Wire Gluing Machines: Enhancing Adhesion in Fastener Manufacturing Processes

Core Functionality of Wire Gluing Machines

Wire gluing machines handle the job of applying adhesives automatically in fastener manufacturing processes. They can either replace traditional mechanical fastening methods or work alongside them depending on what makes sense for production needs. The machines come equipped with sophisticated dispensing systems capable of applying various types of adhesives like epoxies, those super strong cyanoacrylates we all know from our toolboxes, and even structural adhesives too. What's really impressive is how precisely these systems operate at the micron level. The nozzles are temperature controlled so the adhesive doesn't start curing before it should, and there's this programmable dosing feature that helps get consistent coverage even when dealing with wires that aren't perfectly shaped. Without this kind of precision, manufacturers would end up with weak spots in their bonded joints which is obviously not good news for parts that need to hold weight or withstand stress. Think about automotive chassis components or those critical aerospace brackets where failure isn't an option.

Integration into High-Speed Fastener Assembly Lines

Today's wire gluing machines work really well alongside CNC wire forming presses and those robotic arms that grab and place components. They can complete each part in under two seconds flat. When it comes to making battery trays for electric vehicles, these bonding systems are putting out around 1,200 busbar connections every hour. That's about 40 percent quicker than what used to be possible with old school riveting methods. The real magic happens with closed loop feedback technology that tweaks adhesive flow on its own when materials vary slightly. No need for technicians to constantly stop everything and recalibrate manually, which saves tons of time on the factory floor.

Ensuring Consistent and Precise Adhesive Application

Getting things right consistently matters a lot. Research shows that even small changes matter - just 0.1mm off track with adhesive bead width drops joint strength by around 18%, according to findings from Adhesion Science Journal back in 2022. The best equipment these days comes with laser guided dispensers paired with smart vision systems that check every single bond as it happens. Take one major car parts manufacturer who saw their warranty issues drop nearly 92% once they started using this tech on door handles. They found out that keeping the adhesive amounts spot on stopped problems caused by temperature fluctuations during assembly.

