Wire Drawing Machines: Ãssential Equipment for Metal Fastener Manufacturing

Understanding Wire Drawing Machines and Their Role in Fastener Production

What Is a Wire Drawing Machine?

Wire drawing machines take metal rods and pull them through a series of smaller and smaller dies to create wires with exact specifications. The cold working method shrinks the rod diameter but actually makes the wire better in several ways at the same time. Surface quality gets smoother, strength increases, and the material becomes more flexible because of how the metal grains get compressed during the process. For manufacturers needing reliable materials, these improvements matter a lot. Today's advanced equipment comes with automatic lubrication systems and tension controls that help maintain consistent quality from one batch to the next without constant manual adjustments.

Core Applications in Fastener Manufacturing

More than seven out of ten screws, bolts, and rivets actually start life as drawn wire. This process gives them really tight dimensional control around plus or minus 0.01 mm, something that's absolutely essential when it comes to how well those threads work together. What's interesting is that during this drawing process, manufacturers can get specific hardness levels right up to 450 HV for carbon steel parts, yet still keep enough flexibility so they won't break during cold forging operations. Finding this sweet spot between hardness and workability is what makes wire drawing such a key step in making those corrosion resistant fasteners we see everywhere from cars to airplanes. Without this technique, many of our modern mechanical systems just wouldn't hold together properly under stress.

Transforming Raw Steel into Fastener-Grade Wire

The process begins when manufacturers anneal raw steel to get rid of those pesky internal stresses. After this step comes acid pickling which strips away all the unwanted surface oxides. What happens next is pretty interesting too. Through multiple stages of drawing, they can actually reduce the rod diameter by as much as 90 percent. But wait there's more! They need to do some intermediate annealing along the way to keep things from getting too brittle. According to research published last year by the International Wire Association, wires that go through proper drawing processes show about 30% better tensile strength compared to their hot rolled counterparts. And finally, after all these steps, comes passivation treatment. This creates that nice even oxide layer on top, making sure everything meets those important ASTM F2329 requirements for how coatings stick to galvanized fasteners in real world applications.

The Wire Drawing Process: From Steel Bar to Precision Fastener Wire

Preparation: Pre-Treatment and Wire Annealing

Before drawing, steel bars undergo descaling via mechanical brushing or acid pickling to eliminate surface contaminants. Annealing at 600–900°C (1,112–1,652°F) softens the material, enabling uniform deformation and reducing crack risk during drawing. Proper annealing improves ductility by up to 40%, a key factor in producing reliable fastener-grade wire.

