Hog Ring Machine Applications in Furniture, Automotive, and Hardware Industries

Understanding the Hog Ring Machine: Core Components and Industrial Advantages

What Is a Hog Ring Machine?

Hog ring machines are those handy tools that manufacturers rely on in furniture making, car assembly shops, and hardware production to fasten all sorts of stuff together. They work by squeezing those little U-shaped metal rings we call hog rings right through already punched holes, which makes really strong joints that can handle vibrations without coming apart. Compared to regular staples or even sewing threads, these hog ring connections hold up much better when things get shaken around or put under stress. That's why so many factories have switched to them for critical parts where reliability matters most.

Key Components and Working Mechanism

The machine consists of three primary parts:

- Feeder: Automatically supplies hog rings from a magazine

- Nosepiece: Aligns and guides the ring into position

- Actuator: Pneumatic or hydraulic system that crimps the ring

When triggered, the feeder advances a ring to the nosepiece, where the actuator’s jaws compress it around the materials. Leading manufacturers have optimized this process to handle 40–60 rings per minute in production environments.

Functional Advantages of Hog Ring Fastening in Industrial Applications

Hog ring machines provide three critical benefits:

- Enhanced Durability: Connections withstand three times more tension than staples (Industrial Fasteners Journal, 2023)

- Material Versatility: Compatible with leather, rubber, and steel cables up to 5mm thickness

- Process Standardization: Eliminates human error in repetitive fastening tasks

| Hog Ring Type | Best Use Case | Fastening Strength |

|---|---|---|

| C-Type | Automotive upholstery | High (12–15 kN) |

| D-Type | Mattress springs | Medium (8–10 kN) |

| M-Type | Agricultural fencing | Moderate (5–7 kN) |

The technology's adaptability across ring types and materials makes it indispensable for modern assembly lines requiring both precision and speed.

Hog Ring Machine in Furniture Manufacturing: Enhancing Precision and Assembly Efficiency

Role in Upholstery and Sofa Frame Assembly

When it comes to attaching fabric to those stubborn wooden or metal frames during upholstery work, hog ring machines really shine. These devices keep the fabric tight and even over all those tricky curved surfaces that would drive anyone nuts trying to do manually. The closed loop design actually stops the fabric from slipping around much better than regular staples do. According to some numbers from the Furniture Tech Journal back in 2023, this means factories spend about 18% less time fixing mistakes on sofas. Upholsterers who've switched to these machines tell me they see roughly 33% fewer problems with fabric alignment issues too. Makes sense since nobody wants their precious leather getting messed up while trying to staple something onto an armrest support where stress builds up so easily.

Hog Ring vs. Stapling Systems in Mattress and Seat Production

Staples are still king when it comes to putting together budget furniture, but hog rings actually offer around 40 percent more resistance when it comes to pulling out in things like mattress springs and seat bases. The reason? Hog rings close all the way around 360 degrees, spreading out the force much better than staples do. Staples tend to concentrate pressure in one spot, which can lead to problems over time. Companies that have made the switch to hog rings report seeing about 27% less complaints about joints coming apart in their recliners. Some manufacturers even say they've noticed a big difference in customer satisfaction after making this change to their assembly process.

Automation Trends Driving Hog Ring Machine Adoption in Furniture Lines

Furniture manufacturing facilities these days are starting to adopt robotic hog ring systems that work alongside their CNC cutting tables and connect to ERP inventory systems. These automated setups can handle around 460 fasteners each hour, with pretty good accuracy of about plus or minus 0.3mm. This allows for making custom pieces right when they're needed instead of stockpiling them. According to research published in early 2024 on industrial automation trends, manufacturers who brought in these smart hog ring machines saw their upholstery station expenses drop by roughly $19 per square meter. The savings came mainly from wasting less material and spending less time switching between different tools during production runs.

Automotive Applications: Ensuring Structural Integrity with Hog Ring Fastening

Use in Automotive Seat and Interior Trim Assembly

Hog ring machines offer strong fastening options for car seats, trim pieces inside vehicles, and the seating covers themselves. These devices can attach metal springs together, hold foam padding in place, and secure fabric all while keeping everything tight so seats don't come apart after years of use. What makes them stand out compared to glues or sewing? They stop materials from shifting around, which keeps everything aligned properly even when cars crash into things. According to industry reports from last year, about eight out of ten top car makers now rely on these rings for connecting wires together and attaching fabrics to frame structures because they handle vibrations really well over time.

Pneumatic Hog Ring Tools: 68% Reduction in Assembly Time (Source: SAE International, 2022)

Pneumatic hog ring machines reduce labor-intensive manual processes, slashing seat assembly time by 68% (SAE International, 2022). These tools apply 19–23 kg/cm² pressure, driving high-strength steel rings through multiple material layers in 0.8-second cycles. For high-volume plants, this equates to 2,100+ seats fastened daily per workstation, minimizing bottlenecks in trim-and-cover stages.

