Brad Nail Making Machine: A Guide

How Brad Nail Making Machines Transform Wire into Fasteners

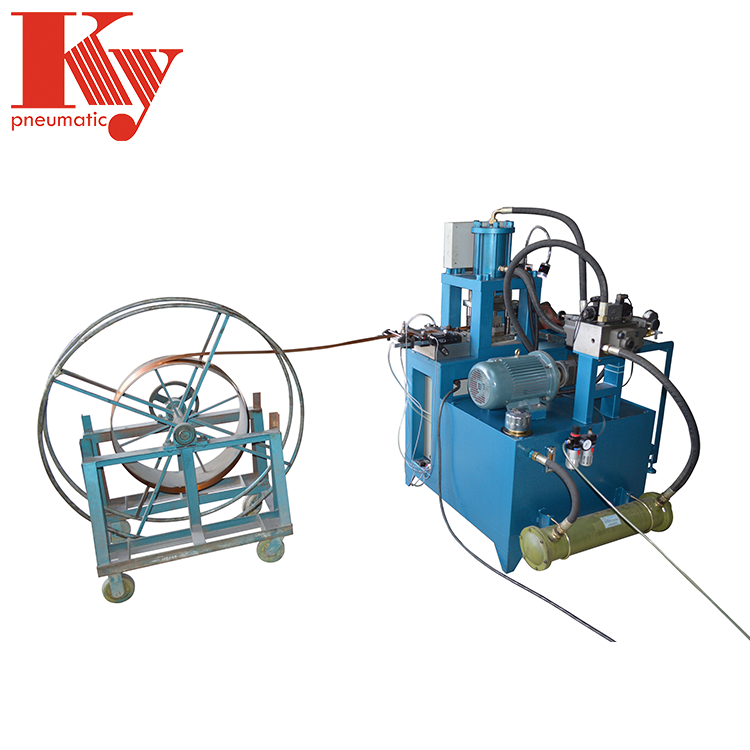

Wire Feeding and Straightening Process

Making brad nails starts when raw wire gets pulled through the feeding system. A bunch of rollers take care of guiding the wire off its spool so there's no interruption while manufacturing runs. Getting this part right matters a lot for keeping up production speeds, especially important in factories where output needs to stay consistently high. After feeding, the wire goes through straightening with mechanical guides and air-powered systems working side by side to knock out any bends or twists. The straightening stage really counts because if there are even tiny flaws in the wire, those will show up in the finished nails and impact their performance. Modern equipment takes things further with built-in sensors that keep track of where the wire is at all times. These let operators tweak settings on the fly, which helps maintain quality standards while running at top speed.

Precision Cutting and Head Forming

Getting the measurements right matters a lot when making nails, especially during cutting and head forming stages. Modern cutting systems come with razor sharp blades that slice through wire stock precisely so each piece ends up exactly the right size for whatever nail is being made. When done properly, this attention to detail means fewer rejects because nobody wants nails that're too short or long for their intended purpose. After cutting comes shaping those little caps on top. Manufacturers use special dies to press out heads in all sorts of shapes flat ones work best for certain construction jobs while rounded heads might be preferred elsewhere in the market. Many newer machines actually let operators switch out tooling pretty fast if they need to adjust design specs between batches. The real game changer though has been incorporating computer numerical control tech into these operations. With CNC systems handling both cutting and forming tasks, there's much less room for error and far less wasted material going down the drain. For companies running production lines day after day, this kind of precision translates directly into savings at the end of the month.

Automated Quality Control Systems

Quality control systems have become essential in modern nail manufacturing, stopping substandard products from reaching customers. Most facilities now use advanced vision tech that scans each nail as it comes off the production line, catching flaws instantly before they get packaged. These checks help meet all sorts of regulations while keeping up with customer expectations for consistent quality across batches. Manufacturers run various tests on samples too, like stress tests to see if nails hold up under pressure and tensile tests to measure how much force they can withstand before breaking. Looking at data from these inspections helps spot patterns over time, so companies know when to tweak their processes. By catching problems early instead of dealing with them later, factories save money on wasted materials and keep their operations running smoothly without constant interruptions for fixes.

Key Advantages of Automated Nail Production

High-Speed Output: 100-160 Nails/Minute

The introduction of automated nail making machines represents a major boost in how fast these products can be manufactured, reaching impressive rates between 100 and 160 nails every single minute. With such incredible speed, factories are able to keep up with what consumers want right now without breaking a sweat. When we look at traditional hand made approaches versus automation, there's no contest really. Machines produce around three times as many nails compared to what humans could manage manually, which makes all the difference when it comes to running a successful business. Plus this kind of productivity means companies aren't stuck waiting forever to expand their capacity whenever new opportunities arise in the marketplace.