Drawing: Reducing Diameter While Increasing Strength

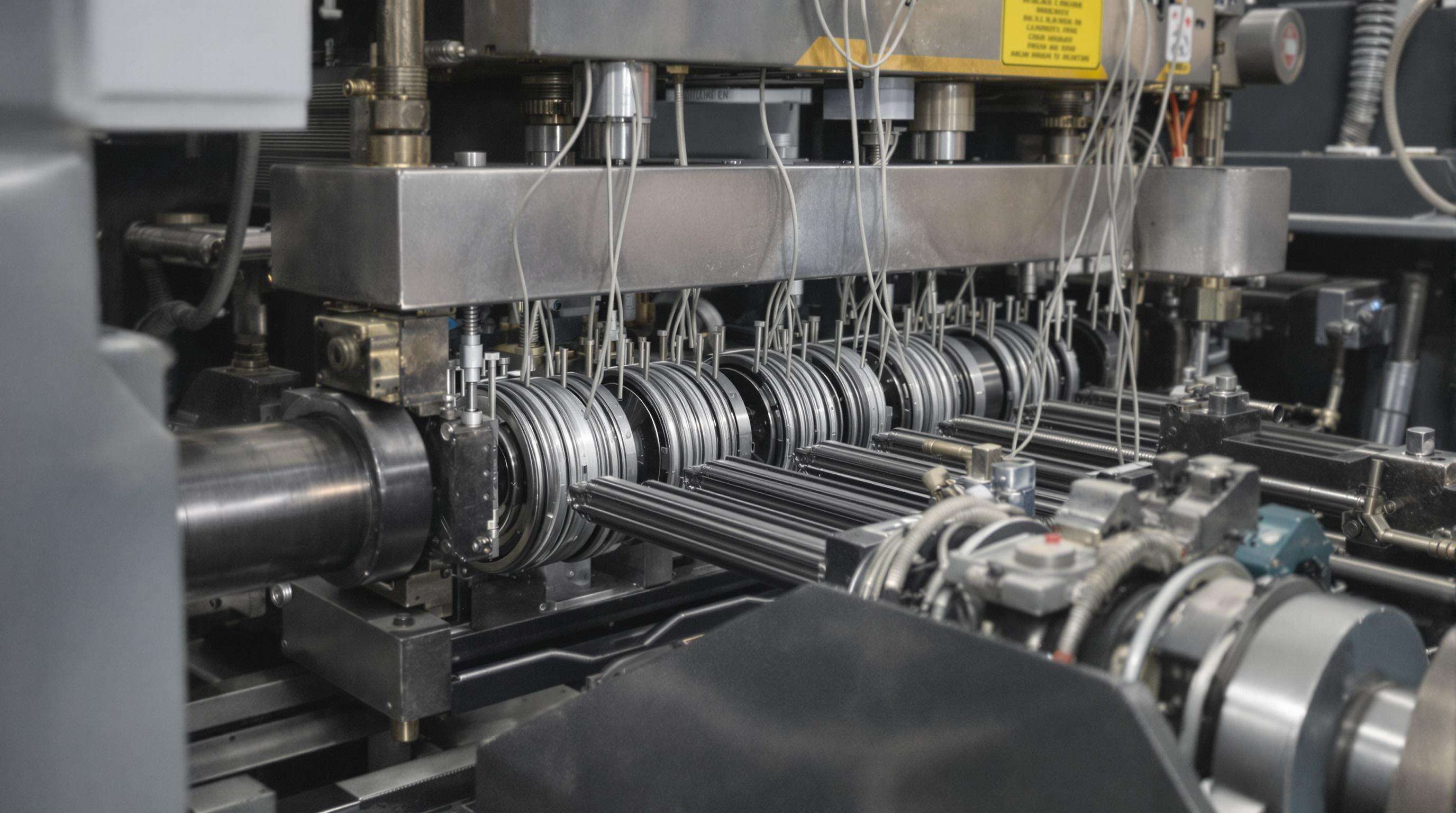

In cold drawing, pre-treated steel is pulled through tungsten carbide or diamond dies, reducing diameter by 15–45% per pass. Strain hardening increases tensile strength by 15–30%, meeting ASTM A510 specifications for fastener materials. Multi-stage machines achieve tight tolerances (±0.01 mm) by progressively reducing wire size across 4–12 dies in a single run.

Lubrication and Cooling to Preserve Wire Integrity

High-speed drawing generates temperatures exceeding 200°C (392°F), risking metallurgical damage. Emulsion-based lubricants reduce friction by 60–70%, while closed-loop water cooling maintains wire temperatures below 120°C (248°F). This dual approach prevents surface galling and preserves the crystalline structure necessary for downstream forming operations.

Winding and Post-Processing for Consistent Output

Servo-controlled spoolers wind wire under 50 N of tension to minimize residual stress. Post-processing steps such as stress-relief annealing or electroplating prepare the wire for heading, threading, and other fastener-forming operations. Automated inspection systems use laser micrometers and surface scanners to achieve 99.9% defect detection rates.

Types of Wire Drawing Machines and Material Compatibility

Single-Die vs. Multi-Die Machines: Output and Efficiency

When it comes to making small batches of specialty alloys, single-die machines work best because they give manufacturers fine-grained control over materials that need constant setup changes. On the other hand, most big volume fastener production relies on multi-die systems. These setups can shrink wire diameters through anywhere from four to twelve dies all at once during a single pass. What makes them so popular? Well, they boost tensile strength somewhere around 20 percent while keeping speeds between fifteen and thirty meters per second. And there's another benefit worth mentioning too. According to research published in the International Journal of Advanced Manufacturing last year, when working with carbon steel fasteners specifically, these multi-die arrangements cut down on energy usage by about eighteen percent compared to going through each die one after another.

Combination Machines and Integrated Drawing Lines

Modern combination machines integrate drawing, annealing, and coating into unified systems, minimizing handling-related surface defects. Integrated lines for stainless steel fasteners achieve 95% material yield through closed-loop lubrication and real-time diameter monitoring. Such systems reduce cross-line downtime by 25–40% compared to modular setups.

