Wire Drawing and Flattening Machine Basics

Key Components and Functionality of Wire Drawing Machines

Essential Parts: Dies, Rollers, and Tension Systems

A wire drawing machine relies on several key parts that directly affect how good the finished wire turns out. First up, the die itself matters most since it sets the final size and smoothness of the wire product. When properly engineered, these dies keep the wire consistent all the way through production. Then there are those rollers that guide the wire along while cutting down on friction during processing. They actually help protect both the wire material and the machine from excessive wear over time. Don't forget about tension systems either they apply just enough pressure to stop wires from snapping but still maintain even stretching throughout. Put all these elements together and manufacturers get reliable output of quality wire day after day across different applications.

How Wire Flattening Complements Drawing Processes

When manufacturers incorporate wire flattening right into their drawing processes, they actually get some pretty good improvements across many different industrial applications. One main advantage comes from increasing the surface area of these wires, something that matters a lot in electrical work because it helps boost conductivity. Combining both drawing and flattening cuts down on how many separate steps there are during wire production, making everything run smoother overall while cutting down on those frustrating downtimes between operations. Think about what this means for sectors such as automotive manufacturing or electronic component fabrication, where custom shaped wires just aren't optional anymore. Plus, this combined approach lets producers create wires in all sorts of specific sizes and forms that match exactly what each particular application demands.

The Role of Wire Preparation in Efficient Operation

Getting the wire ready properly before running it through a drawing machine makes all the difference for smooth operations and good quality end products. Most of the time, workers need to clean off any dirt or debris and then heat treat (anneal) the wire so it bends better without breaking. When this prep work gets done right, there are fewer flaws in the finished wire and everything runs much smoother during the actual drawing process. Skipping these steps can lead to all sorts of problems down the line, including inconsistent thicknesses across batches. Shops that keep their preparation routines up to date tend to see fewer machine breakdowns and happier customers who get exactly what they ordered. A little extra time spent on proper preparation pays off big time in the long run.

Types of Wire Drawing Machines Explained

Straight Line Carbon Wire Drawing Machines

Straight line carbon wire drawing machines come with a pretty basic setup that really boosts how well carbon wire processes work. Their straightforward design cuts down on all the extra moving parts inside, which means less stress on the machine components over time. Because of this, they tend to last longer without breaking down, which is why many factories prefer them when they need something reliable and easy to maintain. The linear arrangement helps keep the wire tension consistent throughout production while also meaning fewer parts need replacing regularly. This translates into real money saved for manufacturers who run these operations day after day.

Pulley-Type vs. Water Tank Machines

Wire drawing machines that use pulleys work by employing multiple pulley systems which actually makes the whole wire drawing process faster and more efficient than other methods. The way these pulleys function helps maintain just the right amount of tension while feeding the wire through at optimal rates, which means factories can produce much more wire in less time. On the other hand, water tank machines tackle different problems altogether. These units are built specifically to handle all the heat buildup and lubrication issues that happen when wires get drawn through metal. With proper temperature control and enough lubricant flowing throughout the system, the dies and rollers last way longer before needing replacement. When looking at equipment options, it really pays off for manufacturers to understand how these two machine types operate differently because picking the wrong one can lead to wasted resources and lower productivity over time. Those interested should check out our detailed information on pulley type wire drawing machines for specifics.

Specialized Extremely Fine Wire Systems

Wire systems designed for ultra fine production can create wires measuring just a few micrometers across something truly remarkable when considering their practical applications. Making this possible demands both meticulous engineering and cutting edge tech since working with such tiny materials presents unique challenges during the drawing process itself. Manufacturers have developed several clever solutions over time including specialized coatings and tension control mechanisms that significantly reduce breakage rates while maintaining quality throughout entire batches. These machines find their way into industries where even minor dimensional variations could spell disaster for end products like telecommunication components, intricate medical equipment, or aircraft structural parts. Without reliable wire manufacturing capabilities, many modern technological advancements simply wouldn't exist. Want to see exactly how these sophisticated systems operate? Check out our detailed breakdown at Extremely Fine Wire Drawing Machine.

