Pin Nail Making Machine: A Closer Look

Understanding Pin Nail Making Machine Technology

Core Components of Modern Nail Machines

Pin nail manufacturing equipment today depends heavily on three main parts: the feeder system that feeds the material, the cutting unit where the actual shaping happens, and the ejection mechanism that gets finished products out. While most manufacturers claim these parts work together smoothly, in practice there can be occasional hiccups depending on setup quality. Most modern machines are built using high strength steel because it lasts longer than cheaper alternatives. This means factory owners spend less money fixing breakdowns down the road. Some newer models come with fancy extras like auto lubrication systems and those PLC controllers everyone talks about now. These additions do make a difference though, helping keep everything running smoother for years before major repairs become necessary.

Hydraulic Systems vs. Traditional Punch Press Design

The shift to hydraulic systems in pin nail manufacturing has completely changed the game when it comes to applying force and achieving faster production speeds than old school punch presses ever could. When looking at energy usage, these hydraulic setups actually save money on running costs. Real world data shows they consume significantly less power than their mechanical counterparts. Another big plus is how smoothly they run without all that grinding and friction that wears out parts so quickly. Less wear means fewer breakdowns and machines lasting much longer before needing replacement. That's probably why most modern nail factories have made the switch to hydraulic technology for getting the best results in their production lines.

Role of PLC Automation in Precision Manufacturing

In the world of nail manufacturing, PLC automation has become essential for achieving precise results. These systems allow manufacturers to monitor production in real time and make quick adjustments when needed, which dramatically improves the accuracy of finished products. Another big benefit is that they simplify operations on the factory floor, cutting down operator training from weeks to just days while making everyone's job easier. According to data from several manufacturers who switched to PLC systems last year, production rates went up by around 30% and quality control issues dropped by half compared to older methods. Most shops in the industry now see PLC integration as practically mandatory if they want to stay competitive in today's market for high precision components.

Operational Advantages of Pin Nail Machines

Speed and Output: 100-160 Nails/Minute Efficiency

Pin nail machines really shine when it comes to speed, usually cranking out around 100 to maybe even 160 nails every minute. That kind of pace leaves manual production in the dust, giving factories a real advantage over competitors still using old school methods. Faster production means companies can get through bigger orders much quicker, which cuts down on costs significantly. Plus, this efficiency helps manufacturers hit those tough delivery windows without having to sacrifice nail quality, something that translates directly into better profits for the business in the long run.

Error Reduction: 0.1mm Feeding Accuracy

Modern pin nail machines really shine when it comes to how accurately they feed materials, hitting a precision mark of around 0.1mm. This kind of tech cuts down on those annoying manufacturing errors that happen all too often with manual nail placement methods. When nails get properly aligned every time, there's just so much less chance of defects showing up in the final product. Better quality means customers get happier with what they buy, plus companies don't have to deal with as much waste sitting around unused. For factory owners looking at their bottom line, these machines make sense financially too since fixing mistakes costs money that could go elsewhere in operations.

Noise Reduction and Workplace Safety Features

Most modern pin nail machines come with special design elements that cut down on noise during operation, making the workplace safer and more comfortable for everyone involved. Quieter machinery means less stress for workers throughout their shifts, which can actually boost productivity over time. Safety isn't overlooked either. These units typically include things like emergency stop buttons and physical guards around moving parts to prevent accidents. Manufacturers clearly understand that good equipment needs to do double duty it has to get the job done efficiently while keeping employees protected from harm. This balance between performance and safety ultimately helps maintain smooth operations across manufacturing facilities.