Matching Machine Type to Carbon Steel, Stainless Steel, and Non-Ferrous Alloys

| Material | Optimal Machine Type | Key Consideration |

|---|---|---|

| High-carbon steel | Multi-die straight-line | Die wear resistance & cooling |

| Stainless steel | Water-cooled vertical | Oxidation prevention |

| Copper alloys | Single-die with soft dies | Minimizing work hardening |

| Titanium | Vacuum chamber-equipped | Temperature control below 400°C |

Hardened carbon steels require tungsten carbide dies and forced-air cooling to maintain dimensional stability, while copper alloys demand slower drawing speeds (<10 m/s) to preserve electrical conductivity.

Achieving Optimal Surface Finish and Mechanical Properties for Fasteners

Wire drawing machines enable precise control over mechanical and surface characteristics, transforming raw metal into high-performance fastener-grade wire through calculated deformation and integrated quality assurance.

Enhancing Tensile Strength and Ductility Through Cold Drawing

Cold drawing boosts tensile strength by 15–30% via dislocation density increase, while retaining necessary ductility. A 2023 metallurgical study showed that carbon steel drawn at a 40% reduction rate achieved 1,050 MPa tensile strength with less than 8% elongation loss—ideal for vibration-resistant bolts.

Surface Quality Control to Prevent Cracking in Screws and Bolts

Inline laser profilometers detect surface flaws as small as 5 μm, eliminating stress concentration points in finished fasteners. According to industry benchmarking, this reduces thread cracking by 92% in automotive suspension bolts.

Balancing Draw Speed and Material Integrity

Advanced servo-controlled systems maintain drawing speeds between 8–12 m/s for stainless steel, avoiding excessive work hardening beyond recrystallization limits. Real-time temperature sensors trigger coolant adjustments within 0.3 seconds, ensuring microstructural uniformity across batches.

Integrating Wire Drawing Machines into Industrial Fastener Production Lines

Connecting Upstream and Downstream Manufacturing Stages

Wire drawing machines bridge raw material preparation and final fastener forming. They accept descaled and annealed steel rods from upstream processes and deliver precision-drawn wire to cold forging or threading equipment. This integration reduces handling errors by 22% (World Bank 2023) and maintains tight tolerances required for ISO-certified production.

Automation and Real-Time Control Systems in Modern Lines

Industry 4.0-ready systems feature PLC-controlled tension management and self-calibrating dies. A 2024 analysis of U.S. manufacturing trends shows automated lines achieve 18% higher throughput than manual setups by optimizing key parameters:

| Parameter | Manual Control | Automated System |

|---|---|---|

| Speed Variation | ±15% | ±3% |

| Lubricant Usage | 12 L/hour | 8.5 L/hour |

| Energy Consumption | 45 kWh/ton | 38 kWh/ton |

Data-Driven Monitoring for Quality and Efficiency

Integrated sensors monitor over 30 variables, including surface roughness (Ra ≤ 0.8 μm) and tensile strength (1,100–1,400 MPa). Advanced systems use vibration analysis to predict die wear up to 72 hours in advance, cutting unplanned downtime by 40%.

Case Study: High-Volume Fastener Plant Performance Optimization

A Tier 1 automotive supplier increased output by 30% after retrofitting its drawing line with IoT-enabled equipment. Real-time ovality monitoring (within 0.02 mm tolerance) and automated spool changers eliminated 92% of threading defects in M8–M16 bolts, significantly improving yield and reducing rework.

FAQ

What are wire drawing machines used for? Wire drawing machines are primarily used to reduce the diameter of metal rods to create wires. They are crucial in fastener production as they ensure precise specifications and improve the mechanical properties of the metal.

How does wire drawing improve the quality of fasteners? Wire drawing enhances fasteners by providing tight dimensional control, increasing tensile strength, and improving surface quality and flexibility. These improvements help fasteners resist stress and corrosion.

What material compatibility should be considered when selecting a wire drawing machine? The machine type should match the material properties. For example, high-carbon steel requires multi-die machines, while stainless steel benefits from water-cooled vertical machines.

EN

EN

AR

AR

BG

BG

CS

CS

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

LT

LT

SR

SR

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

AZ

AZ

KA

KA

BN

BN

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

KK

KK

UZ

UZ