Critical Features for Optimal Performance

High-Strength Alloy Construction

High strength alloys used in building wire drawing machines really stand out when it comes to lasting power against wear and tear. The materials themselves are built tough enough to handle all sorts of punishment from constant running and heavy loads found on factory floors every day. Machines made this way just don't break down as often or need fixing so frequently. For plant managers, this means fewer production stoppages and less money spent on repairs over time. When equipment stays online longer without issues, factories actually see real improvements in both bottom line profits and output numbers across the board.

Precision Control Systems

Today's wire drawing machines come equipped with sophisticated control systems that keep product quality steady across runs. The best part? These systems can tweak things on the fly - adjusting speed and tension as needed to cut down on those pesky defects that always seem to pop up during the drawing process. When paired with automation, these controls really shine. They maintain just the right settings all through production, so every length of wire comes out looking pretty much identical to the last one. This consistency is what manufacturers live for when trying to meet tight spec requirements without breaking a sweat over manual adjustments.

Automation in Modern Wire Processing

Wire processing automation is changing how we handle everything from drawing to flattening wires, since it cuts down on the need for hands-on work. The machines now run on smart software that handles most of the operations, which means fewer mistakes happen during production runs. What's really useful about these automated setups is they gather all sorts of operation data along the way. Manufacturers can look at this information to spot problems early on and make smarter choices about their processes. Some plants have reported cutting waste by nearly 30% after switching to fully automated systems, showing just how impactful these changes can be for both quality control and bottom line results.

Industry Applications and Use Cases

Electrical Wiring Production

Wire drawing machines play a big role in making electrical wiring for homes and businesses alike. When wires go through this process, their key characteristics get shaped properly. Think about things like how well they conduct electricity and whether they bend without breaking. Getting these right matters because poor conductivity can lead to dangerous situations while low flexibility might cause wires to snap under stress. Most manufacturers follow strict guidelines set by organizations like UL or IEEE to keep everyone safe and make sure everything works reliably. Good quality control throughout the wire drawing process means we end up with cables that actually perform as expected when installed in walls or equipment across different environments.

Nail Manufacturing Processes

The wire drawing process plays a major role in nail manufacturing when it comes to getting the right thickness for both strength and how well the nails actually work. When manufacturers have good control over the wire size, they end up with fewer defective products and longer lasting nails overall. This matters a lot because companies need to keep up with demand while still maintaining quality standards. Modern wire drawing equipment these days usually comes with sophisticated control systems that cut down on material waste and speed things up considerably. For anyone running a nail factory, investing in better wire drawing tech isn't just smart business it's almost necessary if they want to stay competitive in today's market where efficiency means everything.

Aerospace Component Fabrication

Wire drawing machines play a vital role in the aerospace sector when it comes to manufacturing those high strength wires needed to pass strict safety tests. These particular wires end up in components where failure just isn't an option at all. When we talk about wire drawing for aerospace applications, special methods come into play during processing. These methods actually improve the wire's characteristics so it can handle all sorts of stress situations that happen during actual flights. Working hand in hand with aircraft makers allows wire producers to tweak their processes until every single specification set by aviation authorities gets met exactly right. After all, nobody wants to compromise on either safety or how well things perform when building parts for planes and spacecraft.

Maintenance and Operational Best Practices

Lubrication and Wear Prevention

Keeping moving parts properly lubricated helps stop wear and makes wire drawing machines last longer. Using the right kind of oil or grease keeps things running smooth, cuts down on friction, and stops machines from getting too hot when they run for long periods. Regular checkups are important too. Factory managers who schedule these inspections can spot problems before they become big issues, saving money on repairs later. Good maintenance practices keep equipment working at its best while ensuring production doesn't grind to a halt. For businesses in busy manufacturing settings where downtime costs real money, this kind of proactive care makes all the difference between staying competitive and falling behind.

Troubleshooting Common Tension Issues

Spotting tension problems early on in wire drawing machines saves both time and headaches while keeping the final product at consistent quality standards. Most often, these issues stem from wires not following their intended path through the system or when machine settings aren't properly adjusted. Regular maintenance checks every few weeks along with periodic recalibration go a long way toward preventing major disruptions. Operators who have been around the block know that having a good troubleshooting flowchart handy makes all the difference. These guides help technicians address tension troubles fast before they escalate, which keeps machines such as straight line carbon wire drawing systems running smoothly without unexpected downtime.