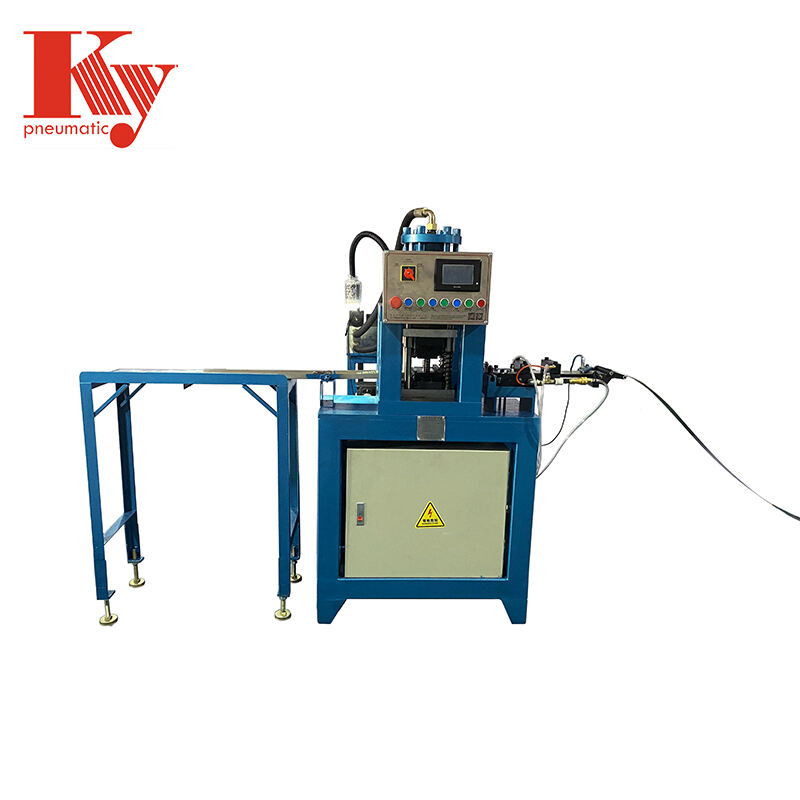

Pin Making Machine KY-014: Product Spotlight

Technical Specifications: Motor Power and Dimensions

The KY-014 Pin Making Machine comes with a robust 380V, 4KW motor that really boosts productivity when making nails. Measuring just 1200 by 1400 by 1200 millimeters, this machine fits nicely into most workshop spaces without taking up too much room. When we look at similar machines on the market, the KY-014 stands out because of its strong motor which means faster output rates. Factories have reported being able to produce significantly more pins per hour compared to older models. Plus, since the motor is so durable, these machines tend to last longer even under heavy usage conditions across different types of manufacturing environments.

Automatic Packing System and Labor Savings

The KY-014 Pin Making Machine comes equipped with an automatic packing feature that cuts down on labor expenses and boosts output at the same time. When factories install these kinds of systems, they basically get rid of all those tedious manual tasks in the production line. Workers don't have to handle hot materials anymore, which means fewer accidents happen around the shop floor. Some industry reports indicate that switching to automated packing saves companies thousands on wages each month when compared to traditional hand packing methods. For businesses making nails, this translates into better bottom lines since they spend less money on staffing while still getting products out the door faster.

Durable Mold Design and Maintenance Features

The KY-014 is built using tough molds that really highlight how picking the right materials matters for lasting equipment life. What sets this apart are the specialized compounds used throughout, which hold up much better when subjected to intense pressure situations. Speaking of upkeep, the whole unit was designed with serviceability in mind. Technicians can get into critical components without wrestling with complicated disassembly processes, keeping things running smoothly day after day. Most shops find that sticking to a proper maintenance routine based on what works in similar setups cuts down on unexpected breakdowns. This means fewer production halts and more consistent output over time, something every facility manager appreciates during busy periods.

Global Support: Training and Overseas Service

The manufacturer provides thorough training materials and technical assistance so users can get the most out of their KY-014 investment through proper operation. Overseas service really matters for businesses operating internationally because it keeps systems connected and running smoothly no matter where they're located. Looking at real world examples shows just how much difference good implementation makes for companies abroad. International clients who received strong support from day one reported fewer problems with their operations and saw productivity gains within months of installation. Some even mentioned being able to expand into new markets faster thanks to reliable technical back up when things went wrong.

