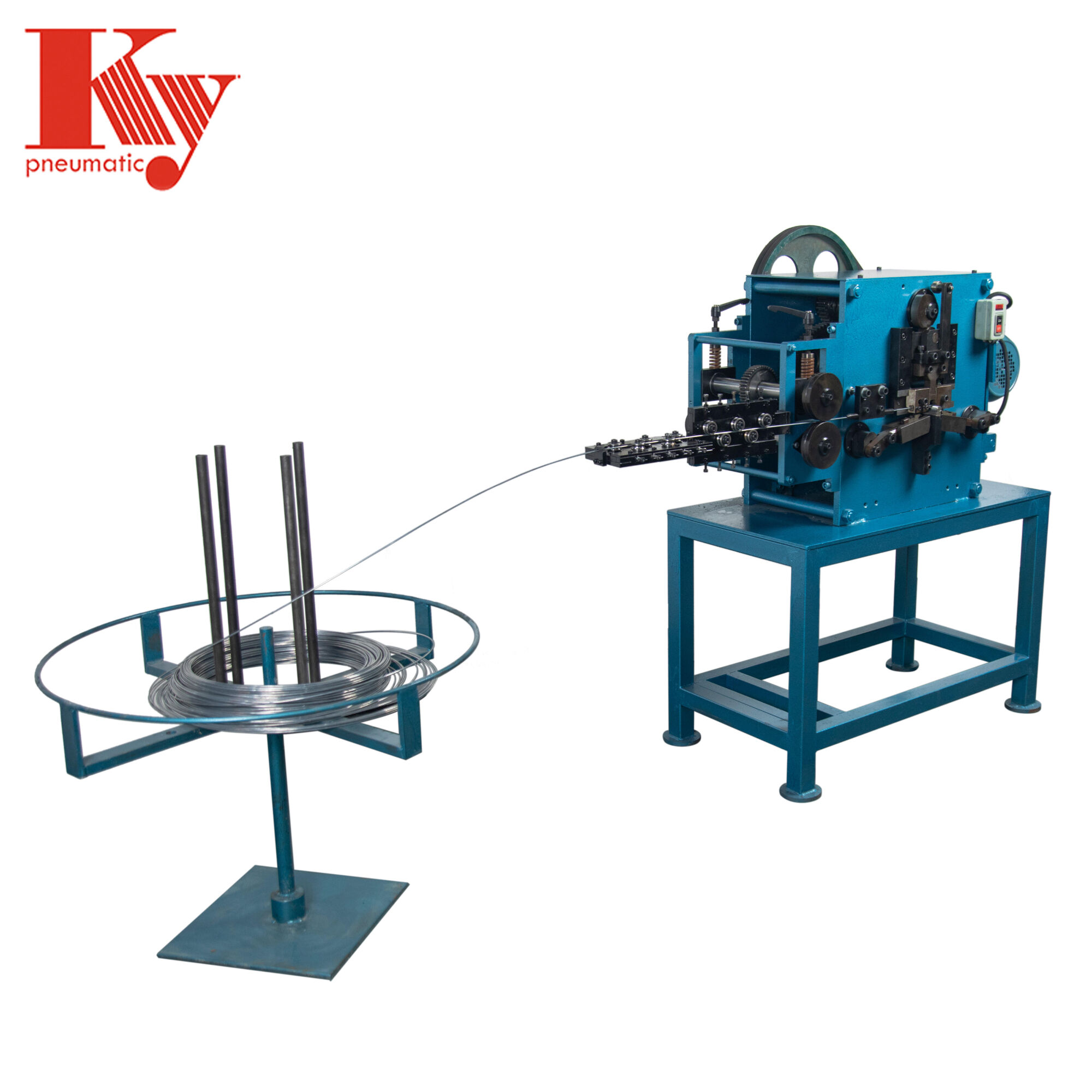

Hog Ring machine: manufacturing of special shaped staples

Understanding Hog Ring Machines

Hog ring machines are basically tools for attaching things together using those thick metal rings called hog rings. These aren't your standard office staplers working with flimsy wire staples. Instead, they tackle much heavier duty jobs because they work with thicker rings shaped either triangle or circle, usually made out of strong steel. The way these machines are built lets them hold together stuff that needs serious fastening like heavy fabrics, farm fences, or car seat covers. That's why mechanics, furniture makers, and farmers all rely on these machines when dealing with materials that just won't stay put with regular staples.