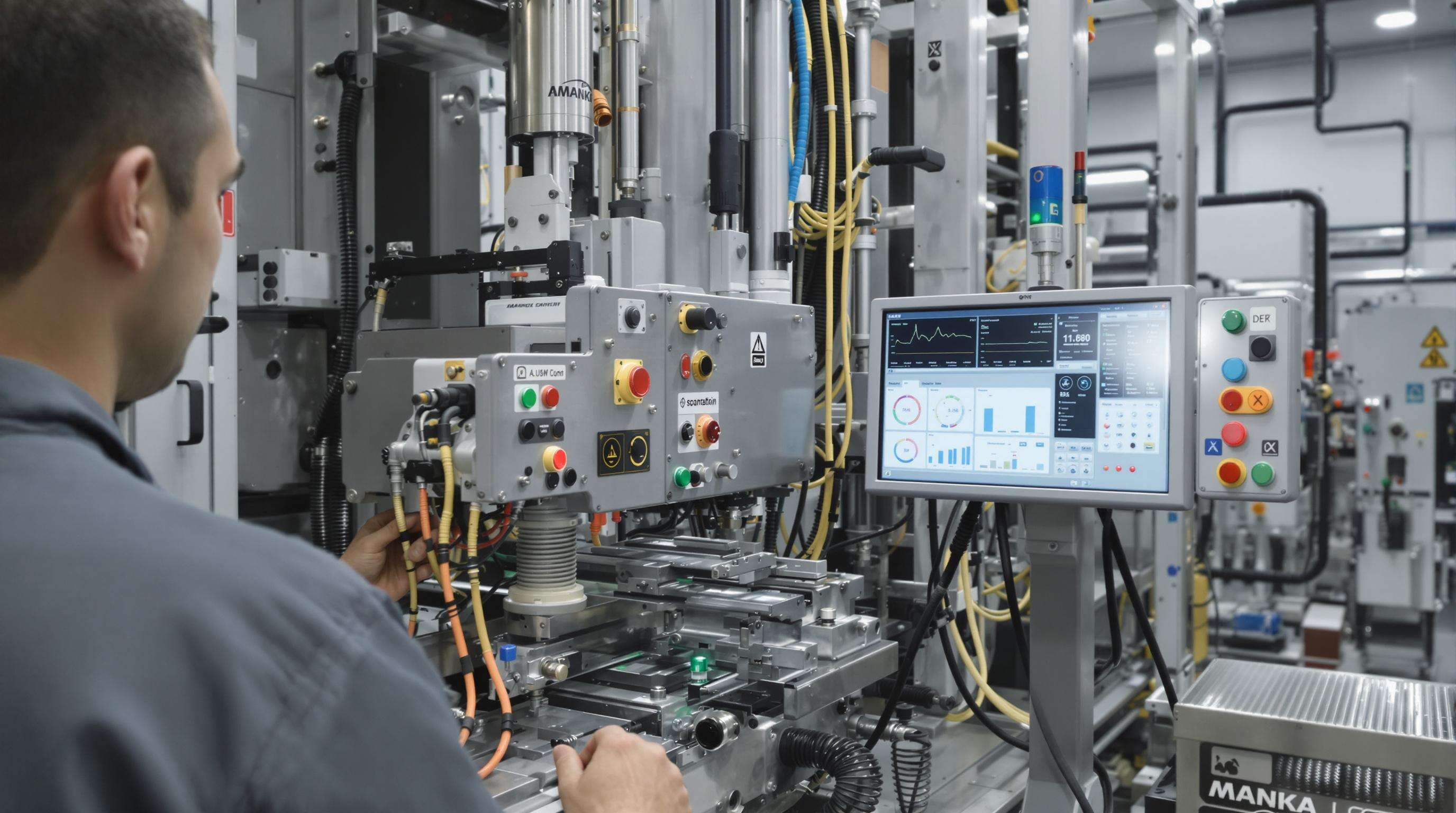

Integration with Smart and High-Volume Production Systems

Today's hog ring machines come equipped with internet-connected sensors that keep track of things like how tightly the fasteners are packed, the tension in the wire, and when tools start showing signs of wear. When these machines work alongside automated framing jigs, they can place those rings with incredible precision - around half a millimeter accuracy actually. This has made a big difference for car manufacturers, cutting down on wasted work by about one third in high end vehicle interior production. The best part? These machines have modular designs that make it easy to install them right into older factory setups. They connect smoothly with enterprise resource planning systems too, which helps manage inventory levels of fasteners and plan maintenance much better than before.

Hardware Industry Uses: Heavy-Duty Fastening in Fencing, Mesh, and Metal Fabrication

Applications in Industrial Fencing and Wire Mesh Assembly

Hog ring machines are really good at putting together those galvanized wire panels used for industrial fencing. They create pretty consistent connections around 3 to 4 mm thick that can handle between 300 and 500 pounds of sideways force according to the National Fencing Association report from last year. What makes these machines stand out compared to spot welding is how they actually keep the protective zinc coating intact on chain link fences. This matters a lot especially near coastlines where salt air eats away at metal so fast. The difference? Studies show about two thirds fewer rust failures when using hog rings instead of welding. Construction crews working on site security fences or warehouse enclosures love these tools because they speed things up dramatically. Workers can snap into place anywhere from 8 to 12 joints every minute without worrying about warping from heat damage which happens all too often with traditional methods.

