The Inner Workings of Staple Machines

Core Mechanics of Staple Machines

The Wire-to-Staple Transformation Process

Turning wire into staples is no simple task, and manufacturers go through quite a bit to make sure each one hits those quality marks. Most of these little fasteners start life as high tensile steel wire because it just holds up better over time, especially when they're used in heavy duty applications around factories or construction sites. The whole process goes something like this first they cut the wire down to exact sizes, then bend those pieces into the familiar U shape we all know, followed by various treatments that toughen things up, including some heat work that makes them stronger. Industry folks have noticed that streamlining these steps cuts down on material waste while cranking out more finished products per hour. When it comes to quality checks, companies run rigorous tests throughout production to catch any duds before they leave the factory floor. And lately there's been some pretty cool tech coming online automated systems that handle the wire bending with laser precision, plus improved drying methods that speed up processing times without compromising on quality standards.

Role of Feeding Mechanisms and Precision Molds

The feeding system in staple machines keeps wire moving steadily through the equipment, something that's really important for keeping production going nonstop. Without proper feeding, materials stop coming in regularly, causing all sorts of problems on the factory floor and slowing down how much gets made each day. When it comes to making staples themselves, precision molds do most of the work. They shape each staple so they all look basically the same. Why does this matter? Well, staples need to fit properly in whatever application they're used for, whether it's binding documents or attaching tags to products. Different models of staple machines actually have various feeding systems installed, and these differences affect how well the whole machine runs. Good quality molds make a big difference too. Industry studies show time and again that when staples maintain consistent sizes and shapes throughout batches, machines run smoother and require fewer adjustments during operation.

Automated vs Semi-Automated Operation Systems

Staple machines that are fully automated stand apart from semi-automated versions mainly when it comes to how efficiently they work and what they cost upfront. The automated ones generally crank out more product per hour but come with bigger price tags at the start. Still, most companies find they pay off faster because they just keep going nonstop. Industry reports show factories that go all in on automation tend to produce way more stuff than places stuck with half measures. That said, there's still room for semi-automated setups too. Small shops or startups often stick with them since they don't have the budget for complete automation packages. These machines usually have straightforward controls and basic parts that regular workers can handle without special classes. For many small businesses, this kind of equipment represents a smart middle ground where they can grow production without breaking the bank on expensive machinery.