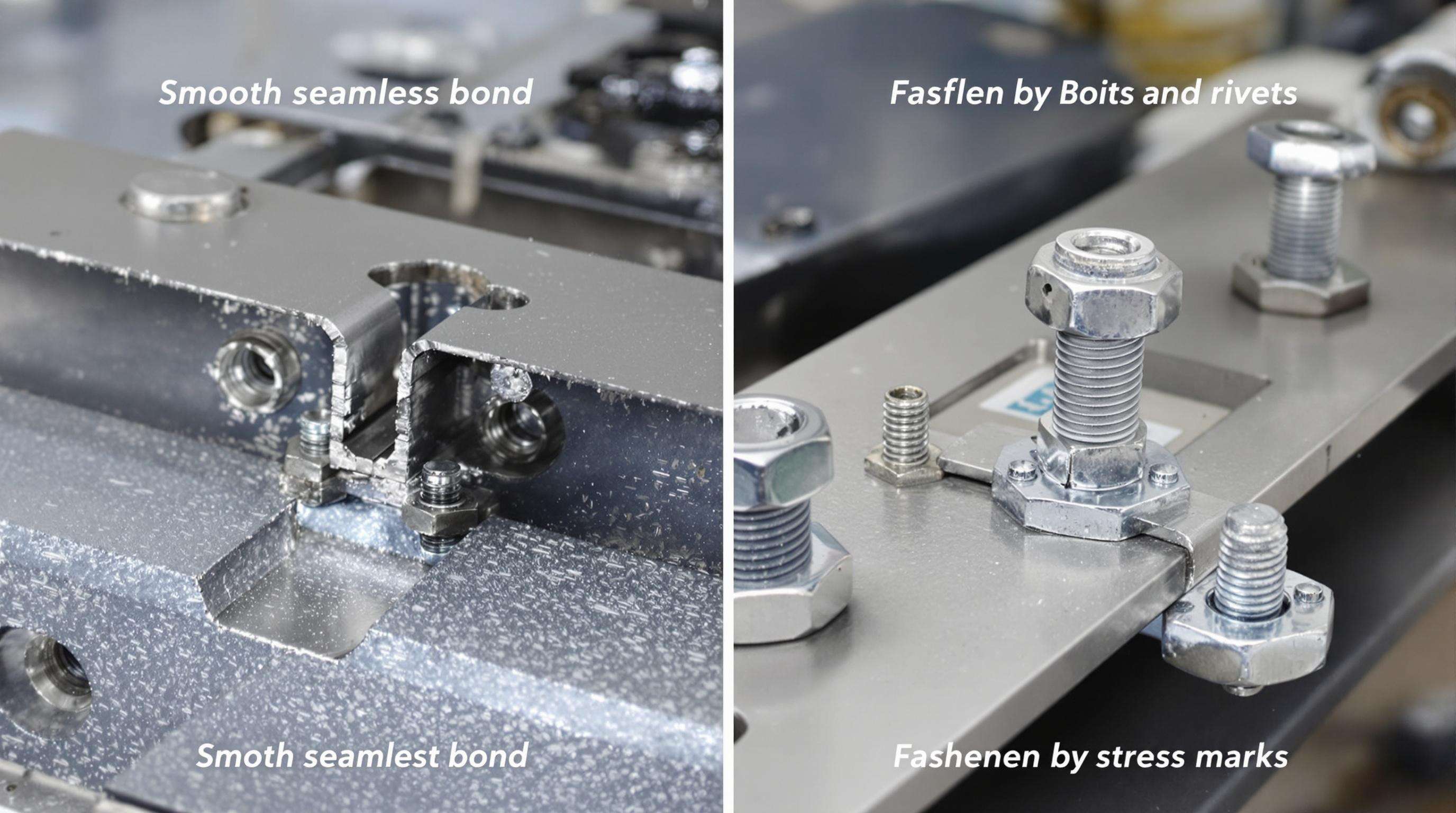

Why Advanced Adhesives Are Replacing Traditional Mechanical Fasteners

More companies are turning to advanced adhesives instead of traditional mechanical fasteners because they cut down on structural weight without sacrificing performance. When parts are bonded together with adhesives rather than riveted, manufacturers typically see around a 25% reduction in component weight. Plus, these bonds don't have those pesky stress concentration points that bolts and rivets tend to create. The change toward adhesives has really taken off in sectors like cars and planes, especially when dealing with tricky combinations like attaching carbon fiber components to aluminum frames. A study published in Nature last year showed something interesting too: adhesives spread stress much more evenly across surfaces. This means products subjected to constant vibrations face about 40% fewer chances of breaking down from fatigue over time. For engineers designing everything from airplane wings to electric vehicle bodies, this kind of reliability makes all the difference.

Adhesively Bonded Structures vs. Mechanical Fastening: A Performance Comparison

| Factor | Adhesively Bonded Structures | Mechanical Fastening |

|---|---|---|

| Weight Impact | Reduces total weight by 15–25% | Adds fastener weight |

| Stress Distribution | Even load transfer across surfaces | Concentration at fastener points |

| Material Flexibility | Bonds dissimilar materials seamlessly | Limited to compatible metals |

| Installation Speed | 30% faster application | Drilling/threading required |

Automakers report 22% faster assembly times using wire gluing machines for adhesive application compared to traditional fastening workflows.

Balancing Strength, Flexibility, and Reliability in Adhesive Joints

The latest generation of structural adhesives blends the toughness of epoxy with the flexibility of polyurethane materials, resulting in impressive tensile strength ratings around 35 MPa or better while still handling different rates of thermal expansion between materials. When applied to electric vehicle battery trays, these advanced adhesives keep their seals intact even after going through thousands of temperature changes from as cold as -40 degrees Celsius all the way up to 85 degrees. Testing shows they last roughly three times longer than traditional gasketed joints under similar conditions. Manufacturers are increasingly looking for dual cure options combining UV light and heat activation because this approach works well in tricky shapes and corners where standard methods fail, plus it doesn't slow down assembly line operations too much compared to older techniques.

Automation and Precision: How Wire Gluing Machines Enhance Adhesive Application

Enabling Automation with Controlled Adhesive Dispensing

Wire gluing machines can hit position marks pretty accurately, around plus or minus 0.1 mm thanks to their programmable dispensing systems. These machines come equipped with built-in sensors that check the adhesive's thickness and reservoirs that stay at the right temperature. This helps keep the glue flowing smoothly at rates between 20 and 45 milliliters per minute. They work well with different types of materials too, including those tricky UV curing epoxies and conductive silicones. According to some recent tests in manufacturing settings, these automated systems apply adhesive roughly 3.7 times quicker than when workers do it by hand. What's even better is that there's barely any difference in how thick the glue beads are from one application to another, staying under 2% variation according to data published in the Manufacturing Technology Report last year.

Minimizing Human Error in High-Volume Production

Automated systems reduce adhesive-related defects by 82% in fastener assembly compared to manual operations (Industrial Adhesion Quarterly 2022). Closed-loop feedback dynamically adjusts dispensing pressure and nozzle height, compensating for substrate irregularities in real time. This precision prevents issues like insufficient coverage or glue squeeze-out during high-speed runs exceeding 1,200 units/hour.

