Ключови характеристики на надежден производител на машини за теглене на жила

Техническа експертиза и опит в индустрията

Години специализация в технологията за теглене на желязо

Компанията е изградила здравословен послужен списък през последните над 40 години, като работи специфично с технологии за влакнодърпане, което е причината повечето хора в сектора да ни познават като лидери в индустрията. Постигнахме доста важни етапи по пътя. Вземете например нашата работа по машините за влакнодърпане с висока скорост – те всъщност промениха начина, по който производителите подхождат към ежедневните си операции. Въпреки това за нас е важна и качеството, така че когато най-накрая стартирахме модела MSM86 миналата година, това беше нещо специално за нашите клиенти, които се нуждаеха от надеждна ефективност ден след ден. Много производители ни казаха, че тази машина направила производствените им линии да работят по-гладко от всякога. Редовно сътрудничим и с водещи имена в сектора, включително NIEHOFF и други. Тези взаимоотношения не са просто за лога в брошури – те представляват истинско сътрудничество, от което всички печелят чрез споделени знания и по-добри резултати в областта на влакнодърпането.

Сертификати и съответствие с глобалните стандарти

Сертифицирането има голямо значение, когато искаме да покажем, че ни е грижа за качеството и безопасността. Нашата компания притежава няколко важни сертификата като ISO 9001 и CE, които доказват, че се придържаме към международните насоки за производство. Това не са просто хартиени документи – те помагат за изграждането на доверие у клиентите, които искат да знаят, че продуктите им са безопасни и надеждни. Когато компаниите спазват подобни стандарти, хората по-склонно им вярват. И статистиката потвърждава това – данни показват, че компании, които следват ISO стандартите, постигат около 20% подобрение в обхвата на пазара и международните продажби. За да работи всичко безпроблемно, ние редовно проверяваме всичко от производствените линии до готовите продукти. Този непрекъснат процес гарантира, че оборудването ни остава на високо ниво на представяне и ни поддържа с добро име на различни пазари по света.

Точна инженерия и системи за контрол на качеството

Компоненти за модерни машини за теглене на жила

Компонентите на напредналите машини за влакнодърпане наистина са тези, които осигуряват добри резултати от производствените серии. Повечето модели са оборудвани с неща като влакнодърпачни матрици, шпулни устройства и тези устройства за изправяне на жицата, всички те работят заедно, за да изпълнят задачата правилно. Забелязахме някои интересни промени напоследък, при които производителите започват да използват по-добри материали за тези части. Волфрамовата стомана се превърна в популярен избор за матриците, защото издръжат по-дълго и не се износват толкова бързо. Някои по-нови конструкции също включват електромагнитни танцуващи системи, които помагат за поддържане на точно определено ниво на натягане по време на работа. Фабрика в Охайо наскоро модернизира оборудването си с тези подобрения и отбеляза значителни постижения в качеството на жицата, докато е намалил спиранията за поддръжка. Това показва колко важно е правилното инженерство при изграждането на ефективни системи за влакнодърпане.

Толеранция към грешки и перформансни метрики

Когато става въпрос за машини за влакно, разбирането на толерантността към грешки е от голямо значение за всеки в бизнеса. Всъщност, става дума за това колко грешки могат да се случат по време на процеса на влакното без да се провали крайния резултат. Повечето индустрии се придържат доста строго към правилата при определянето на тези лимити, защото никой не иска да излизат дефекти продукти. Най-добрите производители успяват да поддържат грешките наистина ниски благодарение на сериозната инженерна работа, която се прави зад кулисите. Те следят неща като равномерната сила на влакното през цялата му дължина и дали всички парчета излизат в точно еднакъв размер. Някои фабрики дори следят тези числа ежедневно според определени цели, които са си поставили. Вземете например XYZ Manufacturing – след като са инсталирали по-добри проверки за качество миналата година, те са намалили грешките почти наполовина. Такъв напредък означава по-бързи производствени времена и клиенти, които получават това, за което са платили, без изненади. Като се погледнат тези реални резултати, става ясно защо следенето на тези ключови показатели за представяне остава толкова важно в операциите по влакното.

