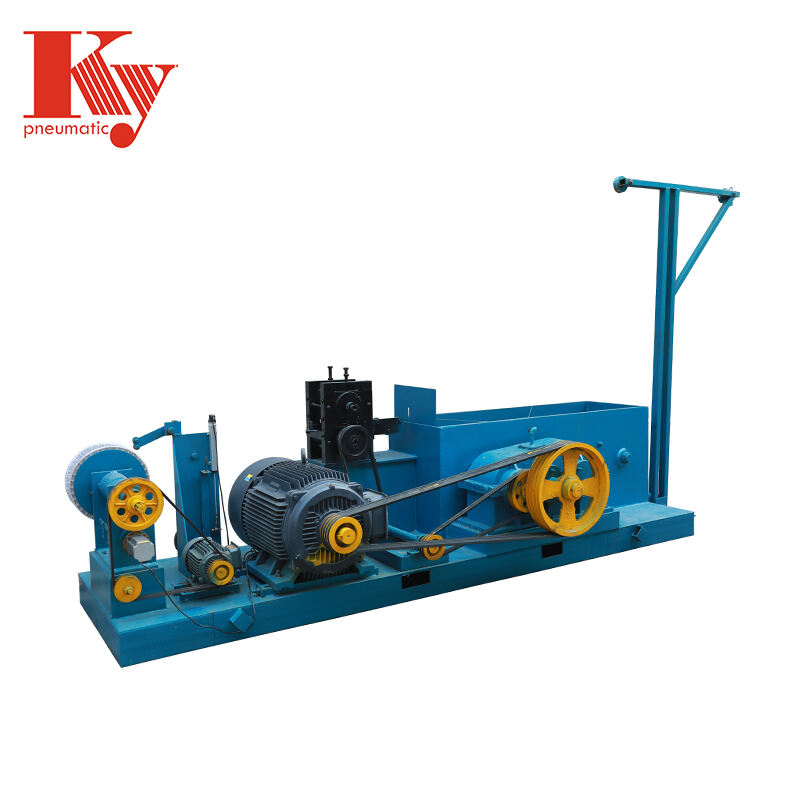

The Wire Drawing and Flattening Machine stands out as a game changer in the industry, combining what were once separate processes into one efficient operation. Manufacturers can draw and flatten wires simultaneously, cutting down on production time significantly. This kind of machinery handles all sorts of wire specs from thin gauge materials to thicker industrial grades. For shops that need consistent results day after day, this machine becomes indispensable. The flexibility it offers means fewer setup changes during production runs, which translates to better quality control across batches and ultimately saves money on waste and rework costs over time.

Looking at something more specialized, the Wire Flattening Machine gets the job done when it comes to producing those exact wire widths needed for making staples and other similar products. Built tough with a strong alloy rim and equipped with water cooling system that helps maintain accuracy during operation, this equipment delivers consistent results time after time. The stability and uniform output make all the difference for companies that need their wires within tight tolerances. Many manufacturing operations simply cannot function without access to such precise flattening capabilities these days.

The Fully Automatic Industrial Galvanized Iron Wire Flattening Machine provides an advanced way to handle galvanized iron wire processing needs. Built according to strict industry requirements, this equipment allows accurate control over wire diameters while featuring special components such as alloy cone wheels that last longer under heavy use. Manufacturing facilities across various industries rely on machines like this when they need consistent results day after day. From construction materials production to automotive parts manufacturing, having reliable flattening capabilities makes all the difference in maintaining quality standards without sacrificing productivity.

Advantages of Advanced Wire Processing Techniques

Advanced wire processing techniques offer manufacturers a real money-saving benefit that cant be ignored. When companies adopt these new approaches, they typically see lower production costs because materials get used better and there's less reliance on expensive labor forces. Some factories report cutting down on wasted material by around 20% after implementing these changes, something that adds up to serious savings month after month. Take the example of automated wire forming systems powered by CNC machines. These setups make the whole operation run smoother while reducing the number of workers needed at each stage. Plus, production speeds pick up considerably compared to traditional methods.

Advanced wire processing tech gives manufacturers real customization options and flexibility when it comes to meeting what clients actually need. With these modern methods, companies can produce all sorts of specialized wire shapes and dimensions, making their products work better for different applications. A recent industry report found that around 70 percent of buyers really care about getting exactly what they want in wire products, showing just how crucial these capabilities have become. When businesses focus on what customers want, they see happier clients for sure, but there's another benefit too. Companies that can customize end up finding new market opportunities that others miss out on, especially since many competitors still struggle to match this level of personalization in their offerings.

Future Trends in Wire Processing and Metal Forming

Wire processing and metal forming industries are undergoing major changes thanks to new tech developments. Factories are adopting cutting edge tools like artificial intelligence and machine learning systems that boost accuracy across operations while keeping equipment running longer between repairs. Some plants report around 15 percent less downtime since implementing these smart solutions. The way these systems work is pretty straightforward actually – they analyze historical performance data to spot trends and optimize workflows over time. This means fewer mistakes during production runs and better quality control throughout the manufacturing process. What makes AI really valuable though is its ability to flag problems early on before minor glitches turn into expensive shutdowns, something every plant manager wants to avoid when trying to meet production targets.

The wire processing world is changing fast thanks to Industry 4.0 and automation bringing in smarter ways of making things. Manufacturers now rely on IoT gadgets and live data analysis to keep tabs on what's happening across their facilities, something that has boosted efficiency around 30% in many cases. These intelligent systems connect various parts of the manufacturing process smoothly, making everything run better together. When companies collect and look at data while it happens, they can make decisions quicker and tweak how they produce goods. This leads to saving money on resources and being able to respond faster when conditions change. As more factories adopt these new tech tools, the wire processing sector moves toward becoming a networked operation where information flows freely between machines and people, meeting the growing need worldwide for smarter factory setups.

EN

EN

AR

AR

BG

BG

CS

CS

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

LT

LT

SR

SR

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

AZ

AZ

KA

KA

BN

BN

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

KK

KK

UZ

UZ