Case Study: Efficiency Gains in Automotive EV Assembly Lines

One major electric vehicle company recently started using wire gluing machines to seal battery trays, which slashed their cycle time down dramatically—from around 210 seconds all the way to just 94 seconds. They also implemented vision guided robotics that really made a difference. First pass yields jumped from about 76 percent up to nearly 98.5 percent, while they managed to reduce adhesive usage by roughly a third thanks to better path planning according to the 2023 production audit numbers. These changes ended up saving them approximately four hundred thousand dollars every year on fixing defective units, making it clear why so many manufacturers are turning to automated adhesive systems these days for their EV production lines.

Key Industrial Applications and Growth Trends of Wire Gluing Technology

Wire Gluing Machines in Automotive and EV Manufacturing

Wire gluing machines have become pretty much a must-have in car factories these days, particularly when it comes to making electric vehicles. These machines do an amazing job at applying adhesives exactly where needed for things like battery packs and those super light parts that help cars go further on a single charge while keeping everything structurally sound. Looking at what's happening with new insulation tech for magnet wires shows just how important material science has gotten in all this. Manufacturers need better bonding solutions as they push harder to meet stricter performance requirements for EVs, which means constant innovation across multiple fronts of the production process.

Expanding Use of Adhesives Beyond Fastening: Sealing and Bonding Applications

Today’s adhesive systems serve dual roles—providing structural integrity while delivering sealing functionality. UV-curing formulations achieve full bond strength in 8–12 seconds, making them ideal for moisture-sensitive applications like electrical encapsulation. This multifunctionality has reduced the need for secondary sealing processes across aerospace, medical devices, and consumer electronics.

Market Insight: 68% Increase in Adhesive Usage in EV Assembly (2018–2023)

Adhesive consumption in the EV sector rose 68% between 2018 and 2023, driven by battery innovation and lightweighting initiatives. Automated wire gluing machines support this growth with consistent bead application, ensuring durable bonds in high-vibration environments and compliance with strict automotive safety standards.

Innovations in Adhesive Materials for High-Performance Fastener Systems

Next-Generation Adhesives for Demanding Industrial Environments

When it comes to bonding materials, hybrid adhesives that mix the toughness of epoxy with the stretchiness of silicone actually stick about 42% better than regular glues according to some recent tests done for the aerospace industry back in 2023. We're seeing these special mixes hold up really well in tough situations too. Think about electric vehicle battery casings or parts inside robots that get blasted with temperatures changing over 300 degrees Celsius. Pretty impressive stuff. And there's something even cooler happening now with self healing adhesives. These smart materials can fix tiny cracks all on their own without anyone touching them. After going through multiple stress tests, they still manage to keep around 89% of their original sticking power. That kind of resilience is changing what we expect from modern adhesives.

Thermal and Vibration Resistance in Adhesively Bonded Joints

New blends of epoxy and polyurethane can handle vibrations up to 18G while keeping their strength above 35 MPa, which is about 38 percent better than older adhesives according to a study published last year by industrial bonding experts. Wind turbine blades really benefit from this kind of material since they need to resist constant stress over decades of operation. Real world testing has revealed something interesting too the failure rate caused by vibrations went down dramatically when manufacturers switched to these stable compounds, dropping from around 12% down to just 4.7% across various types of heavy equipment.

Sustainable Adhesives: Eco-Friendly Solutions in Fastener Manufacturing

Adhesives made from industrial hemp are showing real promise as bio-based alternatives to traditional petroleum products. They actually hold up just fine in terms of tensile strength compared to what's currently on the market, plus they slash carbon emissions by around 62%, according to that 2023 Circular Manufacturing Report we've been referencing. Big name car manufacturers have started incorporating these eco-friendly glues into their production lines, with roughly three out of four interior panels now being bonded using this sustainable option. Looking ahead, the market for low-VOC adhesives seems poised for solid growth. Industry analysts predict a compound annual growth rate of about 9.8% until 2028, mainly because environmental regulations keep getting stricter and companies are increasingly focused on meeting their green commitments. Some experts even think this trend might accelerate faster than expected as more consumers demand greener manufacturing practices.

FAQ

What are wire gluing machines used for?

Wire gluing machines are used in fastener production to apply adhesives automatically, enhancing precision in bonding processes.

How do wire gluing machines improve adhesive application?

They ensure consistent and precise adhesive application through sophisticated dispensing systems, temperature control, and programmable dosing features.

Why are advanced adhesives preferred over traditional mechanical fasteners?

Advanced adhesives reduce weight, offer better stress distribution, and enable smooth bonding of dissimilar materials, improving performance in various sectors.

How have wire gluing machines impacted EV manufacturing?

Wire gluing machines have become essential in EV manufacturing, ensuring precise adhesive application for battery trays and lightweight parts, supporting innovation and performance requirements.

EN

EN

AR

AR

BG

BG

CS

CS

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

LT

LT

SR

SR

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

AZ

AZ

KA

KA

BN

BN

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

KK

KK

UZ

UZ