PLC Control for Customizable Operations

Adding PLC systems to automated nail production equipment really boosts how flexible manufacturers can be on the factory floor. When operators need to switch between making small finishing nails and larger construction grade ones, they just tweak a few settings instead of tearing apart entire machines like old school methods required. The result? Less waste from rejected products and better overall efficiency as these machines keep running smoothly day after day. Nail producers find themselves able to meet sudden changes in what customers want much faster than before, which makes all the difference when competing against other suppliers in tight markets.

Reduced Material Waste and Labor Costs

Bringing automation into nail manufacturing does more than just speed things up it actually cuts down on wasted materials and saves money on labor too. The machines cut nails with much greater accuracy than humans can manage, which means less scrap ends up in landfills. According to industry reports, companies have seen their labor expenses drop around 30% since implementing automated systems because there's simply no need for someone to watch every step of the process anymore. What this really means for manufacturers is they now have extra funds to invest back into their operations. Some are spending on better quality control measures while others are developing new products that give them an advantage over competitors still relying on traditional methods.

Critical Features in Modern Nail Making Machinery

Durable Mold Designs for Longevity

When building molds for nail making machines, durability matters a lot because these molds typically need to withstand constant wear and tear. Most manufacturers go for high tensile strength materials when crafting their molds so they last longer and keep performing well even during those marathon production runs. Testing molds regularly every few months helps catch potential problems before they become major headaches. Some companies upgrade their mold designs once or twice a year based on what works best in practice. For businesses serious about maintaining consistent output without unexpected breakdowns, spending money on good quality molds that meet industry standards pays off handsomely over time. Better molds mean fewer interruptions and higher overall productivity across the board.

Automatic Lubrication Systems

Modern nail making equipment comes with built in auto lubrication systems that keep all those moving parts properly greased up, cutting down on friction and wear over time. The result? Machines last longer and run more reliably. Some newer models actually let operators check oil levels from afar through their smartphones or computers, so they can manage maintenance without constantly checking the machine itself. When everything stays well lubricated, the whole operation runs smoother and uses less power too. For factory owners watching their bottom line, this means real savings on both repair bills and energy costs. Makes sense why so many shops are upgrading to these smarter systems these days.

Safety Mechanisms: Overload Protection

Modern nail making machines simply wouldn't work without proper safety measures built right in. Most of these machines have overload protection systems that shut down automatically when something goes wrong mechanically, which helps keep operators from getting hurt. Alongside this basic protection, there are also standard safety procedures such as emergency stops and warning lights throughout the factory floor. These help make sure everything follows local safety laws and regulations. Companies need to do regular inspections and maintenance on their equipment too. This isn't just about following rules though it actually makes good business sense since damaged machinery costs money to fix and injured workers mean lost productivity. Many manufacturers find that keeping up with safety standards ultimately saves them time and money in the long run while maintaining reliable operations across different production environments.

Top Brad Nail Making Machine Models

T Brad Nail Making Machine: Precision for T-Series Nails

Designed specifically for T-series nails, the T Brad Nail Making Machine delivers exceptional accuracy right from the factory floor. The adjustable measurements are spot on most of the time, so every nail coming off the line typically hits those tough industry specs without much hassle. Factory workers who've used this machine often mention how fast it runs through batches while still keeping quality consistent, which matters a lot when producing thousands of nails daily. While there are plenty of options out there, many manufacturers consider this particular model among the top performers because it combines solid build quality with tech features that actually work in real world conditions rather than just sounding impressive on paper.

F Brad Nail Making Machine: Versatile F-Series Production

The F Brad Nail Making Machine stands out because it can handle all sorts of F-series nails across various wire sizes without much trouble at all. Most manufacturers go with this particular model since it runs reliably day after day and doesn't require complicated setup procedures, something that really boosts their ability to switch between different production requirements quickly. The company behind it keeps improving things through ongoing R&D efforts, adding practical upgrades that actually address real problems faced by workshops looking to get more done while using fewer resources over time.