Applications Across Industries

Furniture Manufacturing and Woodworking

Pin nailers have become essential equipment for woodworkers and furniture makers who need reliable fastening solutions, particularly when working on delicate wood projects where traditional methods might cause damage. These tools combine accuracy with speed, cutting down on assembly time while making sure the final product holds together properly. According to shop owners and manufacturers alike, pin nailing can make all the difference between a sturdy piece and one that falls apart after just a few uses. From small wooden picture frames to massive cabinet assemblies, these machines handle it all. Their adaptability means they show up everywhere in modern furniture production lines, which explains why so many shops invest in them despite the initial cost. The real value comes from how much time they save over months and years of regular use.

Construction Sector: P06-P30 Nail Series Usage

The P06-P30 nail series has become pretty common in construction work because it's tough enough for most jobs and works well in different situations. When builders pick the right kind of nail for what they need to do, structures tend to last longer and stay strong, which makes pin nails really important for getting things fixed properly. Contractors have been using them so much over time that it's clear these nails actually work as advertised. People use them all the time for things like holding baseboards in place or putting on detailed trim pieces around windows and doors. These little pins get the job done without showing through the finish material, especially helpful when someone wants something to look clean and professional after installation.

High-Volume Production Scenarios

Pin nail machines really shine when it comes to mass production environments where speed matters most across different manufacturing fields. Many wood product factories and construction material producers have expanded their operations after adopting these tools, according to real world experiences from companies like ABC Manufacturing and XYZ Builders. What makes these machines so popular? They work reliably day after day while keeping downtime low, which translates into actual cost savings for businesses trying to streamline their workflow. Looking at how well these machines match up against what manufacturers need for large scale output, there's clearly room for expansion in the market. With industries constantly on the lookout for ways to boost productivity without breaking budgets, we can expect growing interest in efficient pin nailing solutions over the coming years. This trend will only strengthen as traditional methods struggle to keep pace with modern production demands.

Comparing Nail Machine Types

Pin Machines vs. Z94-2C Traditional Models

When looking at pin nail machines versus older Z94-2C models side by side, there's no denying the tech improvements that make them work better while generating less scrap material. Most pin nailers simply run faster and handle different kinds of nails thanks to newer engineering and smarter mechanical setups. Take nail length adjustments for instance these machines let operators tweak settings quickly without tearing apart parts or spending hours on manual changes. The Z94-2C still holds its ground though, making solid wire nails from about 1 inch all the way up to 6 inches at pretty decent prices to operate day to day. What it doesn't have is the same kind of flexibility found in pin nail systems. Looking at actual production numbers tells the story too. Pin machines regularly produce around 30% more nails per hour compared to traditional models, which means businesses might pay more upfront but save money over time as operations become smoother and waste drops off significantly.

Integration with Plastic Strip Collator Systems

When pin nail machines get paired with plastic strip collator systems, the result is usually better production flow and higher efficiency on factory floors. Manufacturers find that combining these two pieces of equipment cuts down on manual work involved in collating nails, which means workers spend less time handling materials and production speeds pick up quite a bit. Some shops report cutting down production times by around 30% after making this switch. The benefits go beyond just speed too. Operators tend to experience less fatigue since automation takes over many repetitive tasks. Looking at actual implementations across different manufacturing plants, there's clear evidence that companies save money while also creating safer working conditions. These real world results make a strong argument for why more manufacturers should consider integrating these complementary technologies into their operations.

Choosing Between Hydraulic and Pneumatic Designs

Picking between hydraulic and pneumatic nail machines involves looking at a few important things like price tag, what it'll be used for, and how much upkeep it needs. Hydraulic models generally pack more punch and work great for big production runs, though they come with higher maintenance demands. Pneumatic options tend to be cheaper upfront and simpler to maintain, but just aren't built for the same heavy lifting as their hydraulic counterparts. Most pros will tell anyone who asks that the best choice really comes down to what exactly the shop needs day to day and where they see themselves in five years. These performance gaps matter a lot when making buying decisions. Shops need to weigh what they pay initially versus what keeps happening month after month with repairs and keeping everything running smoothly.

EN

EN

AR

AR

BG

BG

CS

CS

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

LT

LT

SR

SR

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

AZ

AZ

KA

KA

BN

BN

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

KK

KK

UZ

UZ