Heavy-Duty Metal Fabrication with High-Strength Hog Ring Fasteners

The shift from rivets to high carbon steel hog rings with around 5/8 grade tensile strength has become pretty common lately, especially for those non load bearing sheet metal jobs where vibration is a concern. About three out of four such applications now rely on these rings instead of traditional fastening methods. When it comes to HVAC work, most manufacturers go with 8 gauge sizes to connect duct sections together. What makes this approach stand out is how well they create those tight seals that can hold back water pressure equivalent to quarter inch on a gauge. Farmers working on equipment repairs have found another benefit too. These same fasteners work great for attaching 12 gauge steel replacement panels onto combine harvesters. The process takes roughly 40 percent less time compared to dealing with all those M6 bolts, which anyone who's spent hours tightening nuts knows is a real time saver.

Balancing Speed and Joint Integrity in Hardware Production

The latest pneumatic hog ring tools operate around 12 to 14 psi and can secure those 1.5 mm steel brackets onto pallet racking uprights at about 22 joints per minute while keeping gaps below 0.1 mm tolerance. These tools come equipped with smart depth sensors that stop both under and over clamping problems. The result? Much less need for fixing bad joints later on. We're talking about cutting down rework rates dramatically from 15% all the way down to just 2%, which matters a lot when working on things like fire escape ladders where safety is absolutely critical. Field workers who've switched to these tools are seeing roughly 54% better productivity compared to old fashioned manual stapling methods during security door mesh installation work according to data published in Hardware Manufacturing Quarterly back in 2023.

Technological Evolution: From Manual to Smart Hog Ring Machines

Transition from Manual to Pneumatic and Electric Systems

Hog ring machines have come a long way since the days of hand cranked tools that wore out workers after just a few hours on the job. Today's models are either pneumatic or electric, which means operators don't get as tired and production speeds go way up. Pneumatic versions can crank out anywhere from 800 to 1,200 fasteners each hour, which is roughly three times faster than what someone could do by hand. Electric models are especially useful where noise matters, such as in car manufacturing plants where quiet operations are important. What makes these newer systems really stand out is their ability to apply the same amount of pressure (around 12 to 15 Newtons) no matter what kind of material they're working with. This consistency is a game changer when putting together furniture frames made from different materials.

Smart Sensors and Real-Time Feedback in Modern Hog Ring Tools

IoT sensors are being integrated into manufacturing processes these days to keep an eye on things such as how fasteners line up and what kind of compression force they experience. These smart systems then tweak their settings all by themselves using those fancy machine learning algorithms we hear so much about. According to research published by SAE International back in 2022, when applied specifically during seat assembly operations, this tech actually manages to cut down on wasted fasteners by around 18 percent thanks to its ability to predict errors before they happen. Operators get real time dashboards showing them detailed information about each production cycle. With access to these analytics, maintenance teams can spot potential problems early on. The result? Factories making wire mesh report roughly 22% less downtime overall because issues get addressed before equipment breaks down completely.

Sustainability: Reducing Material Waste in Fastening Processes

The smart hog ring machines out there today are really cutting down on wasted materials thanks to those fancy AI nesting algorithms they run. These systems figure out exactly where to place each fastener, which makes all the difference when it comes to saving money on materials. According to what we're seeing across the industry, companies report around 31% less metal wire going into fencing projects now versus when workers had to do everything by hand. And let's not forget about those closed loop pneumatic systems either. They basically recycle most of the compressed air back into the system instead of letting it escape. Some top models get close to 90% recirculation rates, which is why so many factories complying with EU Stage V emissions standards are switching over to these newer machines.

FAQ Section

What industries commonly use hog ring machines?

Hog ring machines are widely used in industries such as furniture manufacturing, automotive assembly, and hardware production. They are particularly valuable for tasks that require secure fastening and precision.

How do hog ring machines enhance durability?

Hog ring machines provide enhanced durability by distributing force evenly around the material, reducing the risk of joints pulling apart under tension compared to traditional fastening methods like staples.

Are hog ring machines compatible with various materials?

Yes, hog ring machines are compatible with a variety of materials including leather, rubber, and steel cables, making them versatile in industrial applications.

What advantages do pneumatic hog ring machines offer?

Pneumatic hog ring machines offer significant advantages such as reduced assembly time, high-pressure application, and increased production efficiency, especially in high-volume environments.

How do smart sensors improve hog ring machine operations?

Smart sensors integrated with hog ring machines provide real-time feedback and adjust settings automatically using machine learning algorithms, improving precision, reducing material waste, and detecting potential errors proactively.

EN

EN

AR

AR

BG

BG

CS

CS

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

LT

LT

SR

SR

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

AZ

AZ

KA

KA

BN

BN

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

KK

KK

UZ

UZ