Възможности за персонализация за различни приложения

Прилагаемост към нуждите на производството на цапки и скоби

Персонализирането на производственото оборудване, за да отговаря на конкретни производствени нужди, прави голяма разлика на днешния конкурентен пазар. Вземете например машините за производство на пирони и скоби – има много начини да ги настроите според реалните нужди на даден бизнес. Повечето производители предлагат различни конфигурации, специални аксесоари и системи за управление, които могат да се програмират за конкретни задачи. Една компания може да иска модификация на машината си, така че тя да може бързо да преминава от производството на различни размери пирони към работа с определени видове телени заготовки. Понякога става въпрос само за леко настройване на дебелината на телта, друг път може да се наложи напълно преобразуване от производство на пирони към скоби. Точно този вид гъвкавост е важен, защото позволява както на малките работилници, така и на големите фабрики да се справят с променящите се изисквания на клиентите, без да се налага да закупуват изцяло нови машини всеки път, когато се променят изискванията.

Персонализирани решения за средни и големи операции

Важно е да се изяснят реалните нужди на операциите от среден до голям мащаб, когато става въпрос за подобряване на индустриалните процеси. Когато се работи с такива операции, добрите решения обикновено започват с внимателен преглед на това, което клиентът иска да произведе, какви машини вече притежава и колко пространство е налично в съоръжението. След като се направи такъв подробен преглед, производителите могат да настроят машините по такъв начин, че наистина да увеличат обема на производството. Много компании съобщават за отлични резултати от индивидуално проектирани машини, което в крайна сметка прави клиентите по-доволни. Тези изработени по поръчка системи лесно се вписват в съществуващите работни процеси, без да предизвикат прекъсвания. Вземете например производствена линия, която позволява на работниците бързо да преминават от една партида продукция към друга. Това намалява загубеното време между отделните цикли и води до увеличаване на дневното производство. Повечето собственици на бизнеси, които избират този подход, установяват, че производствените им съоръжения работят по-плавно, а проблемите, които преди водеха до забавяния, просто изчезват.