Hog ring machines work through some pretty sophisticated mechanics to form and hold those distinctive ring staples. These machines line up the hog rings then squeeze them around whatever needs joining together. Most models rely on compressed air systems which makes the whole operation faster and more accurate than manual methods. When properly compressed, the hog rings grip really tight. Some advanced units even include spot welding features for extra strength in critical applications. What makes these machines stand out compared to regular staple guns is their ability to handle heavy duty tasks without coming loose under pressure. Construction crews and industrial manufacturers depend on this reliability when working with materials that need permanent fastening solutions.

Key Benefits of Using Hog Ring Machines for Manufacturing Special Shaped Staples

Hog ring machines really boost how fast we can make those special shaped staples in factories. Take a look at the numbers some manufacturers report output rates that beat what workers could ever achieve manually. The automation aspect is a game changer too. Factories using these systems often need just one or two people watching over operations instead of entire teams. That cuts down on payroll expenses while keeping production moving at lightning speed. When orders come rolling in with impossible deadlines, having hog ring technology means getting products out the door on time without breaking a sweat. Many plant managers will tell you these machines have become essential during peak seasons when demand spikes unexpectedly.

Hog ring machines aren't just about getting things done quickly either. They work wonders in all sorts of places too. Take pet product manufacturers for starters. These companies rely on them to put together those plastic cages and travel carriers we all know so well. Furniture makers love them too because nobody wants their couch coming apart at the seams. Hog rings keep upholstery secure while giving that finished look customers expect. And don't even get me started on packaging operations where these little metal rings seal everything from grocery bags to industrial containers. Some setups actually pair them with special wire drawing equipment for extra strength. The point is, no matter what business someone runs, there's probably a way to make better use of hog ring technology without breaking the bank on specialized machinery.

Different Types of Hog Ring Machines

There are several kinds of hog ring machines out there, but manual and pneumatic models tend to dominate the market. Manual versions need actual muscle power from operators, so they work best for small jobs or when no power source is around. Pneumatic machines operate using compressed air instead, which gives them a real edge when it comes to how fast they can run and how consistently they perform. These automatic systems boost output dramatically while cutting down on tired workers, especially important in factories cranking out thousands of products daily. Some shops find the initial investment worth it just for the long term savings on labor costs alone.

In addition to the standard manual and pneumatic options, some manufacturers turn to specialty hog ring machines when they have unique production demands. What makes these machines stand out is their adjustable settings which let operators work with different staple shapes and sizes including those tricky C-rings, D-rings, and even the less common M-shaped ones. For companies dealing with all sorts of fastening challenges across multiple products, this kind of customization really matters. It gives them both flexibility and accuracy on the factory floor. When businesses pick the correct machine for their particular needs, they not only streamline their fastening operations but also ensure compliance with whatever standards their industry requires.

Products Overview

The Hog Ring Machine stands out as quite versatile when it comes to turning round wire into finished goods while keeping things quiet and stable during operation. Industries that demand exact measurements find this machine especially useful. Think about places making pet cages where consistency matters, or auto part factories needing those tiny rings just right, even furniture makers who rely on uniformity across their products. What makes this equipment so valuable in workshops? Well, one person can actually handle multiple machines at once, which really boosts productivity without adding extra staff. Plus, there are built-in features like automatic counters, cutting mechanisms, and straightening components all working together behind the scenes to deliver consistently accurate output every time.