Specialized Staple Machine Variants

Packaging Staple Machines for Carton Sealing

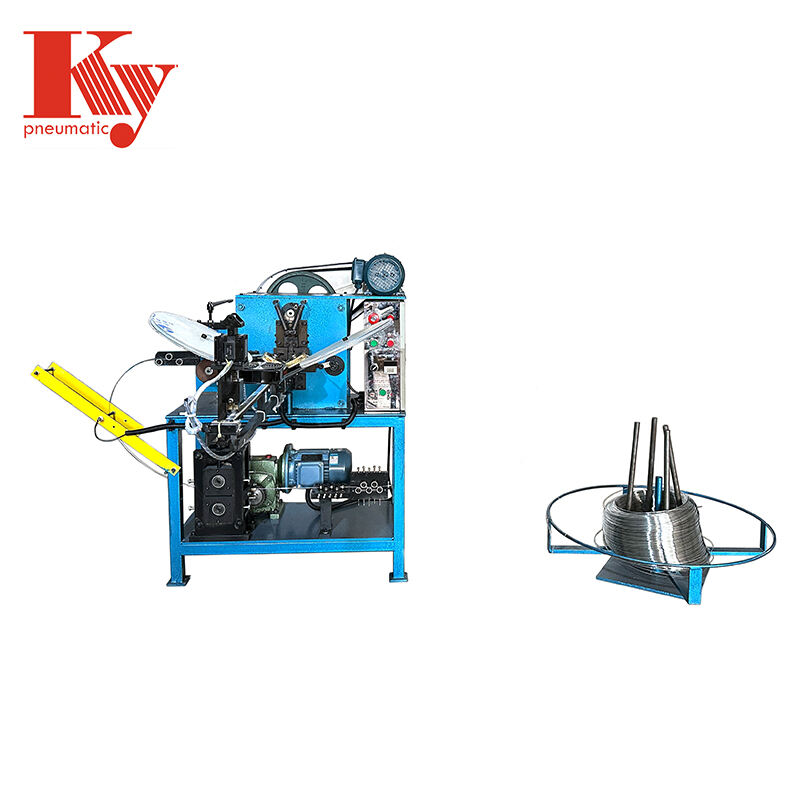

Staple machines for packaging come equipped with features specifically built to make carton sealing work better. What makes these machines stand out is how they handle sealing tasks efficiently through special design elements that match what packaging operations need. Companies that switch to these dedicated machines see real benefits on the factory floor. Production speeds pick up while workers spend less time on manual sealing jobs, cutting down overall labor expenses by around 30% according to recent industry reports. The market for these machines keeps expanding as manufacturers realize their value. Take Dongguan Shilong Ky Nailing Equipment Factory for instance, one of the big names in this space. They've developed several machine models over the years that address particular packaging challenges faced by different industries.

High-Carbon Steel Models for Industrial Fastening

High carbon steel staples really hold up well over time, making them perfect for tough jobs in places like construction sites or heavy manufacturing plants. What makes these staples special? They have amazing strength that doesn't break down easily, something labs have confirmed through countless tests. We're seeing more manufacturers switch to these steel staples lately because they just plain work better. The construction industry has been one of the biggest adopters, followed closely by automotive repair shops and even some food processing facilities. Companies report all sorts of benefits after making the change including fewer breakdowns during operation and spending less money fixing equipment down the road. Some businesses say maintenance costs drop by almost half once they start using high carbon steel instead of cheaper alternatives.

D-Ring Machines for Animal Cage Construction

The D-Ring staple machine has become a go-to solution for building animal cages thanks to some pretty special features that just work better for this particular job. What sets these apart is how well they handle different materials while still keeping everything securely fastened even after repeated use. The poultry farming sector especially relies heavily on them since they pass all those strict safety checks required by modern regulations. People who actually work with these machines day in and day out tend to rave about how dependable they are compared to other options out there, which explains why so many small businesses stick with D-Ring models despite the initial investment cost.

Industrial-Grade Staple Machines for Specialized Applications

HR22 D-Ring Staple Machine: Features & Benefits

The HR22 D-Ring Staple Machine really shines among industrial staple machines because of how tough it is and all the different ways it can be used. What sets it apart is that it handles everything from raw wire right through to finished staples without needing much intervention. The whole process runs smoothly and quickly, which saves time on the factory floor. Workers love this machine for two main reasons actually - first, it stays stable even during heavy use, and second, it doesn't make much noise at all. That's why so many pet cage makers, furniture factories, and automotive parts shops have started using them. One big plus is how productive they are. A single operator can keep track of up to five HR22 units at once without breaking a sweat. Plus there are handy built-in features like an automatic counter that tracks production numbers and self-adjusting parts that reduce downtime. These little touches make the machine easy to operate and maintain, which means less frustration for everyone involved.

Fully Automatic 4K High-Carbon Steel Staple System

The Fully Automatic 4K High Carbon Steel Staple System represents a major leap forward in staple manufacturing technology for industrial applications. This machine delivers exceptional speed while producing consistent output, making it ideal for creating those high quality steel staples needed across various sectors. Furniture makers working with aluminum frames or wrought iron components find this equipment particularly valuable since it cuts down on manual labor requirements and keeps production running smoothly day after day. What sets this apart is how precisely it controls dimensions – we're talking about tolerances within just 0.1mm between each staple produced. That kind of accuracy means fewer rejects and wasted materials when producing large quantities. Factory managers who've installed these systems report not only better product quality but also noticeable gains in overall shop floor productivity according to their maintenance logs and employee feedback surveys.

Critical Components Ensuring Performance

Precision Straightening Devices Explained

Getting those staples just right requires good precision straightening equipment. When the wire gets properly aligned before cutting and shaping happens, it makes all the difference in how well the final product works. There are basically two main kinds out there these days: roller systems and lever mechanisms. Each has its own strengths as manufacturers design them for specific applications. Studies show that when staples are correctly aligned thanks to these precision tools, feeding problems drop off dramatically and machines run more efficiently overall. The newer models with adjustable rollers have really taken things to another level though. They make the whole process much smoother, especially important when dealing with high volume production lines where even small improvements matter big time.