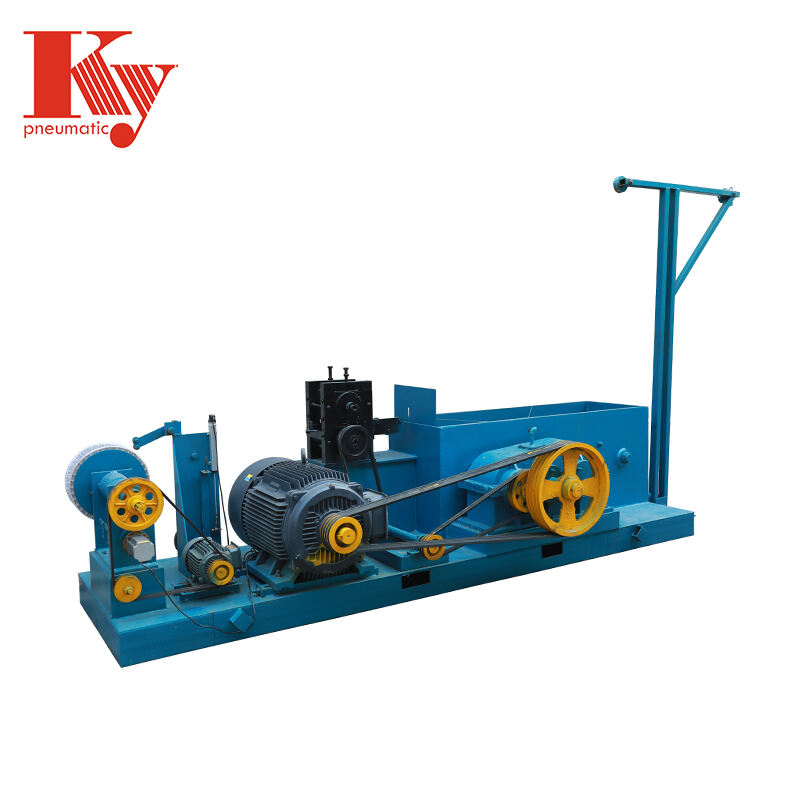

KY Pneumatic Wire Drawing and Flattening Machine

Технически спецификации и прецизност на грешката

Какво прави пневматичната машина за изтегляне и изравняване на жици KY толкова специална? Вижте спецификациите, които осигуряват точност и мощ точно когато трябва. Изградена с издръжлив сплавен обод, тази машина може да се справи с различни видове здрави железни жици, дори и онези досадни видове пружинна стомана, с които другите машини се затрудняват. Най-важното е, че точността ѝ при изравняването остава под 0.001 мм през по-голямата част от времето – нещо, което производителите в индустрията на пирони досега не са виждали. Работници от фабрики, които са използвали тези машини, съобщават, че те просто не спират работа ден след ден без проблеми, докато продължават да произвеждат части, които идеално се събират една с друга. За работилници, занимаващи се с различни типове и дебелини жици, тази машина се справя с всичко – от тънки калибри до по-тежки задачи, без да пропуска нито един ритъм.

Промишлени приложения във заводи за производство на грифи

KY пневматичната машина за изтегляне и разравняване на тел се е превърнала в задължително оборудване в много фабрики за производство на пирони в цялата страна. Изградени предимно за операции от среден до голям мащаб, тези машини помагат на фабриките да произвеждат повече пирони, като в същото време похарчат по-малко средства за материали и труд. Мениджъри на фабрики, които са внедрили тази технология, съобщават, че забелязват реални разлики в ежедневното производство. Един ръководител на завода спомена, че са успели да увеличат седмичното си производство с почти 30% след инсталирането на машината. Това, което я прави толкова ценна, е възможността за персонализиране на параметрите на изтеглянето на телта според различните спецификации за пирони. Някои производители се нуждаят от по-тънки телени жици за специални пирони, докато други изискват по-дебел материал за тежки приложения. Гъвкавостта, вградена в тази система, позволява на производителите бързо да настройват параметрите, без да се налага да инвестират в няколко специализирани машини само за различни продуктови линии.

Полноценна поддръжка след продажбата и обслужване

Глобална мрежа за услуги и наличност на запасни части

Добрата следпродажна поддръжка е от голямо значение, когато става дума за поддържането на машините за производство на нокти в добро работно състояние и по-дълъг експлоатационен срок. Ние сме изградили доста обширна сервизна мрежа по целия свят, така че клиентите да получават помощ по всяко време, независимо къде се намира бизнесът им. Нашите екипи включват опитни техници, работещи от сертифицирани сервизни центрове в различни региони, които са готови да се намесят веднага след като някой закупи една от нашите машини. Наличието на резервни части също е от съществено значение, защото достъпът до компоненти за подмяна означава по-малко загубено време за ремонт. Според някои проучвания, компаниите, които разполагат с бърза система за доставка на резервни части, успяват да намалят простоите на машините си с повече от 50%, което очевидно помага производството да продължава без прекъсвания. Примери от практиката на различни производители също показват, че бързите отклици от нашите сервизни екипи водят до по-добри резултати на производствените площи и в крайна сметка правят операциите по-ефективни всеки един ден.

Програми за обучение на оператори за оптимално използване на машините

Доброто обучение за операторите наистина прави разлика, когато става въпрос да изкарате най-доброто от машините и да сведете до минимум грешките. Ние сме разработили обучение, което дава на хората практически опит, както и необходимите знания, за да работят правилно с оборудването ни за производство на пирони. Курсовете включват както практически умения, така и теоретични познания, които помагат на операторите да се справят с различни предизвикателства по време на ежедневната си работа. Хората, които са завършили програмата, често отбелязват, че резултатите се подобряват веднага – по-малко грешки и по-бързи производствени времена. Когато работниците по-добре разбират машините, те могат постоянно да работят с пълна ефективност, което означава производство на повече продукция без ненужни простои. За компании, които сериозно се стремят да подобрят процесите си при производството на пирони, инвестицията на време и ресурси в подходящото обучение на персонала просто е добър бизнес смисъл.

EN

EN

AR

AR

BG

BG

CS

CS

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

LT

LT

SR

SR

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

AZ

AZ

KA

KA

BN

BN

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

KK

KK

UZ

UZ