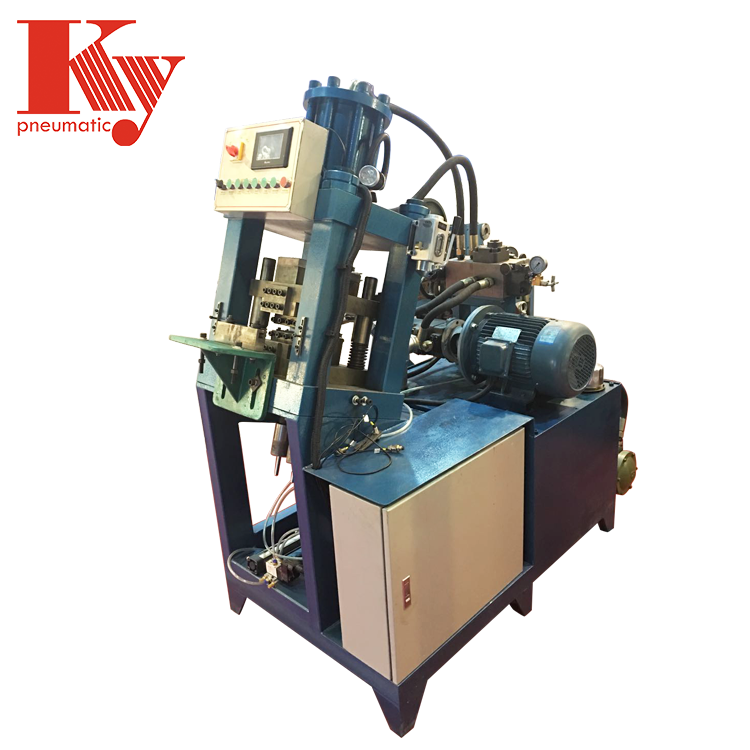

Auto Pneumatic Model: Dual-Operation Efficiency

What sets the Auto Pneumatic Model apart is its ability to handle two different operations at once, making it possible to switch between various nail types right in the middle of production without stopping everything. The pneumatic system inside works much quicker than older models, which means factories can produce nails faster while using less energy overall. Factory managers who've tested this machine report seeing real improvements on their shop floors. One plant manager mentioned cutting down changeover time by almost half during a recent shift. As manufacturing tech continues evolving, machines like these represent significant progress for the nail industry. They help streamline workflows and reduce waste across the entire production process.

T/F Series Machine: Multi-Gauge Compatibility

Manufacturers love the T/F Series Machine because it works with multiple gauges, making it really versatile for different production needs. The machine adapts well to what customers want on the factory floor. Market research shows that companies from all sorts of sectors are gravitating toward this equipment. Many shops report better efficiency after switching to the T/F model. As fastener makers need to handle more varied specifications these days, investing in a machine that can switch between gauges without major retooling just makes sense financially. Some plants have seen their output increase by 30% since incorporating this technology into their workflow.

Maintenance and Operational Best Practices

Routine Mold Inspection Protocols

Checking molds regularly helps stop unexpected problems from messing up nail production. When manufacturers spot signs of wear before they become major issues, they save money on expensive repairs and avoid costly downtime while keeping their production running smoothly. Most shops find that setting up regular checks makes sense based on how much they produce each month. Some companies check weekly during peak seasons but maybe monthly otherwise. Industry experts suggest keeping records of all these inspections too. Writing down what was found during each check creates a paper trail that helps track patterns over time. This kind of organized system means small problems get fixed fast before they turn into bigger headaches, so the whole operation keeps moving without interruption.

Optimizing Wire Feeding Consistency

Keeping wire feeding consistent matters a lot when it comes to getting good production numbers and quality products out there, something most folks talk about on those industry message boards. When looking at things like wire specs and how machines are performing, manufacturers need to tweak their feeding systems accordingly. Getting the wire feeding just right can really make a difference both in how fast things get made and how accurate the results turn out. All these little improvements stack up over time, which means factories run smoother and waste less material. For anyone working with nails specifically, paying close attention to these details makes all the difference between a decent operation and one that stands out from competitors.

Utilizing OEM Technical Support

Working with OEM technical support really helps improve manufacturing operations across the board. When companies get access to up to date maintenance info and industry best practices from these manufacturers, their machines tend to run better overall. Most OEMs offer special training sessions too, which teaches operators how to handle equipment properly and safely. According to some industry stats, factories that make good use of OEM resources see far fewer breakdowns and stoppages during production runs. The bottom line is straightforward: when manufacturers tap into OEM support networks, they end up getting more machine uptime, which translates directly into a stronger position against competitors in the market place.

EN

EN

AR

AR

BG

BG

CS

CS

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

LT

LT

SR

SR

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

AZ

AZ

KA

KA

BN

BN

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

KK

KK

UZ

UZ