Temperature-Controlled Molding Technology

Controlling temperatures during the molding process makes all the difference when producing staples, since heat really affects how they turn out. If we don't get the temperature just right, staples might end up too brittle or not form properly at all. Industry research keeps pointing to one thing over and over again: when manufacturers maintain proper temperatures throughout production, their staples last longer and look more consistent across batches. Some companies have started using special equipment like thermoregulated molds or those induction heating coils to manage temperatures better, which actually translates into improved results on the factory floor. Real world examples from manufacturing plants show that after implementing these temperature control systems, there's often a noticeable jump in both product quality and how fast things can be made.

Error-Rated Feed Systems (±0.1mm Accuracy)

Getting error rates down in feed systems makes all the difference for accurate staple production. These systems can hit precision levels around ±0.1mm, which is pretty much industry standard for quality work. Looking at actual shop floor data shows that machines hitting this level produce way fewer rejects than ones that aren't as precise. What keeps these systems running so accurately? A combination of optical sensors and those servo motors doing the heavy lifting behind the scenes, making sure wires land exactly where they need to go during production runs. From a business standpoint, better accuracy means real money saved over time, products that meet spec consistently, and happier customers who get what they paid for. That kind of reliability gives manufacturers a solid edge against competitors still struggling with inconsistent output.

Maintenance & Efficiency Optimization

Routine Cleaning Procedures for Longevity

Routine cleaning is crucial for extending the lifespan of staple machines and maintaining their optimal performance. Regular cleaning helps prevent excessive wear and tear on critical components, such as the precision straightening devices and feed systems. To ensure efficient operation, follow these steps:

- Power Off: Begin by safely powering off the machine to avoid accidents during cleaning.

- External Wipe Down: Use a lint-free cloth to remove dust and debris from the exterior surfaces.

- Straightening Device Check: Carefully inspect and clean the precision straightening devices to ensure they are free from obstructions.

- Feed System Maintenance: Clean all moving parts of the feed system to prevent jamming.

- Internal Inspection: Open the machine's casing to clean internal parts with a compressed air blower.

- Lubrication: Apply lubricant to essential components post-cleaning to maintain smooth function.

Experts emphasize the advantage of regular maintenance. Findings show that consistent cleaning practices significantly increase the longevity and reliability of staple machines.

Troubleshooting Common Jamming Issues

Understanding the common causes of staple machine jamming can help operators reduce downtime and optimize performance. Frequently, issues arise due to poor material quality or mechanical failures associated with feed systems. Here are effective troubleshooting steps:

- Material Inspection: Ensure materials are consistent and meet quality standards. Low-quality staples may cause jams.

- Proper Alignment: Check staple alignment within the feeder to prevent misfires.

- Clearing Blockages: If jamming occurs, promptly clear any blockages in the feed path.

- Component Check: Regularly inspect moving parts for wear or damage that could lead to jams.

- Calibration Tests: Run calibration tests to ensure mechanism precision.

Implementing these preventive measures can avoid costly downtime. Manufacturers underscore the importance of routine checks to anticipate and avoid potential jamming issues.

Upgrading Mold Sets for Different Staple Profiles

Mold sets play an essential role in producing various staple profiles tailored to specific applications. Upgrading these molds can significantly enhance production adaptability and efficiency. When selecting new molds, consider the following:

- Material Compatibility: Choose molds that align with the staple materials to ensure quality production.

- Volume Requirements: Evaluate production capacity to select molds that meet demand scalability needs.

Upgrading molds involves careful planning and execution. By adopting mold upgrades, industries can efficiently respond to evolving demands, enhancing both the efficiency and quality of staple production. Many industries heavily benefit from such upgrades, adapting to varying market conditions seamlessly.

EN

EN

AR

AR

BG

BG

CS

CS

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

LT

LT

SR

SR

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

AZ

AZ

KA

KA

BN

BN

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

KK

KK

UZ

UZ