The C Ring Staple Hog Ring Making Machine takes care of everything from raw wire all the way through to finished staple rings, delivering solid performance while keeping noise levels down on the factory floor. Manufacturers across different sectors have adopted this equipment for making animal cages, furniture parts, and various automotive components. What makes it stand out? Precise temperature controls combined with automated functions boost both productivity and accuracy when producing these metal fasteners. Many shops report significant improvements in their workflow after integrating this type of machinery into their production lines.

Applications of Hog Ring Machines in Various Industries

Hog ring machines find their way into all sorts of industrial settings, becoming pretty much indispensable tools across manufacturing shops and workshops. When it comes to making pet cages specifically, these little devices play a big role in keeping those cages safe and sturdy over time. The hog rings themselves act like heavy duty clips that hold metal wires and mesh panels firmly in place throughout the assembly process. Without proper fastening, there would be gaps between sections where curious paws might get stuck or escape through. Pet owners want peace of mind knowing their furry friends won't accidentally break free from what should be a secure enclosure. That's why many cage makers rely heavily on hog ring technology during production runs.

Hog ring machines have become essential tools in modern furniture production for putting together frames and fastening upholstery materials. When manufacturers need to secure fabric onto wood or metal bases, regular staples just don't cut it most of the time. What makes hog rings so effective is their pointed tips combined with robust build quality that lets them pierce through even dense padding without much trouble. The result? Upholstery stays firmly in place for years instead of coming loose after just a few months of use. For furniture makers looking to balance durability with appearance, these specialized fasteners make all the difference in keeping products looking good while standing up to daily wear and tear.

Choosing the Right Hog Ring Machine

Finding the right hog ring machine makes all the difference in getting the most out of a production setup. There are several things worth thinking about before making a purchase decision including how much stuff needs to be processed, what kinds of staples will be used, and obviously money matters too. For facilities running at full tilt day after day, having access to machines capable of handling different staple sizes and shapes really pays off in terms of flexibility and getting work done faster. Money does play a role in equipment selection obviously. While top shelf models come with bigger price tags, going too cheap can end up costing more down the road when performance starts to lag behind expectations. The sweet spot usually lies somewhere between what fits the wallet and what actually gets the job done without constant headaches.

When looking at what they need for production, companies would do well to follow a good evaluation process. Start with taking a close look at what's being made now and what might be needed down the road. Think about things like what kind of materials are involved and how often equipment gets used day to day. Write all this stuff down somewhere and then check it against what different hog ring machines can actually handle. Pay attention to special features that match specific needs and don't forget to read through those spec sheets carefully. Making smart choices based on these factors leads to better results overall. Following this sort of thoughtful planning helps make sure whatever machine gets bought will work just right for whatever the shop throws at it.

Future Trends in Hog Ring Machine Technology

Things are changing fast in the world of hog ring manufacturing these days. We're seeing some pretty cool advances happening, especially when it comes to new materials being developed and better simulation tech getting adopted across the industry. What does this mean for actual products? Well, basically hog rings are becoming tougher and more functional than ever before. They can now handle much harsher conditions without breaking down. Take a look at what's happening with those high strength alloys and special coatings that manufacturers are starting to use. These additions really boost how well they stand up to wear and tear over time. And let's face it, longer lasting hog rings save money in the end because they don't need replacing so often.

Hog ring manufacturing has seen major gains in productivity thanks to automation technology. According to industry reports from last year, around two thirds of companies making these fasteners have brought automation into their factories, which typically boosts output by about twenty percent. Looking ahead, we're seeing more robotic systems and smart machines being integrated into production lines. These advancements help cut down on mistakes made by workers, save money on day to day expenses, and generally make the whole manufacturing process run smoother. The way hog rings get produced today looks very different from just five years ago, with applications expanding into new areas as manufacturers continue to refine their automated approaches.

EN

EN

AR

AR

BG

BG

CS

CS

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

LT

LT

SR

SR

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

AZ

AZ

KA

KA

BN

BN

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

KK

KK

UZ

UZ