Extending Machine Lifespan

Putting together a good preventive maintenance plan really makes a difference when it comes to how long wire drawing machines last. Training operators properly matters a lot too. They need to know what adjustments to make regularly and do those daily checks before things start wearing down prematurely. When parts need replacing, going for quality components instead of cheap alternatives pays off in the long run. Machines just perform better overall. And let's face it, in manufacturing settings where precision matters most, especially with something like ultra fine wire drawing equipment, keeping these machines running smoothly isn't just nice to have it's absolutely necessary for staying competitive.

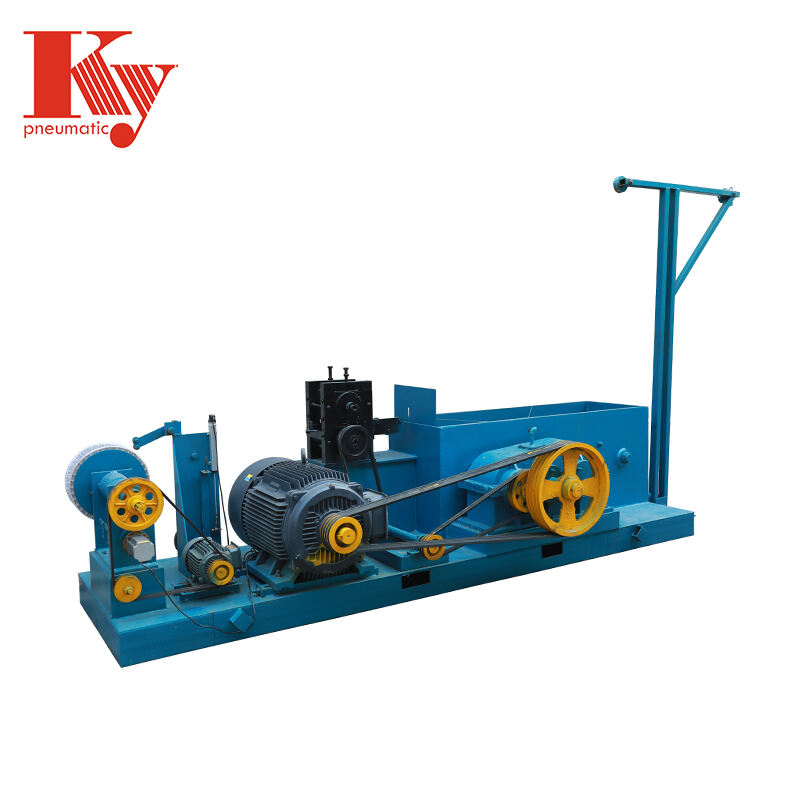

KY Pneumatic Wire Drawing and Flattening Machine

Technical Specifications: 380V Motor & 350-600m/min Speed

The KY Pneumatic Wire Drawing and Flattening Machine comes equipped with a solid 380V motor that delivers plenty of grunt for tough industrial jobs. With this powerful motor under the hood, operators can run the machine at speeds between 350 and 600 meters per minute, which works great in factories where they need to crank out large volumes of product day after day. These kinds of specs mean plant managers don't have to worry about falling short on production targets, all while keeping their operations running smoothly and reliably over long shifts.

High-Precision Flattening Capabilities

This machine incorporates cutting-edge technology that ensures ultra-precise wire flattening, meeting the stringent specifications required in various industrial applications. Enhanced precision not only improves product quality but also minimizes material wastage, contributing to more cost-effective operations. By maintaining consistency and accuracy, it supports manufacturers most demanding flattening projects.

Ideal for Diverse Wire Diameters (0.5-2.0mm)

The KY machine can handle all sorts of wire sizes, anywhere between 0.5mm right up to 2.0mm thick. For manufacturers wanting to offer more products across different markets, this kind of flexibility really matters. When a single machine works with so many diameter options, it becomes something companies just cant do without if they want to grow their operations. Many shops find themselves stuck with multiple machines for different gauges, but the KY cuts through that problem while helping them stay ahead of competitors in the wire manufacturing game.

EN

EN

AR

AR

BG

BG

CS

CS

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

LT

LT

SR

SR

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

AZ

AZ

KA

KA

BN

BN

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

KK

KK

UZ

UZ